Introduction: Why Robotics Matters Today

Manufacturing is changing faster than ever. What was once a labor-intensive, manual process has transformed into a world of robotic arms, automated guided vehicles, and artificial intelligence. Yet the story is not just about speed or cost reduction—it’s about precision, safety, flexibility, and competitiveness in a global marketplace.

This guide serves as your central hub for robotics and automation in manufacturing. We’ll explore every major aspect—from collaborative robots to digital twins—and provide links to in-depth articles that break down each topic further.

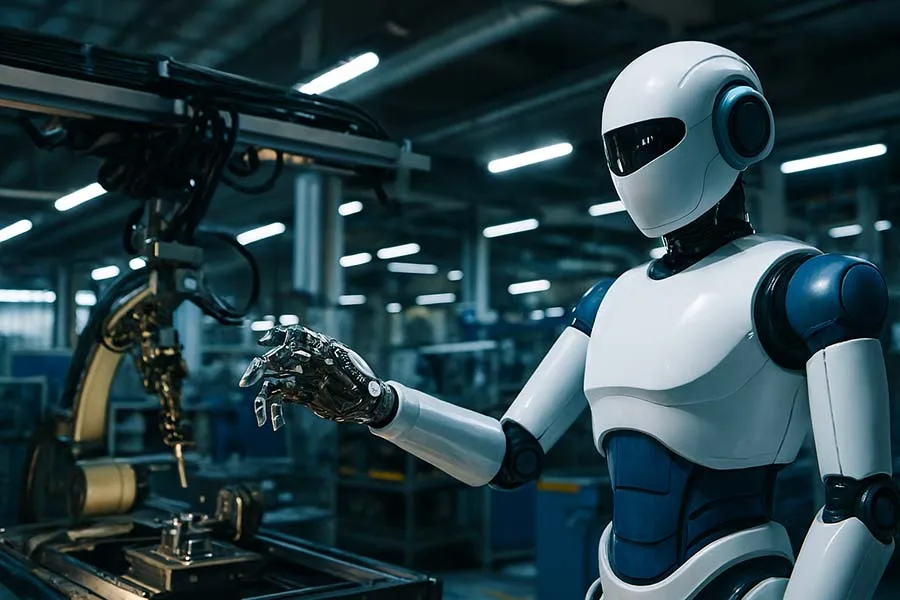

1. Collaborative Robots: The Human-Robot Team

Collaborative robots, or cobots, are no longer a futuristic concept. They work side-by-side with humans, assisting with repetitive or hazardous tasks while improving workplace safety. Unlike traditional robots locked behind cages, cobots are designed to sense, adapt, and stop when necessary.

👉 Read more in our dedicated article:

Collaborative Robots: Cobots Revolutionizing the Factory Floor

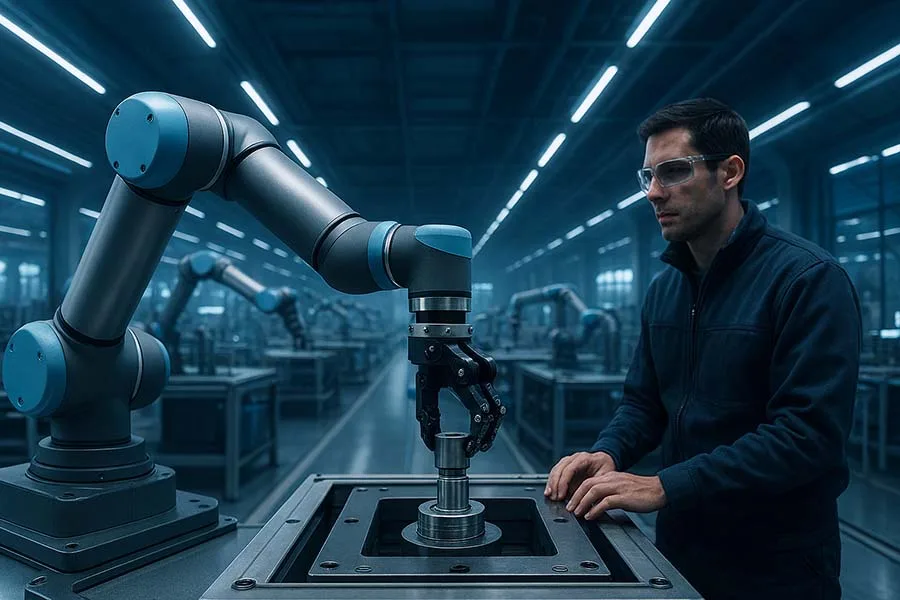

2. Machine Vision and AI: How Robots See and Think

Robots today don’t just move; they see, think, and adapt thanks to AI and machine vision. From identifying defects in real time to guiding robotic arms with micron-level accuracy, vision systems are the eyes of modern automation.

👉 Dive deeper here:

AI + Machine Vision: How Smart Robots See, Think, and Adapt

3. Precision Engineering Meets Robotics

Robotics has become synonymous with extreme accuracy. In industries like aerospace and medical device manufacturing, robots are expected to achieve micron-level tolerances. This blend of robotics and precision engineering is pushing the boundaries of what’s possible.

👉 Explore more:

Precision Engineering Meets Robotics: The Quest for Micron Accuracy

4. The Economics of Robotics: ROI, Cost, and Value

Investing in robotics is a strategic decision. While upfront costs can be high, the long-term ROI in terms of efficiency, quality, and safety often outweighs the expense. Small and large manufacturers alike must weigh productivity gains against initial investment.

👉 Full breakdown here:

The Economics of Robotics: Cost, ROI, and When to Automate

5. Safety Standards Every Manufacturer Should Know

With robots working alongside humans, safety is paramount. International standards like ISO 10218 and ISO/TS 15066 ensure that robotic systems are designed to protect workers. From speed limits to force thresholds, these standards keep factories safe.

👉 Learn the details:

Robotics Safety Standards Every Manufacturer Should Know

6. Human + Robot Collaboration: Beyond the Hype

Forget the fear of “robots taking jobs.” In reality, robots often handle the repetitive, dangerous, or physically exhausting tasks—freeing humans for higher-value work. Successful factories treat robots as colleagues, not competitors.

👉 Real shop-floor insights:

Humans and Robots: The Reality of Shop Floor Collaboration

7. Mobile Robotics and AGVs: The Silent Workforce

Logistics inside factories has quietly been transformed by autonomous guided vehicles (AGVs) and mobile robots. They deliver parts, transport materials, and keep production flowing without human intervention.

👉 Learn how they work:

Mobile Robotics and AGVs: The Silent Workforce of Logistics

8. Robotics in SMEs: Breaking the Myths

One of the biggest misconceptions is that robotics is only for large corporations. In truth, small and medium enterprises (SMEs) are increasingly adopting scalable, affordable robotics solutions to stay competitive.

👉 Fact vs. fiction:

Robotics in Small and Medium Manufacturing: Breaking the Myths

9. The Future of Industrial Tools in a Robotic World

As robotics evolves, so do the tools that support it. From adaptive grippers to torque-controlled fasteners, industrial tools are getting smarter and more integrated with robotic systems.

👉 Read the full vision:

The Future of Industrial Tools in a Robotic World

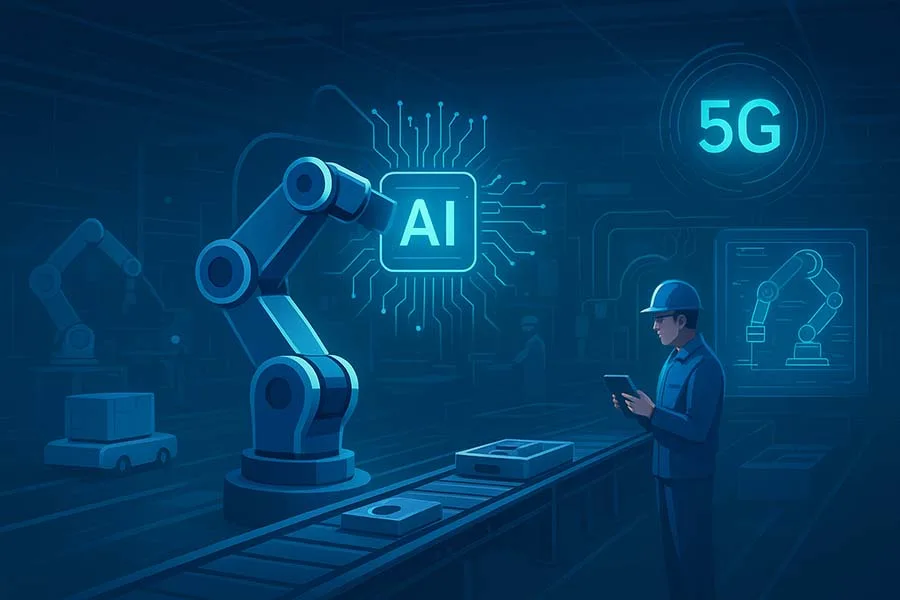

10. Disruptive Trends: AI, 5G, and Digital Twins

The next wave of robotics is powered by AI, ultra-fast 5G connectivity, and digital twin technology. These disruptive trends are making factories smarter, more connected, and capable of predictive decision-making like never before.

👉 Explore the future:

Disruptive Trends: AI, 5G, and Digital Twins in Robotics

Conclusion: The Robotics Revolution Is Already Here

Robotics and automation are no longer optional—they’re the backbone of modern, competitive manufacturing. From cobots to digital twins, the industry is moving toward an era where machines don’t just follow instructions—they learn, adapt, and collaborate.

For manufacturers, the question is no longer if robotics should be adopted, but how quickly. Those who embrace automation today are shaping the future of industry tomorrow.