Heavy farm equipment like tractors, harvesters, and irrigation pumps rely heavily on hydraulic systems to deliver power, precision, and control. Maintaining these systems is critical to avoid costly breakdowns and ensure safe operation.

This post dives deep into the must-have hydraulic maintenance tools, their key features, and practical tips to keep your farm machinery hydraulics in top shape.

Why Hydraulic Maintenance is Critical in Agriculture

Hydraulic systems transfer force through fluid under pressure. Because they operate under high pressure, even a small leak or contamination can cause system failure or safety hazards. Regular maintenance ensures:

- Consistent pressure and smooth operation

- Prevention of leaks and contamination

- Longer equipment lifespan and reduced repair costs

- Safety for operators and the environment

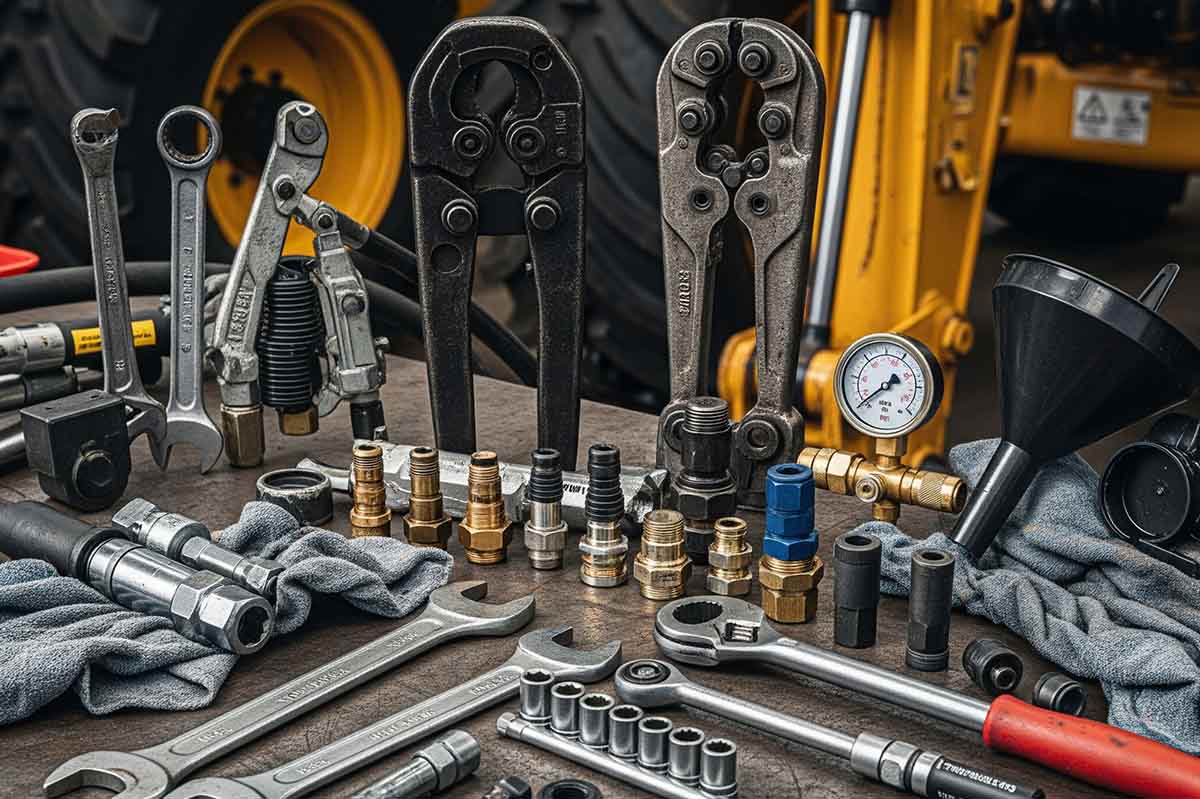

Essential Hydraulic Maintenance Tools for Farm Equipment

1. Hydraulic Pressure Gauge

Purpose: Measures system pressure to ensure it matches manufacturer specs.

Features:

- Compatible with various pressure ranges (up to 6000 psi common)

- Analog or digital displays

- Durable, corrosion-resistant construction

Pro tip: Use during diagnostics to identify leaks or pressure drops.

2. Hydraulic Fluid Test Kit

Purpose: Tests fluid quality, including contamination, viscosity, and water content.

Features:

- Portable kits for field testing

- Simple colorimetric or digital sensors

- Allows early detection of contamination or degradation

Importance: Regular fluid testing prevents premature wear and hydraulic failures.

3. Hose and Fitting Inspection Tools

Purpose: Detect cracks, leaks, or wear on hydraulic hoses and fittings.

Tools include:

- Visual inspection mirrors and flashlights

- Ultrasonic leak detectors

- Hose pressure testers

Best practice: Inspect hoses regularly to avoid sudden bursts or leaks.

4. Hydraulic Filter Wrench

Purpose: Removes and installs hydraulic filters safely without damage.

Features:

- Adjustable sizes for different filter types

- Non-slip grips and durable materials

Tip: Replace filters according to schedule; clogged filters degrade performance.

5. Fluid Extraction Pump

Purpose: Safely removes old or contaminated hydraulic fluid without mess.

Features:

- Manual or electric operation

- Flexible suction tubes

- Compatibility with various fluid types

Pro tip: Always use a clean container to collect fluid for proper disposal.

6. Torque Wrench for Hydraulic Components

Purpose: Ensures hydraulic fittings and bolts are tightened to correct torque.

Features:

- High accuracy and durable build

- Suitable torque range for hydraulic fittings

Importance: Prevents leaks and damage caused by improper tightening.

7. Hydraulic System Bleeding Kit

Purpose: Removes air trapped in hydraulic lines after maintenance or fluid changes.

Features:

- Tubing and valves for controlled bleeding

- Clear reservoir to observe fluid flow

Pro tip: Proper bleeding restores system responsiveness and prevents erratic operation.

Best Practices for Maintaining Hydraulic Systems on the Farm

- Regular Inspections: Check hoses, fittings, and fluid condition frequently.

- Keep it Clean: Prevent contamination by using clean tools and clean environment during maintenance.

- Follow Fluid Change Intervals: Use manufacturer-recommended hydraulic fluids and replace as scheduled.

- Use Correct Torque: Always tighten fittings with calibrated torque wrenches.

- Proper Bleeding: Remove air to maintain system efficiency and avoid spongy controls.

Interesting Fact

A small hydraulic leak can waste hundreds of liters of fluid per season — not only costly but also harmful to the environment.

Lesser-Known Fact

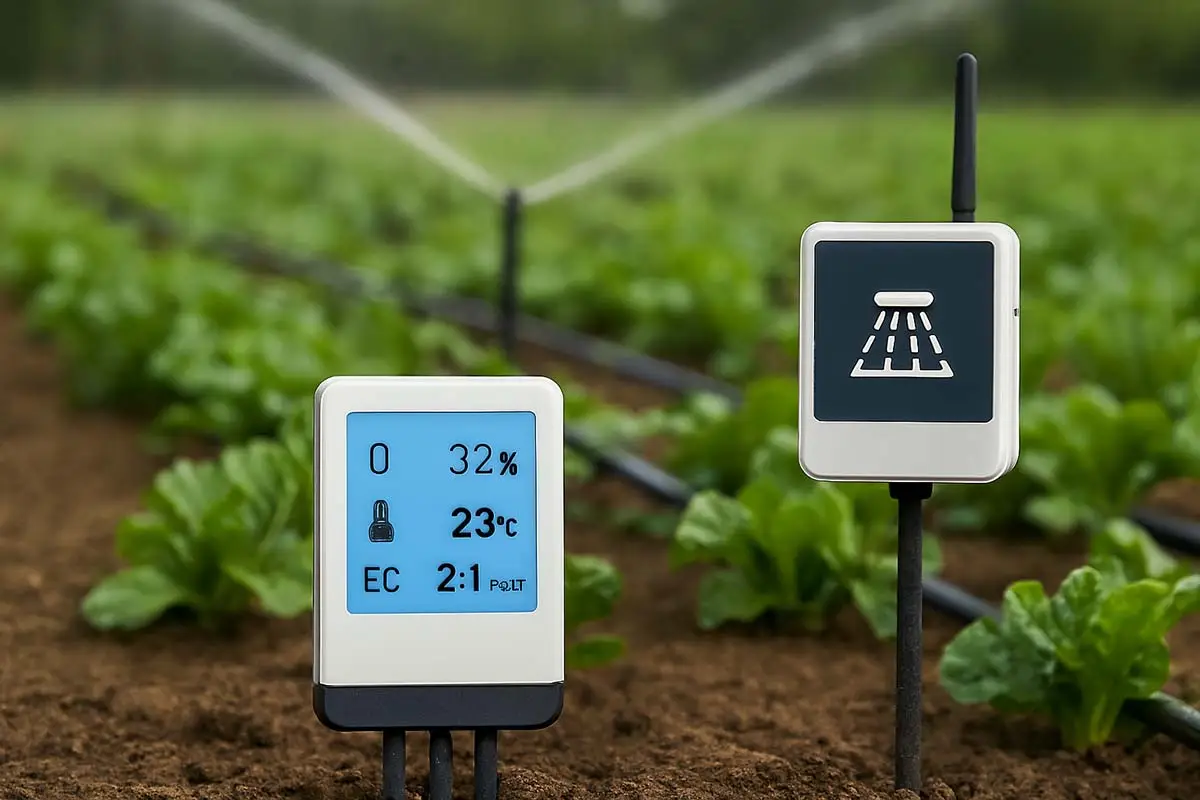

Some advanced farms use hydraulic fluid sensors integrated into equipment to provide real-time alerts on fluid contamination and temperature, enabling predictive maintenance.

Hydraulic Maintenance on Farm Equipment FAQ

Further Read

- Industrial Tools in Agriculture – Powering Farming

- Overview of industrial tools for planting and harvesting

- Small vs Large-Scale Farm Tools: Real-World Case Studies

- Role of Mechanization in Sustainable Agriculture

- Top Agricultural Tool Brands You Should Know

- Emerging trends: automation, AI, and robotics in farming

- Top Industrial Tools Transforming Modern Agriculture

- Essential Maintenance Practices and Tools for Agricultural Machinery: Your Complete Guide

- IoT-Enabled Agricultural Tools

- Drones in agriculture: surveying, planting, and spraying

- Precision farming tools: GPS-guided equipment for planting and harvesting

- Data-driven decision-making in agriculture

- Top 10 Maintenance Tools for Tractors, Harvesters & Irrigation Systems

- Seasonal Maintenance Checklists & Toolkits for Farmers

- Hydraulic System Maintenance Tools for Heavy Farm Equipment

- Lubrication Tools and Best Practices for Agricultural Machinery

- Industrial Torque Wrenches: Key to Farm Equipment Safety

- Best Smart Tightening Tools for Industrial Assembly (2026 Guide)

Conclusion

Maintaining the hydraulic systems of heavy farm equipment is crucial for operational efficiency, safety, and longevity. With the right tools and best practices, farmers can prevent costly failures and keep their machines running at peak performance.

What hydraulic maintenance tools do you rely on? Share your experiences or questions in the comments! And if you found this guide useful, please share it with your network to help fellow farmers maintain their equipment better.