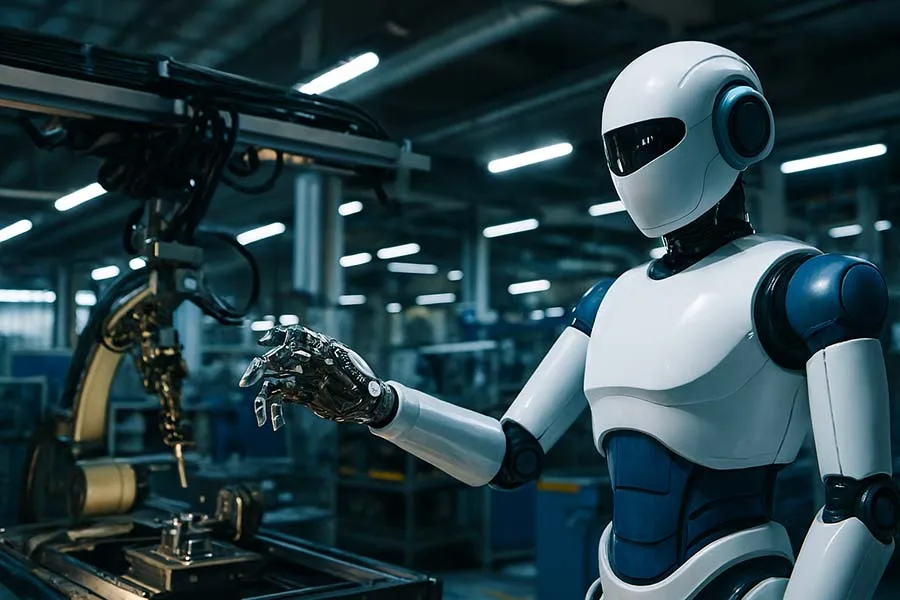

Factories today are not about humans versus machines—they’re about humans with machines. On the modern shop floor, the rise of collaborative robots (cobots) has shifted the conversation from replacement to partnership. Whether in a global automotive plant or a small manufacturing workshop, robots now stand shoulder-to-shoulder with people, taking on repetitive, heavy, and hazardous tasks, while humans focus on supervision, creativity, and complex decision-making.

This article dives deep into the reality of human-robot collaboration, exploring the benefits, challenges, technical details, and future of this growing trend.

What Does Human-Robot Collaboration Really Mean?

In industrial settings, robots traditionally worked inside cages—fast, powerful, and isolated for safety reasons. Collaborative robots (cobots), however, are designed to share the workspace directly with people.

Human-robot collaboration happens at several levels:

- Coexistence: Robots and humans work side by side but on separate tasks.

- Sequential Collaboration: Humans and robots alternate in steps of the same task.

- Simultaneous Collaboration: Robots and humans handle tasks together in the same area.

- Physical Collaboration: Direct human-robot interaction (e.g., hand-guiding a cobot).

The big difference? Safety and adaptability. Cobots are equipped with force sensors, vision systems, and AI-driven controls that allow them to stop instantly if they sense human contact.

Benefits of Working Together on the Shop Floor

The promise of human-robot collaboration is clear. Here are the top benefits:

- Productivity Boosts: Robots don’t tire, and humans excel at problem-solving. Together, they optimize efficiency. A Deloitte study showed that cobots can improve productivity by up to 30% in certain assembly lines.

- Ergonomics and Safety: Repetitive, heavy, and dangerous jobs are delegated to robots, reducing injuries and worker fatigue.

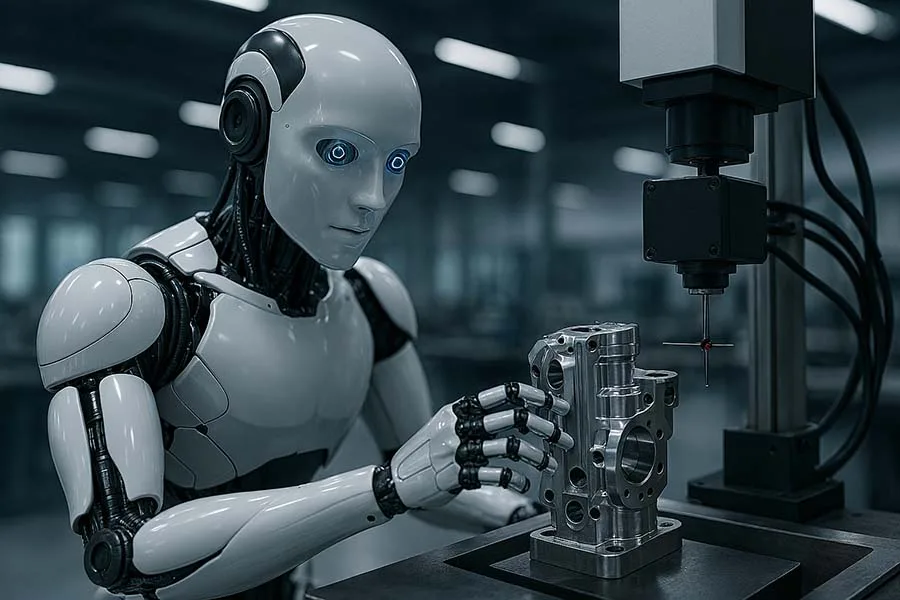

- Consistency and Precision: Robots offer repeatability at ±0.02 mm accuracy, while humans bring judgment and flexibility.

- Worker Satisfaction: Ironically, robots can make work more human by freeing people from dull and dangerous tasks.

💡 Funny Fact: Many factories report that employees nickname their cobots—calling them things like Bob the Robot or Rosie—which makes them feel like colleagues rather than machines.

Challenges and Reality Check

Of course, collaboration isn’t without its hurdles.

- Cost and ROI: A typical cobot setup can cost between $30,000–$50,000, with ROI timelines ranging from 6 months to 3 years, depending on application.

- Training Needs: Workers need to learn how to program and maintain cobots. Thankfully, modern cobots are designed with simple drag-and-drop programming.

- Acceptance and Trust: Some employees worry about job security or feel uneasy around robots.

- Downtime Risks: Robots don’t get sick, but they do need maintenance. A sensor failure can stop production.

In reality, the success of human-robot teams depends on change management and proper integration, not just buying the latest tech.

Human vs. Robot Strengths – Side by Side

| Feature | Humans | Robots (Cobots) |

|---|---|---|

| Strength/Endurance | Limited, fatigue over time | Can lift heavy loads continuously |

| Precision | High, but inconsistent over time | Extremely consistent, micrometer-precise |

| Adaptability | Very high, can switch tasks quickly | Limited to programmed tasks |

| Creativity & Problem-Solving | Excellent | Minimal, unless AI-driven |

| Safety Awareness | Natural instincts | Sensor-based detection |

| Training Time | Years of experience | Hours to days (intuitive programming) |

The table shows why collaboration makes sense: humans adapt, robots execute.

Real-World Examples of Shop Floor Collaboration

- Automotive Industry: BMW uses cobots to apply adhesives inside car body frames, reducing strain on workers. Audi employs cobots in precision assembly tasks.

- Tesla Factories: Tesla combines high-speed industrial robots with human oversight, proving that flexibility still requires human involvement.

- Small and Medium Enterprises (SMEs): Universal Robots (UR) cobots are popular among SMEs due to their plug-and-play setup and affordable cost. A bakery in Europe even uses cobots to decorate cakes—an example of precision and creativity blending.

📈 Market Data: The global cobot market is projected to grow at a 22% CAGR through 2030, reflecting the rising demand for human-robot teamwork.

Key Technical Features of Collaborative Robots

Cobots differ from traditional robots in technical design. Here are the highlights:

- Safety Systems: Force/torque sensors, vision cameras, and speed limits.

- Ease of Programming: Hand-guiding (moving the arm manually to teach motions) and touchscreen drag-and-drop interfaces.

- Flexibility: Quick re-deployment between tasks.

- Compact Size: Designed to fit small shop floors without cages.

Example Cobot Specifications

| Model | Payload Capacity | Reach | Repeatability | Programming Style |

| UR10e (Universal Robots) | 12.5 kg | 1300 mm | ±0.05 mm | Hand-guiding, tablet-based |

| KUKA LBR iiwa | 14 kg | 820 mm | ±0.1 mm | Force-sensitive, intuitive |

| FANUC CRX-10iA | 10 kg | 1249 mm | ±0.03 mm | Drag-and-drop, safe stop |

Future of Human-Robot Shop Floor Collaboration

The future points to smarter, more adaptable robots that learn alongside humans:

- AI-powered vision systems will allow robots to adapt on the fly.

- Humans will transition into supervisory, analytical, and creative roles.

- By 2035, hybrid teams (human + robot) are expected to dominate manufacturing, blending speed, flexibility, and intelligence.

💡 Lesser-Known Fact: Some research labs are developing emotionally aware robots that can detect human stress levels through voice and posture—potentially adjusting their speed or behavior accordingly.

Read more about Robotics & Intelligent Automation in Industry

- Robotics & Intelligent Automation in Industry

- Collaborative Robots (Cobots)

- AI & Machine Vision: How Smart Robots See, Think, and Adapt

- Precision Engineering Meets Robotics

- The Economics of Robotics: Cost, ROI, and When to Automate

- Robotics Safety Standards Every Manufacturer Should Know

- Humans and Robots: The Reality of Shop Floor Collaboration

- Mobile Robotics and AGVs: The Silent Workforce of Logistics

- Robotics in Small and Medium Manufacturing

- The Future of Industrial Tools in a Robotic World

- Disruptive Trends: AI, 5G, and Digital Twins in Robotics

Conclusion

Human-robot collaboration is not science fiction—it’s the reality of today’s shop floor. Robots aren’t replacing workers; they’re empowering them, reducing strain, and improving efficiency. As cobots get smarter and more affordable, the future belongs to factories where humans and robots work better together.

👉 What do you think? Would you trust a cobot to work right next to you? Share your thoughts in the comments and let’s discuss how collaboration is shaping the future of manufacturing.