Why Data Matters in Industry 4.0

Industry 4.0 thrives on data. Every connected machine, sensor, and device continuously generates information about performance, energy use, quality, and more. On its own, this raw data is overwhelming – but with the right processing and analysis, it becomes the most valuable asset in modern manufacturing. Data is the fuel that powers predictive maintenance, supply chain visibility, and real-time optimization.

The Role of Cloud Computing

Cloud computing is the backbone of data-driven manufacturing. Instead of relying on limited on-premise servers, organizations can tap into cloud platforms that scale with their needs. The benefits are clear:

- Scalability: Handle terabytes or even petabytes of data without physical limitations.

- Accessibility: Teams across the globe can securely access the same information in real time.

- Integration: Cloud platforms connect seamlessly with IIoT devices, digital twins, and AI systems.

For manufacturers, the cloud doesn’t just reduce infrastructure costs – it accelerates innovation by making industrial data available anytime, anywhere.

The Power of Data Analytics

Data analytics is what transforms numbers into knowledge. In Industry 4.0, analytics goes beyond traditional reports:

- Descriptive analytics tells you what has happened.

- Predictive analytics forecasts what is likely to happen.

- Prescriptive analytics recommends the best course of action.

When applied to manufacturing, analytics enables everything from real-time quality control to predictive maintenance. It helps managers identify inefficiencies, reduce downtime, and make faster, more confident decisions.

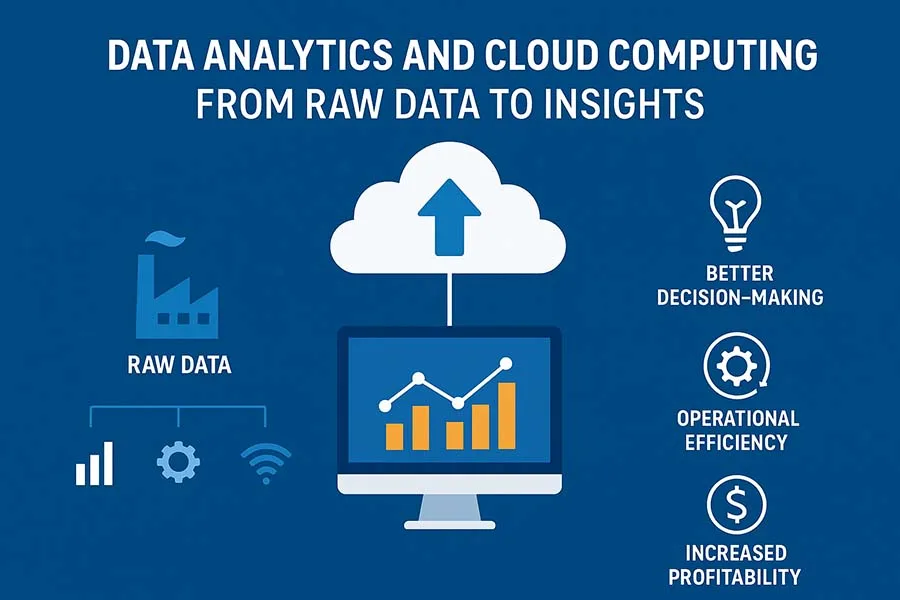

Cloud + Analytics = Smarter Manufacturing

The true value emerges when cloud computing and analytics work together. Cloud platforms gather and process massive volumes of industrial data, while analytics engines mine that data for actionable insights. Together, they provide:

- Real-time dashboards for operators on the shop floor.

- Predictive models that prevent breakdowns before they occur.

- Supply chain intelligence that improves forecasting and reduces bottlenecks.

- Sustainability insights that track energy use and carbon footprint.

This synergy creates a continuous loop: collect → analyze → act → improve.

Real-World Applications

- Predictive Maintenance: Sensors send machine data to the cloud, analytics predicts failures, and maintenance is scheduled before costly breakdowns.

- Quality Control: AI-driven analytics detects product defects in real time, reducing waste.

- Smart Supply Chains: Cloud-based visibility ensures that disruptions are spotted and mitigated early.

- Energy Optimization: Analytics highlight inefficiencies in energy usage, cutting costs and emissions.

Challenges and Considerations

While powerful, adopting data analytics and cloud computing comes with challenges:

- Data security and privacy must be carefully managed.

- Integration complexity with legacy systems can slow implementation.

- Skill gaps in data science and cloud technologies may require training or hiring.

However, companies that address these challenges unlock a competitive edge that is hard to match.

Looking Ahead

As cloud computing becomes more affordable and analytics more advanced, the combination will continue to reshape industry. Edge computing – processing data closer to where it’s generated – will further complement the cloud, reducing latency and enabling even faster decision-making.

In Industry 4.0, success isn’t just about collecting data – it’s about making sense of it. Cloud computing and data analytics ensure that raw information doesn’t stay trapped in silos but becomes the driver of smarter, faster, and more sustainable manufacturing.

Further Read

- Core Foundations of Industry 4.0: The Tech Stack Explained

- Industrial Internet of Things (IIoT): Connecting Machines, Data, and People

- Digital Twin Technology: From Concept to Real-World Applications

- Robotics and Automation: The Heart of Smart Manufacturing

- Artificial Intelligence (AI) and Machine Learning: Smarter Manufacturing

- Augmented Reality (AR) and Virtual Reality (VR): The Human-Tech Interface

- Data Analytics and Cloud Computing in Industry 4.0

- Cybersecurity in Industry 4.0: Protecting the Smart Factory

- Integration and Interoperability in Industry 4.0

- Benefits of Understanding the Core Foundations: People, Processes, and Technology

- Challenges and Barriers in Industry 4.0: Overcoming the Roadblocks to Smart Manufacturing

- The Future of Manufacturing: Towards Industry 5.0