Introduction

As robotics becomes increasingly integrated into modern manufacturing, safety is paramount. The combination of heavy machinery, high-speed movements, and human interaction creates potential hazards that manufacturers cannot ignore. Following robotics safety standards is essential not only to protect workers but also to ensure regulatory compliance and maintain operational efficiency.

Why Robotics Safety Standards Matter

Robots, whether industrial arms or collaborative cobots, pose unique risks:

- Mechanical Hazards: Crushing, pinching, or collision injuries.

- Electrical Hazards: Shock or fire from faulty wiring or damaged components.

- Operational Hazards: Programming errors or unexpected movements causing accidents.

Interesting Fact: Implementing proper safety standards can reduce workplace accidents by over 50% in automated environments.

By adhering to recognized safety standards, manufacturers mitigate risk, avoid legal issues, and foster a culture of safety.

Key Robotics Safety Standards

1. ISO 10218 – Industrial Robots Safety

- Covers design, installation, and operation of industrial robots.

- Focuses on risk assessment, safe programming, and emergency stop mechanisms.

- Widely recognized internationally as the foundational industrial robotics safety standard.

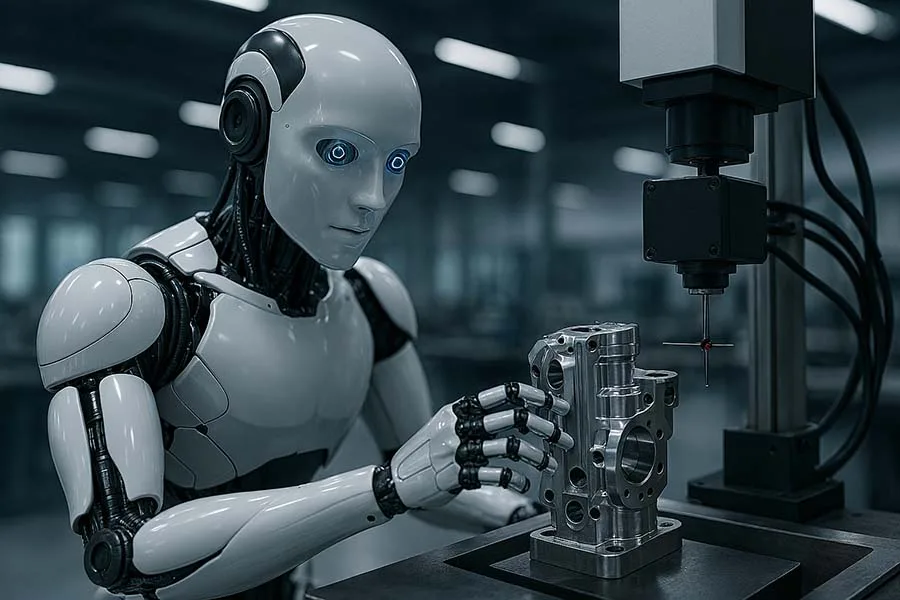

2. ISO/TS 15066 – Collaborative Robots (Cobots)

- Specific to human-robot collaboration.

- Defines maximum allowable forces and pressures during human contact.

- Emphasizes safe workspace design and operator training.

3. ANSI/RIA R15.06 – Robot Safety in the US

- Aligns with ISO standards but tailored for North American regulations.

- Provides guidelines on risk assessment, safeguarding, and emergency systems.

4. IEC 61508 – Functional Safety of Electrical/Electronic Systems

- Applies to robotic control systems, ensuring safe operation under failure conditions.

- Essential for robots with AI or automated decision-making capabilities.

5. OSHA Guidelines – Occupational Safety

- Regulatory guidance for safe integration of robotics into workplaces in the US.

- Covers general safety, training requirements, and emergency response procedures.

Lesser-Known Fact: Many manufacturers overlook ISO/TS 15066 when adopting cobots, potentially underestimating human-robot interaction risks.

Best Practices for Compliance

- Risk Assessment: Conduct detailed risk analysis before deploying any robotic system.

- Operator Training: Ensure all personnel are trained in robot operation, emergency procedures, and safety protocols.

- Emergency Stops & Safety Zones: Install accessible emergency stop buttons and physical or virtual safety zones.

- Regular Maintenance: Schedule routine inspections and software updates to prevent malfunctions.

- Documentation: Keep detailed records of safety checks, training, and incident reports.

Interesting Fact: Some factories use digital twins to simulate human-robot interactions and validate safety before physical deployment.

Robotics Safety Standards Every Manufacturer Should Know FAQ

Read more about Robotics & Intelligent Automation in Industry

- Robotics & Intelligent Automation in Industry

- Collaborative Robots (Cobots)

- AI & Machine Vision: How Smart Robots See, Think, and Adapt

- Precision Engineering Meets Robotics

- The Economics of Robotics: Cost, ROI, and When to Automate

- Robotics Safety Standards Every Manufacturer Should Know

- Humans and Robots: The Reality of Shop Floor Collaboration

- Mobile Robotics and AGVs: The Silent Workforce of Logistics

- Robotics in Small and Medium Manufacturing

- The Future of Industrial Tools in a Robotic World

- Disruptive Trends: AI, 5G, and Digital Twins in Robotics

Conclusion

Robotics safety standards are non-negotiable in modern manufacturing. Compliance protects employees, ensures smooth operations, and safeguards businesses against legal and financial risks. By understanding key standards such as ISO 10218, ISO/TS 15066, ANSI/RIA R15.06, and OSHA guidelines, manufacturers can confidently integrate robots while maintaining the highest level of safety.

Adopting best practices, operator training, and regular audits will not only prevent accidents but also enhance productivity and workplace morale. Safety and automation are not mutually exclusive—they are complementary pillars of modern manufacturing.

If you find our content helpful, please consider leaving us a quick Trustpilot review — it means a lot! Leave a Review

We’d love to hear how your factory or workshop manages robotics safety. Share your experiences in the comments below, and don’t forget to share this article on social media!