🔧 Why Reading a Torque Wrench Right Really Matters

Whether you’re tightening a bolt on a car engine or assembling a machine in your workshop, applying the right torque isn’t just about performance – it’s about safety, accuracy, and preventing damage. Misreading your torque wrench, even by a small amount, can lead to stripped threads, failed parts, or worse – injury.

So, how do you read a torque wrench correctly every single time? Let’s break it down.

📏 What Is a Torque Wrench and Why Should You Care?

A torque wrench is a precision tool designed to apply a specific amount of torque to a fastener such as a bolt or nut. Unlike regular wrenches, it doesn’t just twist; it tells you how hard you’re twisting. This is critical when working with components that require exact tightness – for example, engine cylinder heads, suspension systems, and industrial machinery.

There are four main types of torque wrenches:

- Beam Type

- Click Type

- Digital/Electronic Type

- Dial Indicator Type

Each has its own reading method, accuracy level, and ideal use case.

📘 How to Read Different Types of Torque Wrenches?

1. Beam Type Torque Wrench

- How it works: A pointer moves over a scale as you apply force.

- How to read it: Watch the needle on the scale. The number it points to is your torque.

- Pro tip: Always position your eyes directly in front of the scale to avoid parallax error.

2. Click Type Torque Wrench

- How it works: You set the torque on a handle. When that value is reached, it clicks.

- How to read it: Before using it, set the correct torque value by rotating the handle. Lock it in place, apply torque, and stop once you hear the “click.”

- Critical note: Don’t continue turning after the click. It’s not a drum solo.

3. Digital Torque Wrench

- How it works: Uses sensors to display torque on a digital screen.

- How to read it: Just dial in your required torque. The tool will alert you (often with sound and/or light) once it’s reached.

- Why it’s great: It usually stores data, offers peak hold, and is more accurate.

4. Dial Indicator Type

- How it works: Similar to beam types but uses a dial instead of a pointer.

- How to read it: The needle moves around the dial as you torque. Read the number where the needle stops.

🛠️ Key Features of a Reliable Torque Wrench

When choosing a torque wrench, look for:

- Torque range (e.g., 10–150 ft-lbs or 20–200 Nm)

- Accuracy rating (typically ±3%–4%)

- Reversible ratchet head

- Easy-to-read scale

- Locking mechanism

- Ergonomic handle

- Calibration certificate

Digital models may also offer:

- Preset memory functions

- Backlit displays

- Buzzer/vibration alerts

- Battery level indicators

📊 Torque Wrench Technical Specifications (Example)

| Feature | Specification |

|---|---|

| Torque Range | 10–150 ft-lbs (13.6–203.5 Nm) |

| Drive Size | 3/8” or 1/2” |

| Accuracy | ±3% (clockwise), ±4% (counterclockwise) |

| Calibration | Pre-calibrated to ISO 6789 standard |

| Material | Chrome vanadium steel |

| Handle Type | Non-slip knurled or rubberized grip |

| Warranty | 1–3 years depending on brand |

🤯 Interesting Fact

Torque wrenches were invented in 1918 by Conrad Bahr of the New York City Water Department, who wanted to stop over-tightening bolts on water mains.

🤫 Lesser-Known Fact

Most torque wrenches lose accuracy over time – especially if stored at high torque settings. Always set it back to the lowest value after use to prolong its life and maintain accuracy.

How to Read a Torque Wrench Correctly FAQ

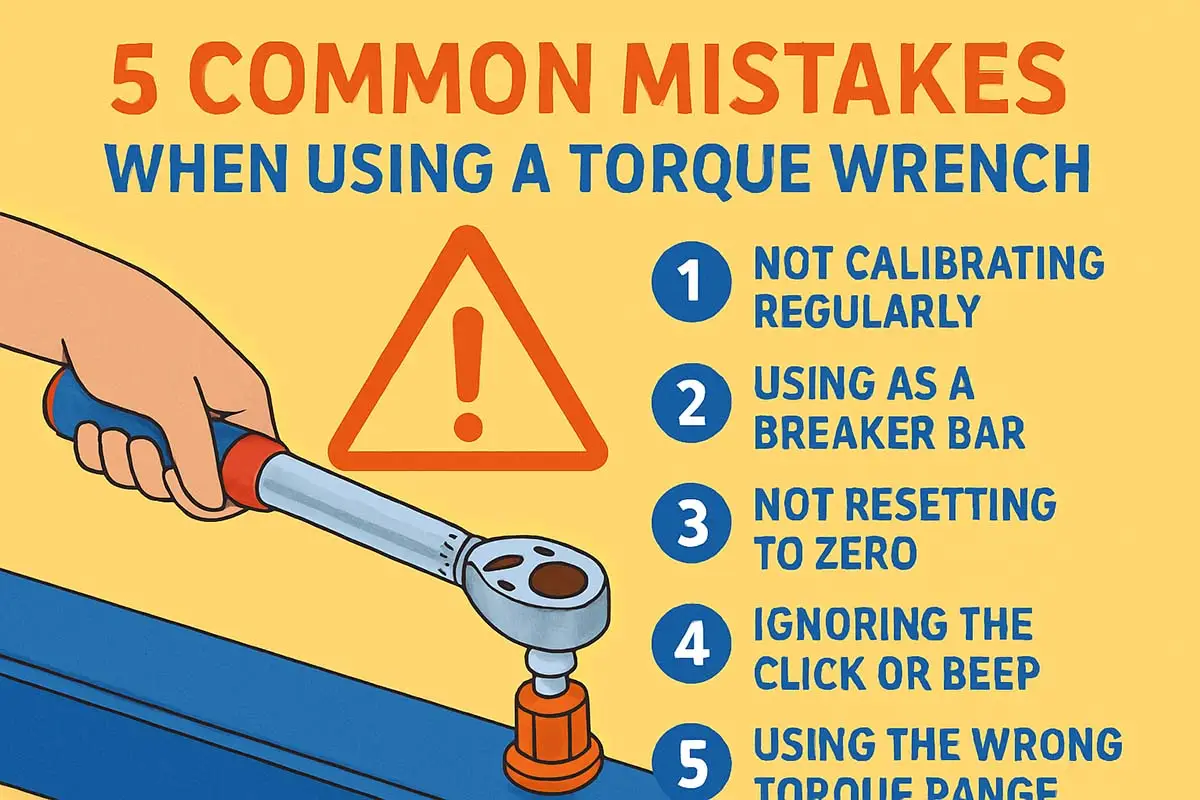

❌ The Bad (That You Shouldn’t Ignore)

- Cheap torque wrenches often have poor calibration and may be wildly inaccurate.

- Click wrenches can be misused if users don’t stop at the click.

- Digital wrenches may fail when batteries die – and they’re not always water- or dust-proof.

- Some scale readings are tiny or poorly marked, which increases the chance of misreading, especially for beginners.

Still, the benefits far outweigh the issues – as long as you buy a quality product and use it properly.

✅ Pro Tips for Perfect Torque Every Time

- Always read instructions first (yes, really).

- Use smooth and controlled movements.

- Don’t jerk the handle.

- Reset the wrench to the lowest value after each use.

- Store it in a protective case.

- Don’t use it as a breaker bar – it’s not built for brute force.

Want To Learn More About Torque Wrench?

Find out more information on torque wrenches in the following articles:

- The Ultimate Guide to Torque Wrenches

- How to Use a Torque Wrench in the Automotive Industry

- Automotive Torque Wrench Buying Guide 2025

- Digital vs. Mechanical Torque Wrenches: Which Is Better?

- Best Digital Torque Wrench in 2025

- How to Calibrate a Torque Wrench: Step-by-Step Guide

- Top Torque Wrench Manufacturers Reviewed (2025 Edition)

- How to Set Up a Torque Wrench Correctly (Step‑by‑Step)

- Torque Wrench Maintenance: How to Extend Its Life

- 5 Common Mistakes When Using a Torque Wrench

- The Future of Torque Wrenches: Smart Tools & Automation 2025

- Torque Wrenches in Aviation – Case Studies on Safety

- Torque Wrench Safety: Prevent Overtightening & Bolt Failures

- Torque Wrench Accuracy Explained | Understanding Tolerance in Practice

- Digital Torque Wrench Calibration – Step-by-Step Guide 2025

- Snap-On Digital Torque Wrenches (2025) – Premium Review

- Proto Torque Wrenches: Complete Buying Guide & Pro Review (2025 Edition)

- How to Choose the Right Torque Wrench for Your Job

🎯 Final Thoughts: Read It Right, Get It Tight

Reading a torque wrench correctly isn’t rocket science – but it is precision work. With the right technique and understanding of your tool, you’ll not only get the job done right, but also extend the life of your components, stay safe, and avoid costly mistakes.

And hey, if you’re into torque specs, you’re probably into doing things properly. That makes you our kind of person. Keep wrenching smart.

💬 Your Turn: Share & Comment!

Have a torque wrench horror story? Or maybe a tip others should know?

Drop your experience in the comments below – let’s talk torque! And don’t forget to share this post on social media to help your fellow fixers get it right the first time.