Introduction

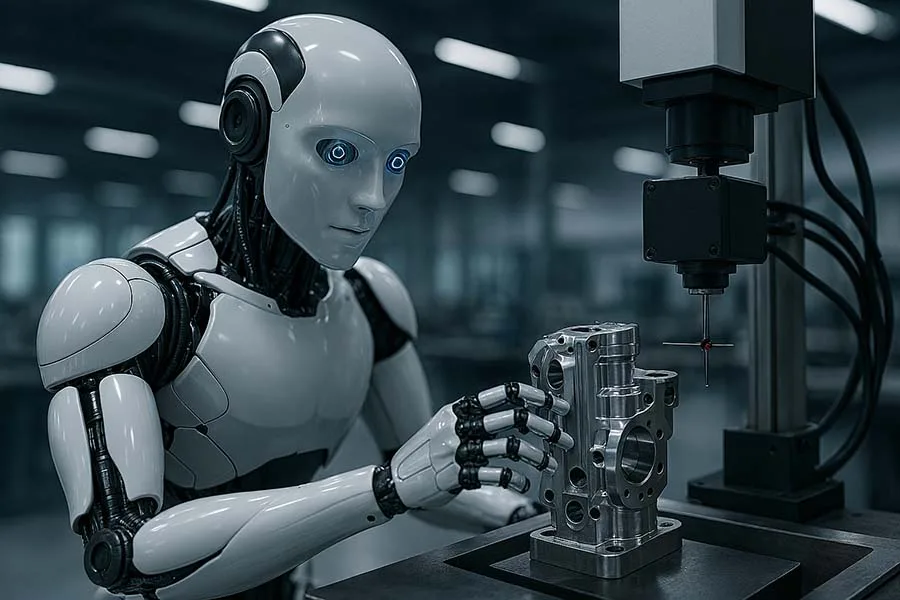

In the era of Industry 4.0, robots are no longer just mechanical arms executing repetitive tasks—they are intelligent systems that can see, think, and adapt. Powered by AI and machine vision, these smart robots are transforming manufacturing, logistics, and quality control. By combining visual perception with advanced algorithms, robots can analyze environments in real time, make decisions, and optimize workflows with remarkable precision.

What Is Machine Vision in Robotics?

Machine vision is the technology that allows robots to capture and process visual information, similar to how humans see. When integrated with artificial intelligence (AI), machine vision enables robots to:

- Recognize objects, shapes, and patterns

- Detect defects or inconsistencies in products

- Track and follow moving objects

- Make adaptive decisions based on visual input

Unlike traditional automation, which relies on fixed instructions, AI-powered robots can learn and improve from their visual observations.

How AI Enhances Machine Vision

AI algorithms, including deep learning and neural networks, allow machines to interpret complex visual data. Key advantages include:

- Accuracy: AI can detect subtle defects in manufacturing far beyond human capability.

- Speed: Smart robots can analyze visual data in milliseconds, boosting throughput.

- Adaptability: They can adjust operations in real time if conditions change, reducing downtime.

- Predictive Insights: By analyzing trends in visual data, robots can forecast maintenance needs or process optimizations.

Interesting Fact: Some AI vision systems can identify over 100,000 objects in a single production line image, surpassing human visual recognition in both speed and accuracy.

Applications of AI + Machine Vision

- Quality Inspection: Detecting defects, scratches, or misalignments in high-speed production lines.

- Sorting & Packaging: Recognizing products and sorting them accurately by size, color, or shape.

- Autonomous Navigation: Robots in warehouses or factories navigate complex environments safely.

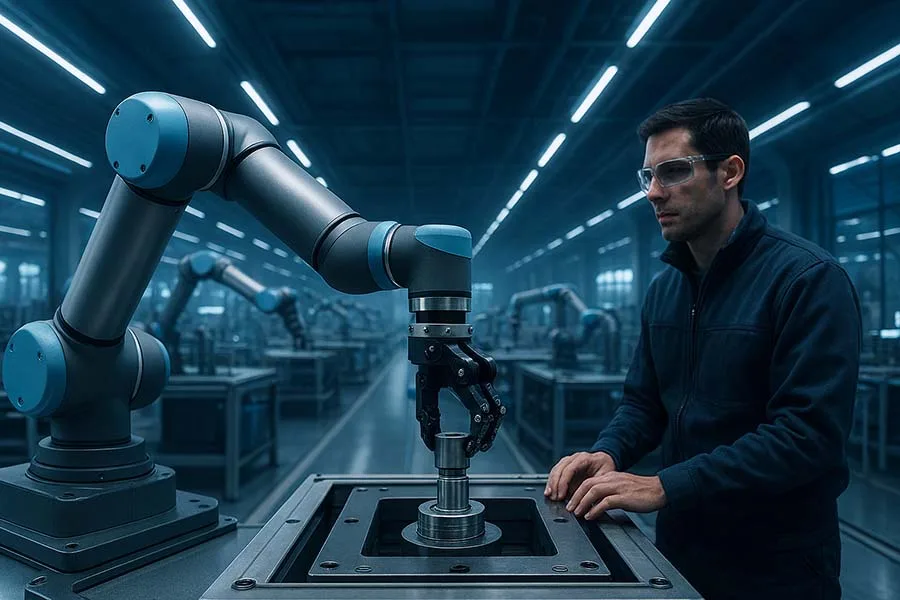

- Collaborative Assembly: AI vision helps cobots identify components and assist human workers.

- Predictive Maintenance: Monitoring machinery visually to detect wear, corrosion, or misalignment before failure.

Lesser-Known Fact: Some smart robots use thermal and infrared imaging combined with AI to detect hidden defects invisible to the naked eye.

Benefits and ROI

Investing in AI-powered machine vision delivers measurable business benefits:

- Reduced Waste: Early defect detection minimizes defective products.

- Increased Efficiency: Robots operate continuously with minimal supervision.

- Enhanced Safety: AI vision allows robots to detect humans or obstacles and prevent accidents.

- Fast ROI: Smart vision systems often pay for themselves within 1–2 years due to increased productivity and reduced errors.

Critical Note: Implementation costs can be high initially, and AI models require proper training and calibration to achieve peak performance. Some systems may underperform if not integrated carefully into production processes.

Precision Engineering Meets Robotics FAQ

Read more about Robotics & Intelligent Automation in Industry

- Robotics & Intelligent Automation in Industry

- Collaborative Robots (Cobots)

- AI & Machine Vision: How Smart Robots See, Think, and Adapt

- Precision Engineering Meets Robotics

- The Economics of Robotics: Cost, ROI, and When to Automate

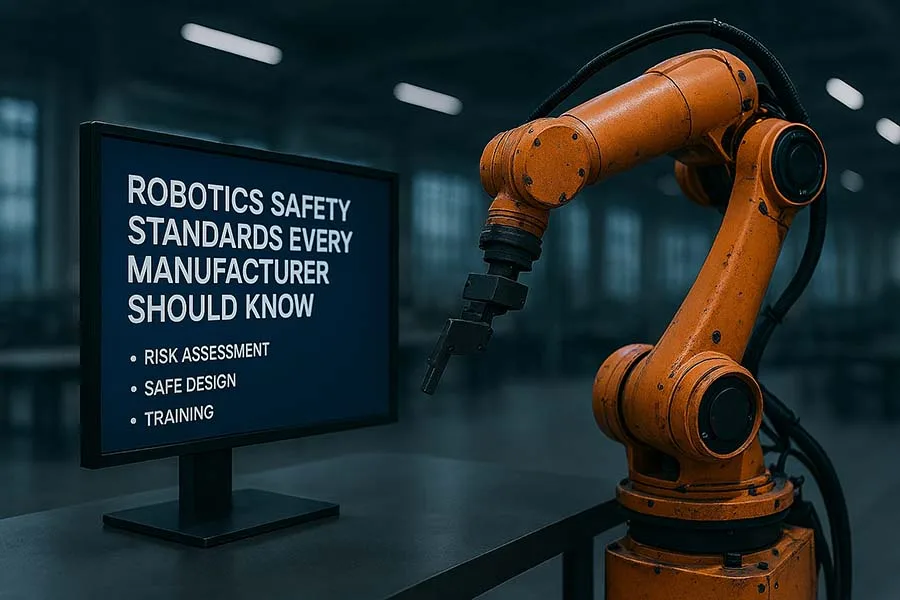

- Robotics Safety Standards Every Manufacturer Should Know

- Humans and Robots: The Reality of Shop Floor Collaboration

- Mobile Robotics and AGVs: The Silent Workforce of Logistics

- Robotics in Small and Medium Manufacturing

- The Future of Industrial Tools in a Robotic World

- Disruptive Trends: AI, 5G, and Digital Twins in Robotics

Conclusion

AI-powered machine vision is revolutionizing the way smart robots interact with the world. By enabling robots to see, think, and adapt, manufacturers can achieve higher efficiency, better quality, and safer workplaces. While initial costs and integration challenges exist, the long-term benefits make AI vision a crucial investment for modern industry.

As AI and machine vision continue to evolve, smart robots will increasingly support human workers, creating a harmonious and highly productive future in manufacturing.

If you find our content helpful, please consider leaving us a quick Trustpilot review — it means a lot! Leave a Review

We’d love to hear your experiences with AI and machine vision in the workplace. Share your thoughts in the comments below and don’t forget to share this article on social media!