Introduction

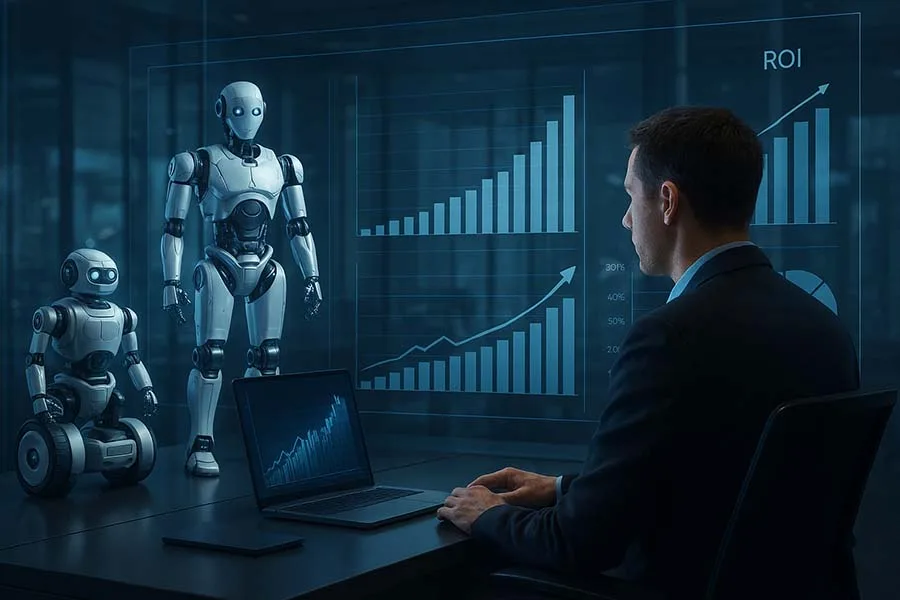

Robotics has moved from the factory floor of large automotive plants to small and medium-sized enterprises worldwide. However, while the technology promises efficiency, safety, and productivity, the decision to automate is ultimately an economic one. Understanding the costs, potential returns, and strategic timing for automation is crucial for businesses aiming to maximize ROI and avoid unnecessary expenses.

Understanding the Costs of Robotics

The costs of implementing robotics are multifaceted and include:

- Initial Investment: Hardware, installation, and integration costs can range from a few thousand to hundreds of thousands of dollars depending on complexity.

- Software & Programming: Robots require specialized programming, AI integration, or vision systems for more advanced tasks.

- Maintenance & Support: Regular maintenance, spare parts, and software updates ensure long-term reliability.

- Training: Employees must learn how to operate, program, and maintain robotic systems safely.

Interesting Fact: Advanced collaborative robots can cost 50–70% less than traditional industrial robots while still offering high performance and flexibility.

Calculating ROI: What to Consider

Return on Investment (ROI) is the cornerstone of any automation decision. Factors influencing ROI include:

- Labor Savings: Reducing repetitive or hazardous tasks decreases human labor costs.

- Productivity Gains: Robots operate 24/7, improving throughput without fatigue.

- Waste Reduction: High-precision automation minimizes errors and defective products.

- Flexibility & Scalability: Cobots and modern robots can adapt to changing production needs, reducing long-term costs.

Critical Note: ROI is not immediate in every case. Some projects may require 1–3 years to recoup the initial investment, especially for complex installations or highly customized robotic systems.

When Should You Automate?

Automation is most economically viable under these circumstances:

- High Labor Costs: When wages are significant, automation reduces operational expenses.

- Repetitive or Hazardous Tasks: Robots excel in roles that are physically demanding, dangerous, or monotonous.

- High-Precision Requirements: Tasks requiring extreme accuracy or consistency are prime candidates for robotics.

- Growth or Scalability Needs: When production volume increases or fluctuates, robots help maintain efficiency.

Lesser-Known Fact: Some manufacturers delay automation until labor shortages hit a tipping point; strategic planning can actually maximize ROI.

Hidden Costs and Pitfalls

While robotics offers significant benefits, there are economic pitfalls to watch out for:

- Underutilization: Robots sitting idle due to poor planning or lack of integration reduce ROI.

- Integration Complexity: Retrofitting older production lines can increase costs significantly.

- Maintenance Surprises: Unexpected breakdowns or software issues can create downtime and additional expense.

- Over-Automation: Automating low-value tasks or rarely performed operations may never pay back the investment.

Interesting Fact: Companies that carefully analyze task value and production bottlenecks before automation achieve higher ROI and faster payback periods.

Economic Models: Leasing vs. Buying

- Buying: Higher upfront cost, long-term ownership, and full control over the system.

- Leasing or Robotics-as-a-Service (RaaS): Lower initial cost, flexible scaling, and easier upgrades, though long-term expenses may be higher.

Selecting the right model depends on your capital availability, production requirements, and strategic flexibility.

The Economics of Robotics FAQ

Read more about Robotics & Intelligent Automation in Industry

- Robotics & Intelligent Automation in Industry

- Collaborative Robots (Cobots)

- AI & Machine Vision: How Smart Robots See, Think, and Adapt

- Precision Engineering Meets Robotics

- The Economics of Robotics: Cost, ROI, and When to Automate

- Robotics Safety Standards Every Manufacturer Should Know

- Humans and Robots: The Reality of Shop Floor Collaboration

- Mobile Robotics and AGVs: The Silent Workforce of Logistics

- Robotics in Small and Medium Manufacturing

- The Future of Industrial Tools in a Robotic World

- Disruptive Trends: AI, 5G, and Digital Twins in Robotics

Conclusion

The economics of robotics hinges on strategic investment, careful planning, and task selection. By analyzing costs, potential ROI, and optimal timing for automation, manufacturers can maximize efficiency, reduce errors, and future-proof operations.

While challenges exist—such as integration complexity, maintenance, and upfront investment—smart deployment ensures long-term benefits that far outweigh initial expenses. In today’s competitive market, understanding the financial impact of robotics is as crucial as the technology itself.

If you find our content helpful, please consider leaving us a quick Trustpilot review — it means a lot! Leave a Review

We’d love to hear your experiences with robotics investments and automation strategy. Share your thoughts in the comments below and don’t forget to share this article on social media!