Why Calibrating Your Digital Torque Wrench Matters

Digital torque wrenches are precision tools that measure torque electronically, often using sensors or load cells. Over time, even high-quality wrenches can drift from their original accuracy, affecting bolt tension and potentially compromising safety or equipment performance.

Failing to calibrate can lead to:

- Over- or under-tightened bolts

- Premature wear of mechanical components

- Failed inspections in professional settings

Calibration ensures your digital torque wrench remains reliable, precise, and safe — especially critical in automotive, aerospace, and industrial applications.

For the most accurate results, professional-grade digital torque wrenches should be calibrated at a certified manufacturer or lab. However, for many workshops or home mechanics, in-house calibration using certified standards can maintain accuracy between lab intervals.

⚙️ How Digital Torque Wrenches Work

Digital torque wrenches rely on electronic sensors to measure applied torque. They often include:

- Strain gauges / load cells: Detect mechanical stress

- Microprocessors: Convert stress into digital readout

- Memory functions: Store torque settings and previous readings

- Alerts: Audible or visual signals when torque is reached

Even with robust construction, sensors can drift due to temperature changes, heavy use, or battery fluctuations. Calibration realigns the readout with known torque standards.

⏱ When Should You Calibrate Your Digital Torque Wrench?

Recommended intervals vary depending on use:

| Usage Type | Calibration Interval | Notes |

|---|---|---|

| Industrial / professional | Every 5,000 cycles or 12 months | Lab calibration recommended |

| Workshop / automotive | Every 2,500–3,000 cycles or 6–12 months | In-house or professional calibration |

| Occasional DIY | Every 1–2 years | Simple check against certified torque bolts |

Signs your wrench may need calibration:

- Consistent discrepancy between expected and actual torque

- Inconsistent digital readings

- Physical damage or dropped wrench

- Battery issues affecting display or measurement

🛠 Step-by-Step Calibration Process

Here’s a professional approach for digital torque wrench calibration:

Tools Needed:

- Certified torque calibrator or test stand

- Known standard weights or torque bolts

- Manufacturer’s manual

- Screwdrivers / adjustment tools (if required)

- Zero the Wrench

– Turn on your digital torque wrench.

– Reset to zero using the manufacturer’s procedure.

– Ensure batteries are fully charged for stable readings. - Apply Test Torque

– Use a certified torque standard or calibrator.

– Apply torque incrementally and record the digital readout.

– Compare it to the known torque value. - Adjust Calibration Settings

– If the wrench reading deviates, adjust using the digital adjustment interface or potentiometer (as per manual).

– Store the new calibration setting in memory. - Verification

– Repeat Step 2 after adjustment.

– Ensure readings match within the specified tolerance (usually ±2% for professional digital wrenches). - Record Calibration Data

– Document calibration date, measured values, adjustments made, and next calibration due.

– This creates a traceable maintenance log for professional workshops.

Calibration Methods: DIY vs Professional Labs

| Method | Pros | Cons |

|---|---|---|

| DIY / In-House | Fast, cost-effective, convenient | Limited accuracy, requires certified torque standards |

| Professional Lab | Highest accuracy, documented traceability, ISO/ANSI compliant | Higher cost, may require shipping, downtime |

Recommendation: For professional-grade digital torque wrenches used daily, annual lab calibration is best. DIY checks can supplement between lab intervals.

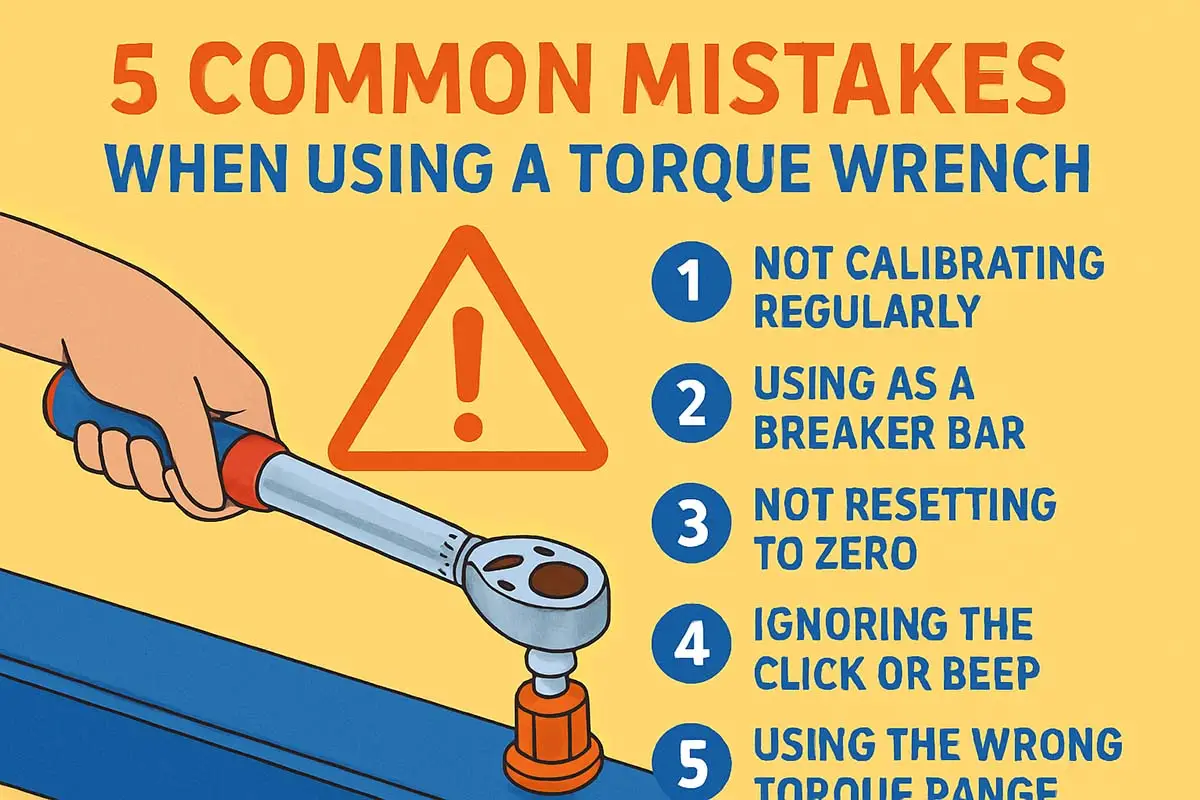

⚠️ Common Errors to Avoid

- Dropping the wrench or applying torque beyond its rated range

- Calibrating with worn or uncertified test equipment

- Ignoring temperature or environmental factors that affect sensor readings

- Using low batteries — weak power can skew results

💡 Tips to Maintain Accuracy

- Always store the wrench at the lowest torque setting

- Keep it in a protective case

- Perform quick checks against a certified torque bolt regularly

- Follow the manufacturer’s recommended calibration schedule

🤔 Funny Fact

Some mechanics joke that digital torque wrenches are like “fussy pets”: they need constant attention, regular check-ups, and a little pampering to keep them happy — or your bolts will rebel!

🔍 Lesser-Known Fact

Digital torque wrenches were first introduced in the 1980s, but modern models now use microprocessor-controlled load cells capable of recording multiple torque cycles in memory — making them indispensable for industrial traceability.

Want To Learn More About Torque Wrenches?

Find out more information on torque wrenches in the following articles:

- The Ultimate Guide to Torque Wrenches

- How to Use a Torque Wrench in the Automotive Industry

- Automotive Torque Wrench Buying Guide 2025

- Digital vs. Mechanical Torque Wrenches: Which Is Better?

- Best Digital Torque Wrench in 2025

- How to Calibrate a Torque Wrench: Step-by-Step Guide

- Top Torque Wrench Manufacturers Reviewed (2025 Edition)

- How to Set Up a Torque Wrench Correctly (Step‑by‑Step)

- How to Read a Torque Wrench Correctly?

- Torque Wrench Maintenance: How to Extend Its Life

- 5 Common Mistakes When Using a Torque Wrench

- The Future of Torque Wrenches: Smart Tools & Automation 2025

- Aerospace Fasteners: Precision, Weight & Vibration Resistance

- Torque Wrench Safety: Prevent Overtightening & Bolt Failures

- Torque Wrench Accuracy Explained | Understanding Tolerance in Practice

- Digital Torque Wrench Calibration – Step-by-Step Guide 2025

- Snap-On Digital Torque Wrenches (2025) – Premium Review

- Proto Torque Wrenches: Complete Buying Guide & Pro Review (2025 Edition)

- How to Choose the Right Torque Wrench for Your Job

✅ Conclusion

Calibrating your digital torque wrench is essential for safety, accuracy, and tool longevity. Whether you choose DIY checks or professional lab calibration, following a systematic process ensures your wrench performs at its best.