Introduction

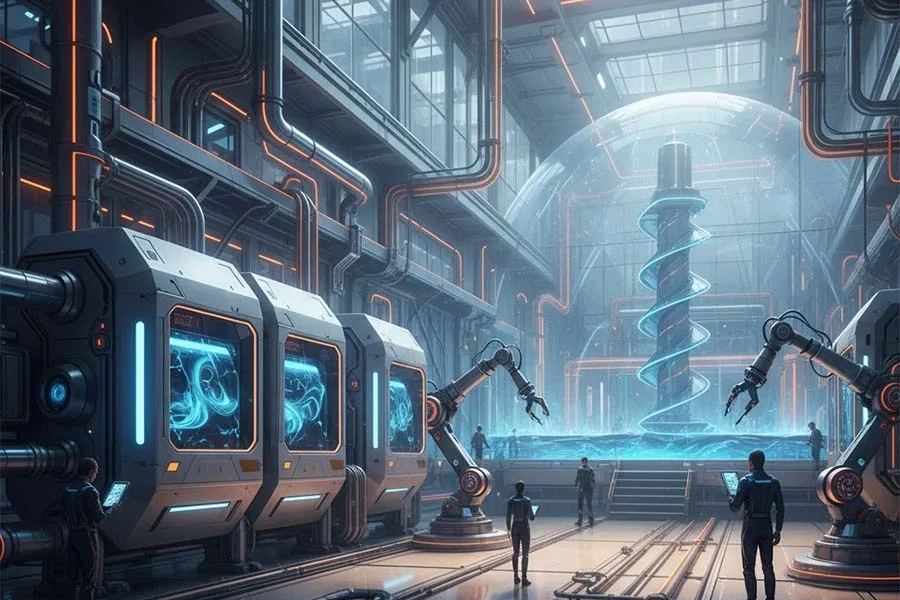

Pipelines are the lifelines of the oil and energy industry. They transport crude oil, natural gas, and refined products over vast distances, often under extreme conditions. Building and maintaining these pipelines requires a specialized set of tools designed for precision, durability, and safety. Without them, even a minor failure could lead to catastrophic consequences – from environmental disasters to costly shutdowns.

In this article, we’ll dive deep into the pipeline construction and repair tools that keep the energy sector running smoothly, covering everything from welding machines to smart inspection devices.

Why Are Pipeline Tools So Critical?

Pipelines operate under high pressures and must meet strict regulatory standards. Tools ensure:

- Precision – achieving exact welds, bends, and joints.

- Durability – withstanding corrosive environments and heavy usage.

- Safety – reducing the risk of leaks, explosions, and accidents.

- Efficiency – minimizing downtime during construction and repair.

Core Tools for Pipeline Construction

1. Pipe Cutting and Beveling Machines

- Create precise cuts and angles for welding.

- Portable and available in manual, electric, and hydraulic versions.

- Common in both onshore and offshore pipeline projects.

2. Pipe Bending Tools

- Hydraulic and CNC pipe benders ensure proper alignment.

- Prevents stress fractures and guarantees smooth flow.

- Essential in rugged terrain and complex layouts.

3. Welding Equipment

- Automatic welding machines dominate long-distance pipeline construction.

- Ensure consistent, high-quality welds at faster speeds.

- Hot-tap welding tools allow repairs without shutting down the line.

4. Alignment Clamps

- Keep pipes perfectly aligned during welding.

- Available in internal and external models.

- Reduce welding defects and rework costs.

Key Tools for Pipeline Maintenance and Repair

1. Pipeline Inspection Gauges (PIGs)

- Travel inside pipelines to clean, measure, and detect defects.

- Smart PIGs use sensors for corrosion, cracks, and metal loss detection.

- Crucial for preventive maintenance.

2. Ultrasonic Testing Devices

- Identify wall thickness and hidden cracks.

- Portable, non-destructive, and accurate.

3. Leak Detection Tools

- Acoustic sensors, pressure monitors, and drones equipped with infrared cameras.

- Provide early warnings before leaks escalate.

4. Coating and Wrapping Tools

- Apply protective layers to prevent corrosion.

- Wrapping machines streamline large-scale protective coating work.

5. Grinding and Polishing Tools

- Smooth out welds, remove defects, and prep surfaces.

- Essential before re-coating or inspections.

Safety Equipment for Pipeline Work

Pipeline construction and maintenance demand strict safety measures. Essential safety tools include:

- Gas detectors for toxic or explosive gases.

- Explosion-proof lighting in hazardous zones.

- Personal protective equipment (PPE): helmets, flame-resistant clothing, gloves.

Future of Pipeline Tools: Digital and Automated Solutions

The future is moving toward:

- Robotics – remote-controlled welding and inspection robots.

- Drones – for aerial inspection in inaccessible areas.

- IoT integration – sensors for real-time monitoring of pressure and corrosion.

Funny Fact

Pipeline “pigs” don’t squeal, but they do “grunt” when traveling inside pipes – early models got their name from the squeaky sounds they made.

Lesser-Known Fact

Some modern smart PIGs can create a full 3D map of the pipeline interior, allowing engineers to spot defects within millimeters of accuracy, even in pipelines that stretch hundreds of kilometers.

Further Reading

- Industrial Tools in the Energy and Oil Industry

- Drilling and Extraction Tools in the Oil Industry: Complete Guide 2025

- Maintenance Tools for Oil Refineries: Complete Guide to Essential Equipment

- Pipeline Construction and Repair Tools | Essential Guide for Oil & Energy

- Safety Tools and Equipment in the Energy Sector

- Automation and Digital Tools in Oil & Gas

- Heavy Machinery in Oil and Energy Production

- Inspection and Testing Tools in Oil & Gas

- Tool Innovations Shaping the Future of Oil and Energy

Conclusion

Pipeline construction and repair tools are the backbone of the oil and energy industry. From welding machines and alignment clamps to smart PIGs and ultrasonic testers, each tool plays a vital role in ensuring safe, efficient, and long-lasting pipelines. With technology advancing rapidly, digital and automated solutions are set to reshape the future of pipeline maintenance, making it safer and more efficient than ever before.