Introduction

The Husqvarna K 970 Ring Power Cutter is built to last, but let’s be honest: concrete dust, slurry, and heavy workloads can chew through any machine if you don’t give it proper care. Regular maintenance isn’t just about avoiding breakdowns—it’s about cutting better, saving money on repairs, and keeping your cutter safe to use.

This guide walks you through daily, weekly, and long-term maintenance tasks so your K 970 keeps running like a champ.

Why Maintenance is Essential

Think of your K 970 like a high-performance car engine—it thrives with care, but it complains (loudly) if ignored. Here’s what regular maintenance gives you:

- Longer lifespan of both engine and cutting blades.

- Consistent cutting power even in tough materials.

- Lower operating costs (fewer repairs, fewer blade replacements).

- Safer operation, reducing the risk of accidents.

Daily Maintenance Checklist

Perform these steps at the end of every workday:

- Clean the machine. Remove dust, slurry, and debris using compressed air or a damp cloth.

- Inspect the blade. Look for cracks, uneven wear, or glazing.

- Check belt tension. A loose belt reduces power; a too-tight belt wears prematurely.

- Clean or replace air filters. Concrete dust is brutal—don’t let it clog the system.

- Refuel correctly. Use fresh fuel with the correct 50:1 petrol/oil mix.

💡 Pro Tip: Empty fuel from the tank if you won’t be using the cutter for several days. It prevents carburetor gumming.

Weekly Maintenance Checklist

Once a week (or every 20–25 hours of use):

- Check spark plug. Replace if electrodes are worn or fouled.

- Inspect starter cord. Look for fraying or weakness.

- Examine cooling fins. Clean to prevent overheating.

- Check water supply system. Ensure hoses aren’t clogged.

Long-Term & Seasonal Maintenance

If you’re storing the cutter for weeks or months:

- Drain fuel completely. Run the engine until it stops.

- Oil moving parts. Prevents rust during downtime.

- Store in a dry place. Protect from moisture and dust.

- Replace worn parts. Belts, filters, and blades should be fresh before the next job season.

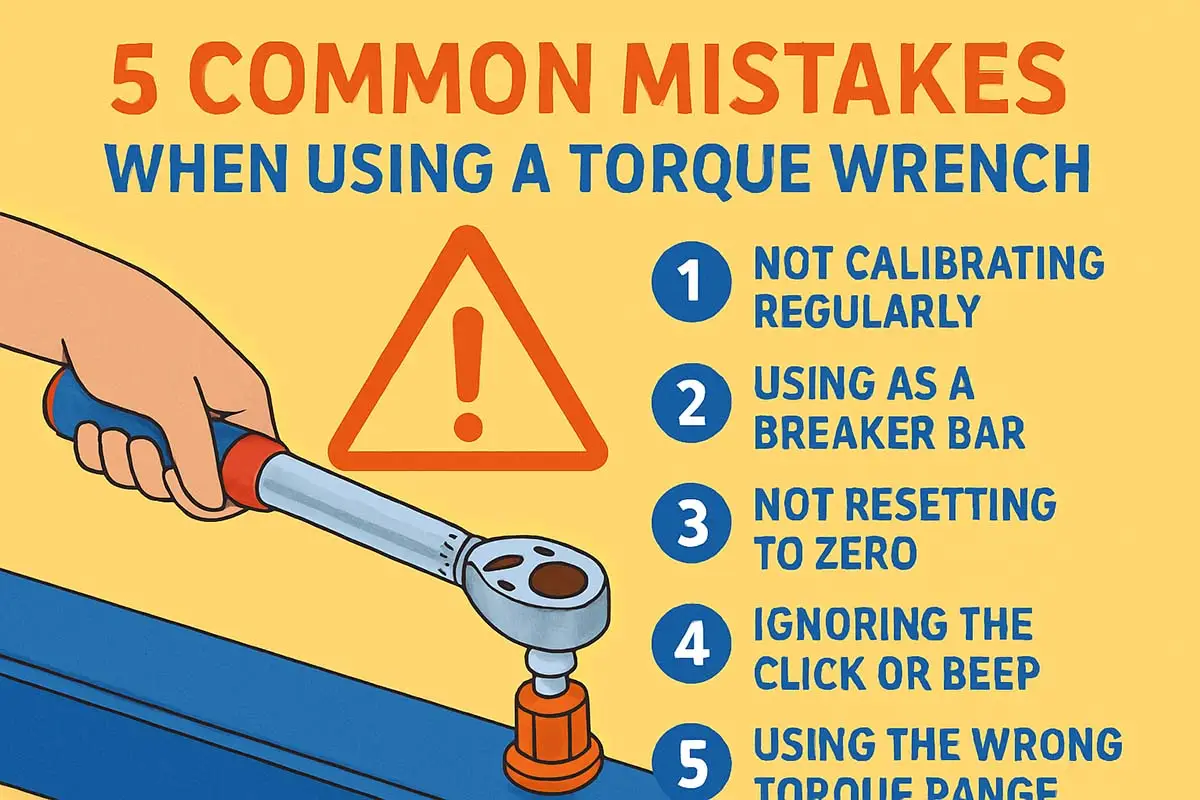

Common Mistakes to Avoid

❌ Running the saw without water cooling when wet cutting.

❌ Using the wrong fuel mixture.

❌ Ignoring filter maintenance.

❌ Forcing the blade through material instead of letting it cut naturally.

Safety and Maintenance Go Hand-in-Hand

Remember: a well-maintained cutter isn’t just efficient—it’s safer. Loose blades, clogged filters, or failing spark plugs don’t just slow you down, they create real hazards on the job site.

Husqvarna K 970 Maintenance FAQ

⚡ Funny Fact: Many contractors complain about the K 970 being “too heavy”—but with proper maintenance, you’ll be cutting faster, meaning you carry it for less time. Problem solved!

📌 Lesser-Known Fact: A clogged air filter can reduce power by up to 30%—many operators mistake this for engine trouble.

Read More About Husqvarna K 970 Ring Power Cutter

- Husqvarna K 970 Ring Power Cutter

- Beginner’s Guide: How to Get the Most Out of the Husqvarna K 970 Ring Power Cutter

- Husqvarna K 970 Ring Power Cutter Maintenance & Care Guide

- Troubleshooting Common Problems with the Husqvarna K 970 Ring Power Cutter

- Husqvarna K 970 Ring Power Cutter Safety Guide: How to Use It Like a Pro

👉 Drop your thoughts in the comments below, and don’t forget to like and share this guide with fellow contractors or DIY enthusiasts who might find it useful. Your experience could save someone else a broken blade (or a headache)!