Introduction

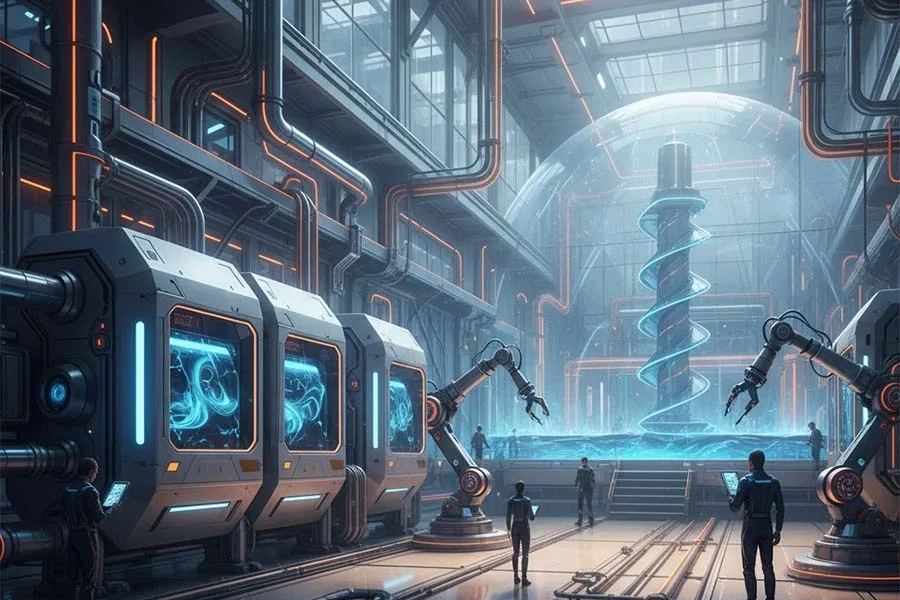

From towering drilling rigs to massive turbines, heavy machinery is the backbone of oil and energy production. These machines don’t just move materials; they move economies. Without them, exploration, drilling, refining, and power generation would grind to a halt. Whether it’s pumping crude from deep underground or turning natural gas into electricity, heavy machinery ensures energy keeps flowing.

In this article, we’ll look at the essential heavy equipment in oil and energy production, explore their roles, benefits, and challenges, and peek into what the future holds.

Why Heavy Machinery Matters in Oil & Energy

The oil and energy industries are high-stakes environments where efficiency, safety, and reliability determine profitability. Heavy machinery enables:

- High-volume operations – moving thousands of tons of materials daily.

- Precision in extreme conditions – deep-sea drilling and desert operations demand robust machines.

- Safety – mechanized lifting and transport reduce human exposure to hazards.

- Sustainability – modern machines are increasingly energy-efficient, lowering environmental impact.

Key Heavy Machinery in Oil and Energy Production

1. Drilling Rigs

The symbol of oil exploration, drilling rigs (both land-based and offshore) are engineering marvels. They handle extreme loads, use automated pipe handling, and now often integrate digital drilling controls.

2. Excavators and Loaders

Onshore sites and pipeline projects depend on excavators, bulldozers, and loaders for earthmoving, trenching, and site preparation. These machines can operate in tough terrains from Arctic tundras to Middle Eastern deserts.

3. Cranes and Hoisting Systems

Massive cranes are used to lift heavy modules on offshore platforms and refineries. Some floating cranes can handle loads exceeding 10,000 tons – that’s heavier than the Eiffel Tower!

4. Pumps and Compressors

Not always visible, but absolutely vital: pumps keep oil flowing through pipelines, while compressors push natural gas over vast distances. High-pressure, high-capacity systems are designed to run continuously with minimal downtime.

5. Turbines and Generators

In power plants, gas and steam turbines convert fuel into electricity. These machines weigh hundreds of tons and require precise alignment to operate efficiently.

6. Subsea Machinery

Underwater robots, trenching machines, and heavy-duty ROVs (Remotely Operated Vehicles) work at depths of 3,000 meters or more, installing and maintaining subsea infrastructure.

The Role of Digital Integration

Today’s heavy machinery is not just about brute force – it’s about smart force. Many machines now include:

- IoT sensors to monitor wear and performance.

- Automated systems for improved accuracy and safety.

- AI analytics for predictive maintenance.

- Remote operation controls to reduce on-site workforce risk.

Challenges in Heavy Machinery Use

Even with modern advances, challenges remain:

- Maintenance costs – repairs and downtime can cost millions per day.

- Transportation logistics – moving oversized machinery is a project in itself.

- Environmental regulations – emissions and noise limits require constant innovation.

- Skill shortages – trained operators and technicians are in high demand.

Future Outlook

The future of heavy machinery in oil and energy will likely see:

- More automation – self-driving excavators and remotely operated cranes.

- Greener power sources – hybrid and electric heavy equipment.

- Advanced materials – lighter, stronger alloys to improve efficiency.

- Digital twins – virtual replicas of heavy machinery to optimize performance and predict failures.

Funny Fact

The largest crane in the world, used in energy projects, can lift 20,000 tons – that’s about the weight of 2 Eiffel Towers stacked on top of each other. Now that’s what you call a heavyweight champion!

Lesser-Known Fact

The first offshore drilling rigs in the 1940s were built using modified land-based equipment placed on barges. It took decades of engineering innovation to create the purpose-built offshore machinery we see today.

Further Reading

- Industrial Tools in the Energy and Oil Industry

- Drilling and Extraction Tools in the Oil Industry: Complete Guide 2025

- Maintenance Tools for Oil Refineries: Complete Guide to Essential Equipment

- Pipeline Construction and Repair Tools | Essential Guide for Oil & Energy

- Safety Tools and Equipment in the Energy Sector

- Automation and Digital Tools in Oil & Gas

- Heavy Machinery in Oil and Energy Production

- Inspection and Testing Tools in Oil & Gas

- Tool Innovations Shaping the Future of Oil and Energy

Conclusion

Heavy machinery is the muscle behind oil and energy production. Without it, exploration, extraction, and power generation would be impossible. With automation, AI, and sustainable designs, these machines are evolving to meet the demands of a changing energy landscape.

What do you think – will heavy machinery in oil and energy ever become fully autonomous, or will humans always need to be in the operator’s seat? Share your thoughts in the comments below!