Introduction – Why Industrial Agriculture Tools Matter

In modern agriculture, efficiency is king. Whether you’re planting precision seeds, harvesting tons of grain, or processing crops for market, the right industrial tools can mean the difference between a bumper crop and a missed opportunity. This guide explores essential tools for planting, harvesting, and processing—including what works brilliantly, what’s overrated, and how to choose equipment that fits your needs.

From high-tech planters with GPS guidance to robust combine harvesters, we’ll cover the features, specifications, and practical pros and cons that every grower should know.

1. Industrial Tools for Planting

Planting is more than dropping seeds into the ground—it’s about precision, timing, and uniformity. Modern tools are designed to maximize yield while minimizing waste.

Key Planting Tools

- Precision Planters – Equipped with GPS, variable-rate seeding, and depth control for consistent spacing.

- Seed Drills – Ensures uniform seed distribution, especially for grains.

- Air Seeders – Uses air pressure to distribute seeds evenly across large areas.

- Transplanters – Ideal for vegetables and seedlings; automates transplanting from nursery to field.

Technical Specs to Look For:

| Feature | Why It Matters |

|---|---|

| Row Spacing Adjustability | Adapts to different crops |

| Seed Singulation | Prevents double-seeding |

| Fertilizer Integration | Adds nutrients while planting |

| Control Systems | GPS and software-based precision |

Pro Tip: A poorly calibrated planter can cost 5–10% yield loss—that’s a direct hit to your profits.

2. Industrial Tools for Harvesting

Harvesting tools determine speed, grain quality, and labor costs. Bigger isn’t always better—match machine size to your field and crop type.

Key Harvesting Tools

- Combine Harvesters – All-in-one threshing, separating, and cleaning for grains.

- Forage Harvesters – Cuts and chops crops like corn for silage.

- Mechanical Pickers – Designed for cotton, berries, or specialized crops.

- Nut Harvesters – Shake and collect nuts with minimal damage.

Technical Specs to Look For:

| Feature | Benefit |

|---|---|

| Header Width | Field coverage efficiency |

| Threshing Technology | Reduces grain damage |

| Capacity (tons/hour) | Matches harvest window |

| Fuel Efficiency | Cuts long-term costs |

Reality Check: Even the most advanced harvester can fail if maintenance is neglected—dust, dull blades, and clogged sieves reduce efficiency by up to 20%.

3. Industrial Tools for Processing

Processing transforms raw crops into market-ready products. Industrial tools here are built for speed, hygiene, and consistency.

Key Processing Tools

- Grain Dryers – Reduces moisture to safe storage levels.

- Sorting & Grading Machines – Ensures uniform quality for sale.

- Packaging Lines – Automates bagging, sealing, and labeling.

- Oil Presses & Milling Machines – Adds value by producing edible products.

Technical Specs to Look For:

| Feature | Why It Matters |

|---|---|

| Processing Capacity | Throughput efficiency |

| Automation Level | Reduces labor costs |

| Energy Use | Impacts profitability |

| Maintenance Needs | Downtime reduction |

Interesting Fact:

The largest combine harvester in the world, the Claas Lexion 8900, can harvest up to 100 tons of wheat per hour—that’s about the weight of a fully loaded Boeing 757.

Lesser-Known Fact:

Some high-end planters now use AI-powered soil mapping to adjust seeding rates in real time, based on micro-variations in soil fertility.

4. Pros & Cons of Industrial Agriculture Tools

Pros:

- Massive productivity gains

- Consistent crop quality

- Lower long-term labor costs

- Integration with precision farming software

Cons:

- High initial investment

- Complex maintenance requirements

- Fuel and operational costs

- Risk of over-reliance on technology

5. Buying Tips – How to Choose the Right Tool

- Match the machine to the crop – A cotton picker won’t do well in a wheat field.

- Think total cost of ownership – Factor in fuel, parts, and downtime.

- Prioritize reliability over brand hype – Sometimes the “less famous” models outperform big names in harsh conditions.

- Check resale value – Some models retain 60%+ value after 5 years.

Overview of industrial tools for planting and harvesting FAQ

Conclusion – The Future is Smart and Efficient

Industrial tools for planting, harvesting, and processing are not just equipment—they’re investments in productivity and quality. While high costs and maintenance are real challenges, the benefits in yield, efficiency, and market competitiveness are hard to ignore.

As automation, AI, and robotics advance, expect even more precision, reduced waste, and higher profitability in agriculture.

Further Read

- Industrial Tools in Agriculture – Powering Farming

- Overview of industrial tools for planting and harvesting

- Small vs Large-Scale Farm Tools: Real-World Case Studies

- Role of Mechanization in Sustainable Agriculture

- Top Agricultural Tool Brands You Should Know

- Emerging trends: automation, AI, and robotics in farming

- Top Industrial Tools Transforming Modern Agriculture

- Essential Maintenance Practices and Tools for Agricultural Machinery: Your Complete Guide

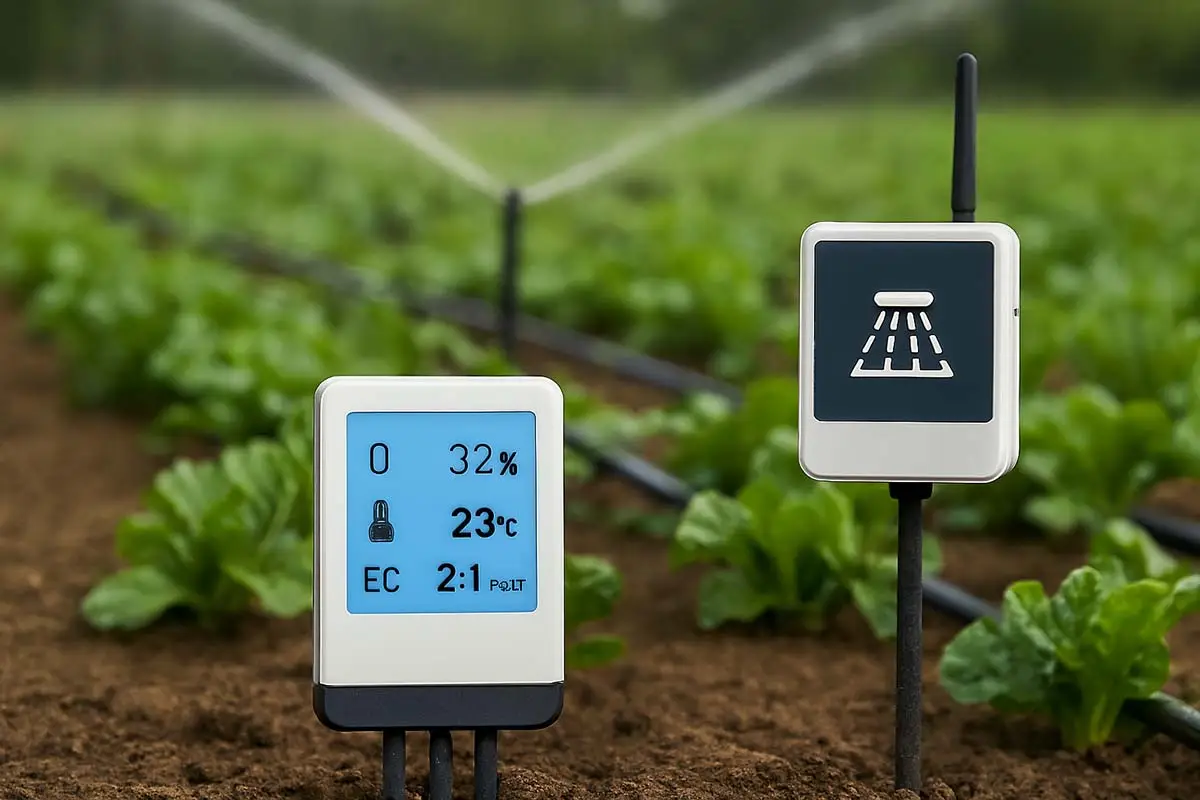

- IoT-Enabled Agricultural Tools

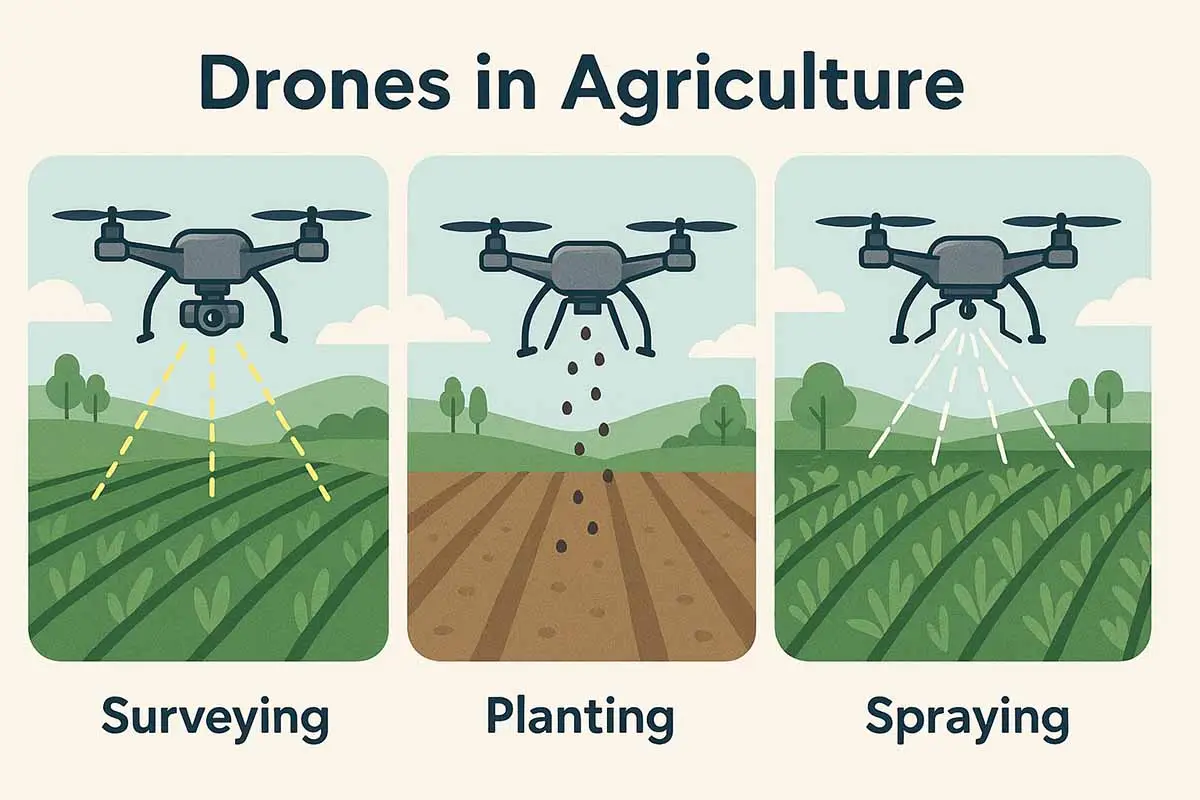

- Drones in agriculture: surveying, planting, and spraying

- Precision farming tools: GPS-guided equipment for planting and harvesting

- Data-driven decision-making in agriculture

- Top 10 Maintenance Tools for Tractors, Harvesters & Irrigation Systems

- Seasonal Maintenance Checklists & Toolkits for Farmers

- Hydraulic System Maintenance Tools for Heavy Farm Equipment

- Lubrication Tools and Best Practices for Agricultural Machinery

- Industrial Torque Wrenches: Key to Farm Equipment Safety

💬 Your Turn: Have you used any of these tools on your farm or in your agribusiness? Share your experiences in the comments, and don’t forget to share this post with your network!