Introduction

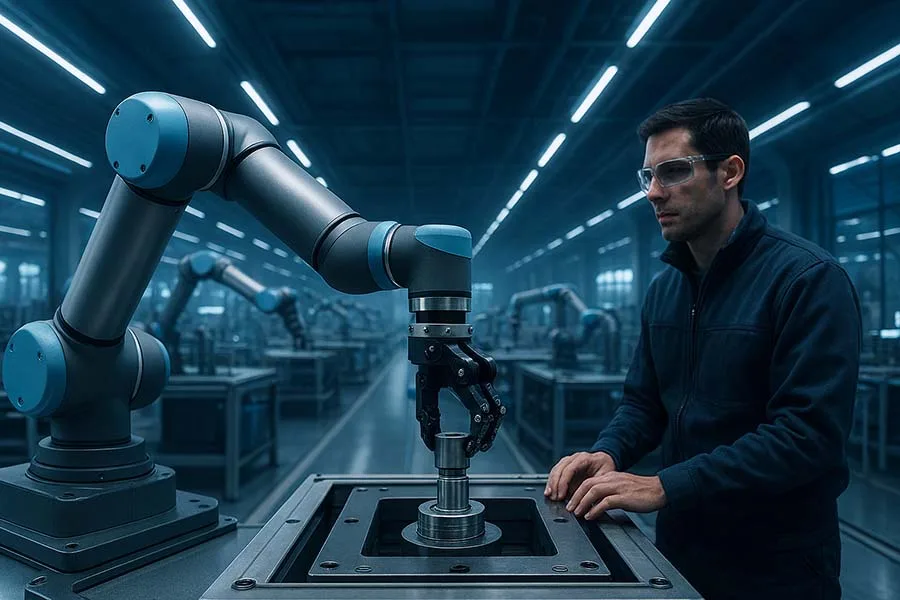

In the ever-evolving landscape of industrial automation, collaborative robots (cobots) have emerged as game-changers. Unlike traditional industrial robots that operate in isolation, cobots are designed to work alongside human operators, enhancing productivity, safety, and flexibility on the factory floor.

What Are Cobots?

Collaborative robots, or cobots, are robotic systems engineered to safely interact and collaborate with human workers in a shared workspace. They are equipped with advanced sensors, force-limiting technology, and intuitive programming interfaces, enabling them to perform tasks such as assembly, welding, packaging, and inspection alongside humans without the need for safety cages.

Key Differences Between Cobots and Traditional Robots

| Feature | Cobots | Traditional Robots |

|---|---|---|

| Human Interaction | Designed to work alongside humans | Operate independently or in isolated cells |

| Safety Features | Built-in sensors and force-limiting tech | Require external safety barriers |

| Flexibility | Easily reprogrammable for various tasks | Typically programmed for specific tasks |

| Cost | Lower initial investment and maintenance | Higher upfront costs and maintenance |

| ROI | Often achieves ROI within 1 year | Longer ROI periods |

Safety Features: Ensuring a Secure Work Environment

Cobots are equipped with various safety features to ensure a secure working environment:

- Force Limiting: Cobots can detect and respond to contact with humans, reducing the risk of injury.

- Advanced Sensors: These sensors allow cobots to navigate and adapt to their surroundings, avoiding obstacles and ensuring safe operation.

- Compliance with Standards: Cobots adhere to international safety standards, such as ISO/TS 15066, ensuring they meet rigorous safety requirements.

Flexibility: Adapting to Changing Production Needs

Cobots offer unparalleled flexibility in manufacturing:

- Quick Reprogramming: Operators can easily reprogram cobots to perform different tasks, reducing downtime and increasing efficiency.

- Adaptability: Cobots can be integrated into various production lines, from small-batch to high-volume manufacturing, accommodating diverse production needs.

- Scalability: As production demands grow, additional cobots can be added to the system without significant infrastructure changes.

Return on Investment (ROI): A Smart Business Decision

Investing in cobots offers substantial financial benefits:

- Quick Payback Period: Many companies experience a return on investment within one to two years due to increased productivity and reduced labor costs.

- Cost Savings: Cobots have lower upfront costs and maintenance expenses compared to traditional robots, making them accessible to small and medium-sized enterprises.

- Increased Productivity: By automating repetitive tasks, cobots free up human workers to focus on more complex and value-added activities, enhancing overall productivity.

Real-World Applications: Cobots in Action

Cobots are being utilized across various industries:

- Automotive Manufacturing: Cobots assist in assembly, welding, and quality inspection, improving efficiency and precision.

- Electronics Assembly: Cobots handle delicate components, reducing the risk of damage and enhancing product quality.

- Food Packaging: Cobots automate packaging processes, ensuring consistency and hygiene in food production.

Source: Manufacturing Tomorrow

Lesser-Known Facts About Cobots

- First Cobot Handshake: The first human-robot handshake was achieved by a cobot, symbolizing the harmonious collaboration between humans and machines.

- Cobot in Space: Cobots have been used in space missions, assisting astronauts with tasks and demonstrating their versatility beyond Earth.

Collaborative Robots (Cobots) FAQ

Read more about Robotics & Intelligent Automation in Industry

- Robotics & Intelligent Automation in Industry

- Collaborative Robots (Cobots)

- AI & Machine Vision: How Smart Robots See, Think, and Adapt

- Precision Engineering Meets Robotics

- The Economics of Robotics: Cost, ROI, and When to Automate

- Robotics Safety Standards Every Manufacturer Should Know

- Humans and Robots: The Reality of Shop Floor Collaboration

- Mobile Robotics and AGVs: The Silent Workforce of Logistics

- Robotics in Small and Medium Manufacturing

- The Future of Industrial Tools in a Robotic World

- Disruptive Trends: AI, 5G, and Digital Twins in Robotics

Conclusion

Collaborative robots are transforming the manufacturing landscape by enhancing safety, flexibility, and return on investment. Their ability to work alongside human operators, perform a variety of tasks, and adapt to changing production needs makes them invaluable assets in modern factories. As industries continue to embrace automation, cobots are poised to play a pivotal role in shaping the future of manufacturing.

If you find our content helpful, please consider leaving us a quick Trustpilot review — it means a lot!

We’d love to hear about your experiences with cobots. Share your thoughts in the comments below and don’t forget to share this article on social media!