Introduction: A Torque Wrench Isn’t a Guessing Stick

Whether you’re tightening bolts on a high-performance engine, installing industrial fasteners, or assembling machinery, using a torque wrench isn’t just helpful – it’s essential. Yet, many users, from DIYers to professionals, still make costly and dangerous mistakes with this precision tool.

In this guide, we’ll dive deep into the 5 most common torque wrench mistakes, how to avoid them, and what you need to know to get the most out of your tool.

Spoiler alert: some of these might surprise you.

What Is a Torque Wrench and Why Is It Important?

A torque wrench is a precision tool used to apply a specific torque to a fastener – usually a nut or bolt. Torque refers to the rotational force, and applying it correctly ensures components are tight enough to function safely and efficiently, but not so tight that they cause damage.

Interesting Fact:

The concept of the torque wrench was invented in 1918 by Conrad Bahr, a New York City Water Department engineer, to prevent over-tightening bolts on water mains.

Quick Overview: Key Features and Technical Specs of a Quality Torque Wrench

Before we jump into the mistakes, let’s look at what makes a torque wrench reliable:

| Feature | Why It Matters |

|---|---|

| Measurement Range | Should match your application (e.g. 10–150 ft-lb) |

| Accuracy | Industry standard is ±4% |

| Scale Type | Digital, beam, or click—each suits different needs |

| Calibration Certificate | Ensures factory-tested accuracy |

| Reversible Ratchet Head | Adds versatility |

| Durable Material | Chrome vanadium steel is a common high-quality option |

| Grip Comfort | Important for precision in long tasks |

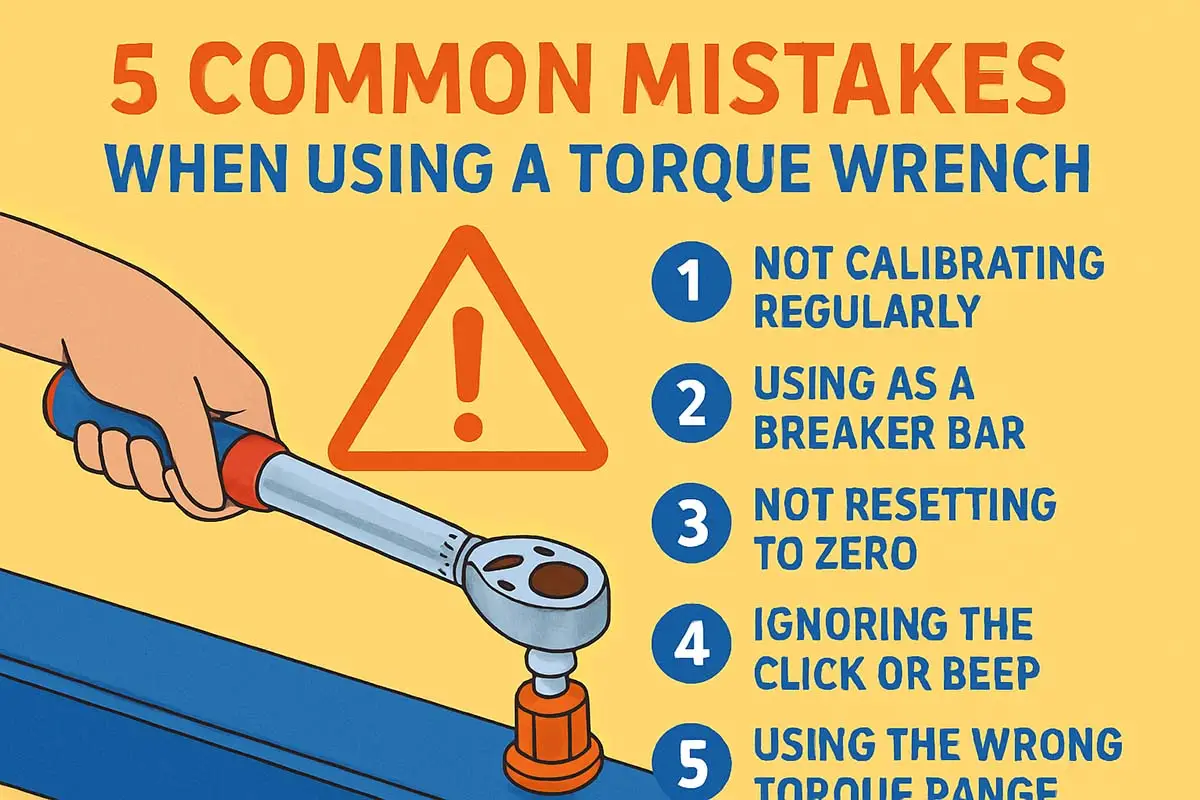

⚠️ 5 Common Mistakes When Using a Torque Wrench

1. Not Calibrating the Wrench Regularly

❌ Why it’s bad:

Torque wrenches lose accuracy over time. If you’re not recalibrating every 6-12 months (or every 5,000 cycles), your readings could be wildly off.

✅ Pro Tip:

Get it professionally calibrated or use a torque tester to verify it’s still within spec. It’s a small investment compared to the cost of a stripped bolt – or worse, a failed assembly.

2. Using the Wrench as a Breaker Bar

❌ Why it’s bad:

Many users think, “Why grab another tool?” and use the torque wrench to loosen bolts. Big mistake! This stresses the internal mechanism and knocks it out of calibration.

✅ Pro Tip:

Use a breaker bar or a standard ratchet for loosening. Reserve the torque wrench only for precision tightening.

🧠 Lesser-Known Fact:

Many torque wrenches are designed to measure torque only in one direction – typically clockwise. Using them in reverse can ruin their accuracy permanently.

3. Not Resetting to Zero After Use

❌ Why it’s bad:

Storing your wrench without loosening the spring tension (on adjustable models) leads to “spring fatigue,” making your readings less reliable over time.

✅ Pro Tip:

After use, wind the torque setting back down to the lowest value (but not below the minimum range). Store it in a dry case, away from temperature extremes.

4. Ignoring the Click or Beep

❌ Why it’s bad:

That click (on a mechanical wrench) or beep/light (on a digital one) is not a polite suggestion. If you keep cranking past it, you’re over-torquing.

✅ Pro Tip:

When you feel or hear the indication, stop immediately. Going past it ruins everything you tried to achieve.

5. Using the Wrong Torque Range

❌ Why it’s bad:

Using a 250 ft-lb torque wrench to tighten a 10 ft-lb bolt is like swatting a fly with a sledgehammer – ineffective and potentially destructive.

✅ Pro Tip:

Always choose a wrench where your target torque is in the middle 50% of its range. It ensures better accuracy and control.

5 Common Mistakes When Using a Torque Wrench FAQ

⚙️ Torque Wrench Usage: Final Tips for Success

- Warm up the wrench with a few practice clicks at a moderate setting before working on critical fasteners.

- Use smooth, steady pressure, not jerky movements.

- Avoid using extensions or cheater bars, which change torque output.

- Mark torque points with a paint pen if you’re doing multiple fasteners.

- Check torque values from the manufacturer – don’t guess!

🛠️ Recap: Mistakes to Leave Behind

Here’s a quick list of mistakes you now know to avoid:

- Skipping regular calibration

- Using the wrench to loosen bolts

- Failing to reset it after use

- Ignoring the torque signal

- Operating outside the torque range

Avoiding these habits will extend your wrench’s life, improve safety, and deliver better results – every time.

🚀 Take Action: Master Your Torque Game

Using a torque wrench correctly isn’t just about tightening nuts and bolts. It’s about building trust – in your equipment, your work, and your outcomes. Whether you’re maintaining a motorcycle, assembling machinery, or bolting down structural components, your torque wrench deserves respect.

Want To Learn More About Torque Wrench?

Find out more information on torque wrenches in the following articles:

- The Ultimate Guide to Torque Wrenches

- How to Use a Torque Wrench in the Automotive Industry

- Automotive Torque Wrench Buying Guide 2025

- Digital vs. Mechanical Torque Wrenches: Which Is Better?

- Best Digital Torque Wrench in 2025

- How to Calibrate a Torque Wrench: Step-by-Step Guide

- Top Torque Wrench Manufacturers Reviewed (2025 Edition)

- How to Set Up a Torque Wrench Correctly (Step‑by‑Step)

- How to Read a Torque Wrench Correctly?

- Torque Wrench Maintenance: How to Extend Its Life

- The Future of Torque Wrenches: Smart Tools & Automation 2025

- Torque Wrenches in Aviation – Case Studies on Safety

- Torque Wrench Safety: Prevent Overtightening & Bolt Failures

- Torque Wrench Accuracy Explained | Understanding Tolerance in Practice

- Digital Torque Wrench Calibration – Step-by-Step Guide 2025

- Snap-On Digital Torque Wrenches (2025) – Premium Review

- Proto Torque Wrenches: Complete Buying Guide & Pro Review (2025 Edition)

- How to Choose the Right Torque Wrench for Your Job

💬 What’s Your Worst Torque Wrench Mistake?

We’d love to hear from you! Have you ever made one of these mistakes – or witnessed a torque disaster firsthand?

👉 Comment below with your experience

👉 Share this post on social media to help others learn the smart way

Let’s spread knowledge – one correctly torqued bolt at a time.