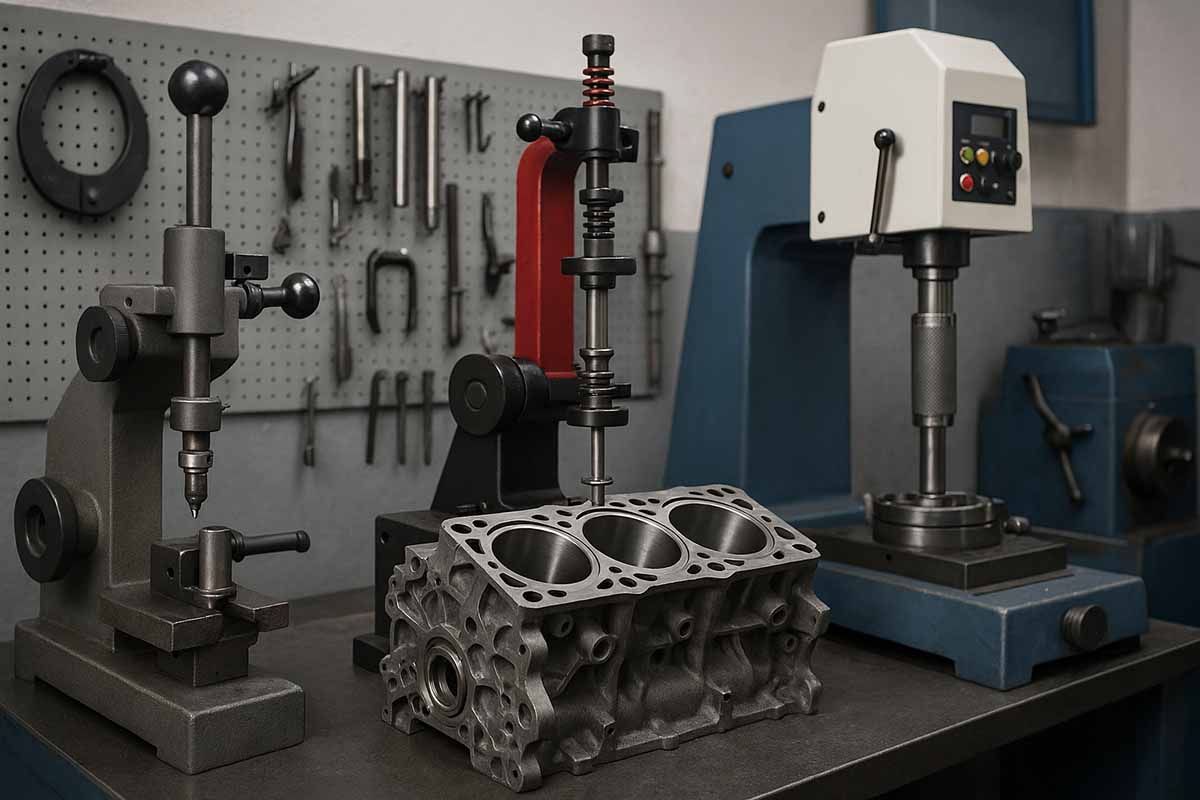

When it comes to engine rebuilding, skill is only half the equation – the other half is having the right specialized equipment. You can be the most talented mechanic in the shop, but if your tools are off by a fraction, your rebuilt engine could be too.

In this guide, we’ll explore the essential, advanced, and often overlooked tools for engine rebuilding, with an honest look at their strengths, weaknesses, and whether they’re worth the investment. We’ll also cover technical specifications, practical examples, and answer common questions enthusiasts and pros ask before starting a rebuild.

Why Specialized Equipment Matters in Engine Rebuilding

Rebuilding an engine isn’t just about replacing worn parts – it’s about precision restoration. A human hair is about 0,0508 milimeters thick. In engine tolerances, that’s huge. Without the right tools, you can’t measure, machine, or assemble parts to spec.

Poorly honed cylinders, misaligned crankshafts, or incorrect torque specs can lead to:

- Reduced power output

- Premature wear

- Oil consumption issues

- Catastrophic failure

The right equipment not only makes the work easier – it makes it possible.

Core Specialized Tools for Engine Rebuilding

1. Engine Stand & Hoist

Purpose: Secure and maneuver the engine for full access.

- Key Features: 360° rotation, high load capacity (1,000–2,000 lbs), heavy-duty locking casters.

- Pro Tip: Choose a stand with adjustable mounting arms for multiple block types.

- Critical Note: Cheap stands can flex under load, causing accuracy issues during assembly.

2. Precision Micrometers & Bore Gauges

Purpose: Measure internal and external dimensions with extreme accuracy.

- Specs to Look For: 0.0001″ resolution, carbide-tipped anvils, digital readout for repeatability.

- Why It Matters: Even a 0.001″ error can throw off compression ratios and bearing clearances.

- Lesser-Known Fact: Temperature can change readings – measure in a climate-stable environment.

3. Cylinder Hone (Rigid or Portable)

Purpose: Refines cylinder surface for piston ring seating.

- Key Types:

- Rigid hone (shop-grade, perfect for consistent finishes)

- Ball hone (hand drill-friendly, good for quick refresh)

- Common Mistake: Over-honing can enlarge bore size beyond spec – measure constantly.

4. Valve Seat & Guide Machines

Purpose: Ensures valves seal perfectly to maintain compression.

- Pro Tip: CNC valve seat machines improve accuracy and speed for high-performance builds.

- Weak Point: Manual seat cutters require experience to avoid uneven sealing surfaces.

5. Crankshaft Grinder & Balancer

Purpose: Restores crankshaft journals and balances rotating assemblies.

- Important Spec: Balancers should handle crankshaft assemblies up to 1,000mm.

- Interesting Fact: Even factory-new crankshafts are not perfectly balanced – race teams always recheck.

6. Torque Wrench (Beam, Click, or Digital)

Purpose: Applies precise tightening force to fasteners.

- Specs: ±2% accuracy, dual scale (Nm and ft-lbs), calibration certificate included.

- Common Overlook: Torque wrench storage matters – always reset to zero after use.

7. Ultrasonic Parts Cleaner

Purpose: Deep-cleans components without abrasive damage.

- Why It’s a Game-Changer: Removes carbon, varnish, and debris from oil passages you can’t reach manually.

Specialty Equipment for Performance & High-Precision Rebuilds

- Plasma Piston Coating Systems – Reduces friction in performance builds.

- Laser Alignment Tools – Checks camshaft and crankshaft alignment without full teardown.

- Digital Profilometers – Measures surface roughness on sealing faces for gasket longevity.

Common Weaknesses in Certain Brands

While many tools look similar, some cheaper imports suffer from:

- Poor calibration (micrometers off by 0.002″ out of the box)

- Low-grade steel in torque wrench ratchets

- Wobble in honing fixtures causing taper in cylinders

Rule of Thumb: If accuracy matters (measuring, machining), invest in high-quality brands. For holding fixtures, mid-tier may suffice.

Interesting & Lesser-Known Facts

- Interesting Fact: In Formula 1, engine rebuilds happen after as little as 1 race, and every tool used is rechecked for calibration.

- Lesser-Known Fact: Some old-school builders still lap valves entirely by hand – and in certain low-RPM engines, it still works just as well as machine cutting.

Specialized Equipment for Engine Rebuilding FAQ

You May Want to Read More About the Automotive Industry

- Industrial Tools in the Automotive Industry

- Digital Twins in Automotive Tooling: Smarter Maintenance, Fewer Breakdowns

- Comparing Pneumatic vs. Electric Tools in Automotive Workshops

- How Industry 4.0 Is Reshaping Automotive Assembly Lines

- Trends in Automotive Manufacturing Automation

- Impact of Industry 4.0 and IoT on Automotive Tooling

- Essential EV Toolkits for Modern Automotive Work

- Reviews of 5 Leading Automotive Tool Brands

- Top Tools for Automotive Repair and Diagnostics

- Specialized Equipment for Engine Rebuilding

- Automotive Fasteners and Torque Specs Explained

- Safety Tools and PPE in Automotive Workshops

- Troubleshooting Common Automotive Tool Problems

- Top Automotive Tool Brands Reviewed

- Fasteners in Automotive Manufacturing: What Makes the Cut?

- How to Use a Torque Wrench in the Automotive Industry

- Automotive Torque Wrench Buying Guide 2025

- Best Smart Tightening Tools for Industrial Assembly (2026 Guide)

Final Thoughts

A successful engine rebuild is the result of skill, patience, and the right specialized equipment. The difference between a rebuild that lasts 200,000 miles and one that fails after 20,000 often comes down to the precision of your tools.

Your turn: Have you had a rebuild succeed – or fail – because of a specific tool? Share your experiences in the comments below, and if you found this guide useful, please share it with fellow mechanics and enthusiasts on social media.