Introduction

The oil and energy sector is no stranger to technology. From the first steam-powered rigs to today’s AI-driven operations, innovation has always been the industry’s engine. But now, with digital transformation, automation, and sustainability pressures, tool innovation is moving faster than ever. The tools shaping the future of oil and energy are smarter, cleaner, and more connected—paving the way for safer, more efficient, and more sustainable operations.

In this article, we’ll explore the key tool innovations driving the industry forward and how they’re changing the way oil and energy companies operate.

Why Innovation Matters

Global energy demand is rising, while environmental regulations are tightening. The industry faces the dual challenge of meeting demand while reducing its footprint. Tool innovations help by:

- Boosting efficiency – reducing waste and downtime.

- Enhancing safety – minimizing human exposure to dangerous environments.

- Enabling sustainability – lowering emissions and improving monitoring.

- Future-proofing operations – preparing companies for the next wave of digitalization.

Key Tool Innovations in Oil & Energy

1. Smart Drilling Tools

Modern drilling tools now feature real-time downhole sensors that transmit data on pressure, temperature, and rock formation. These “smart bits” help optimize drilling paths, reduce wear, and cut operational costs.

2. AI-Powered Predictive Maintenance

AI-driven tools analyze vibration, temperature, and performance data to predict failures before they happen. This not only saves money but also prevents catastrophic breakdowns.

3. Digital Twin Technology

Digital twins—virtual replicas of equipment, rigs, or even entire plants—allow operators to test scenarios without risking real-world downtime. They’re being paired with augmented reality (AR) tools for immersive training and maintenance guidance.

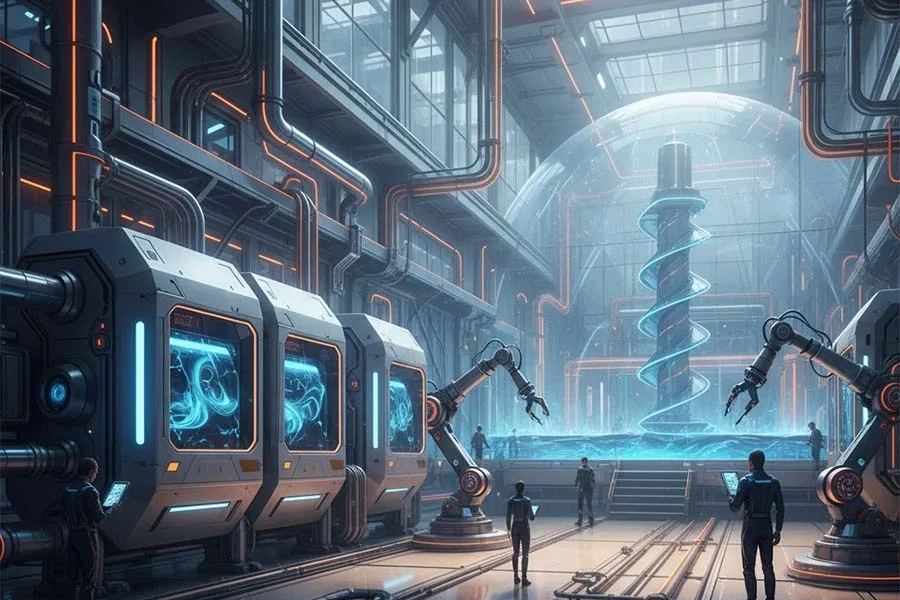

4. Robotics and Autonomous Systems

From robotic pipe handlers to autonomous subsea inspection drones, robotics are reducing the need for human intervention in hazardous areas. Future tools may include fully autonomous rigs operating with minimal crews.

5. IoT-Enabled Sensors

Tiny yet powerful, IoT sensors are being embedded in pipelines, valves, and heavy machinery. They provide real-time monitoring of corrosion, leaks, and performance—turning traditional assets into smart, connected systems.

6. Green Innovations

Sustainability-focused tools are also emerging, including:

- Carbon capture monitoring devices.

- Emission detection sensors that can identify methane leaks instantly.

- Hybrid and electric machinery for reduced environmental impact.

Challenges to Adoption

Despite their promise, these innovations face barriers:

- High costs of implementation.

- Cybersecurity risks with connected tools.

- Skill gaps—technicians must be trained to use advanced digital systems.

- Integration issues with legacy infrastructure.

Future Outlook

The future of oil and energy tools will be defined by automation, connectivity, and sustainability. In the next decade, expect to see:

- Widespread self-healing materials for pipelines and equipment.

- Fully autonomous inspection drones operating in extreme conditions.

- Greater adoption of AI-driven decision-making tools.

- Tools designed specifically to support renewable integration into traditional energy grids.

Funny Fact

In some pilot projects, oil companies are experimenting with VR headsets for virtual rig inspections. Imagine inspecting a refinery while sitting at home in your pajamas—talk about “remote work”!

Lesser-Known Fact

The concept of digital twin technology actually originated from NASA’s Apollo missions, where engineers created physical and digital replicas of spacecraft systems to solve problems in real time. Today, the same idea helps oil and energy companies run safer and smarter.

Further Reading

- Industrial Tools in the Energy and Oil Industry

- Drilling and Extraction Tools in the Oil Industry: Complete Guide 2025

- Maintenance Tools for Oil Refineries: Complete Guide to Essential Equipment

- Pipeline Construction and Repair Tools | Essential Guide for Oil & Energy

- Safety Tools and Equipment in the Energy Sector

- Automation and Digital Tools in Oil & Gas

- Heavy Machinery in Oil and Energy Production

- Inspection and Testing Tools in Oil & Gas

- Tool Innovations Shaping the Future of Oil and Energy

Conclusion

Tool innovations are reshaping oil and energy production, making operations safer, smarter, and more sustainable. From smart drilling systems to AI-driven maintenance and IoT monitoring, these technologies are setting the stage for the industry’s future.

Do you think the oil and energy sector will one day be run almost entirely by autonomous tools, or will human expertise always remain essential? Share your thoughts in the comments below!