Introduction: Tools Meet Robots

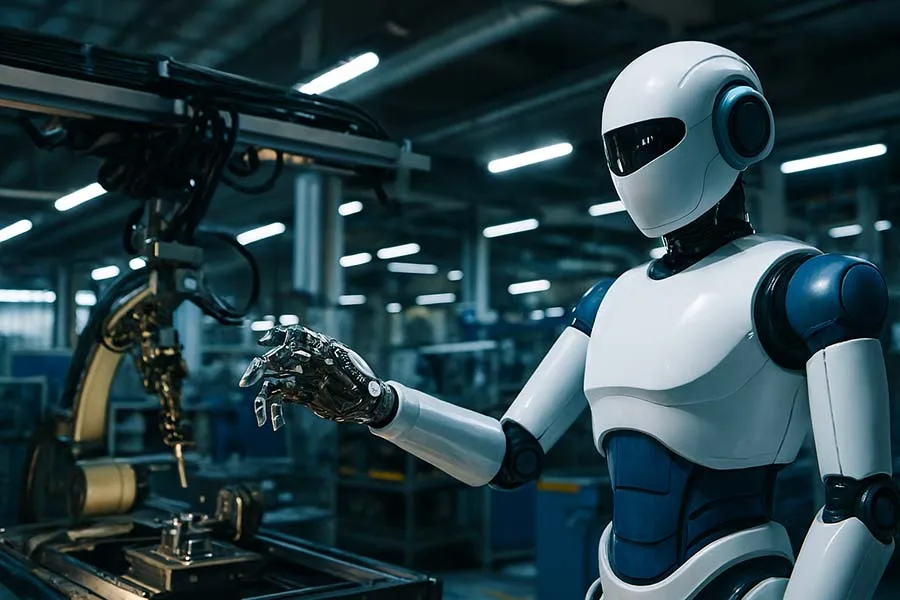

For centuries, tools have defined human progress—from the first stone hammer to the modern CNC spindle. But today, industrial tools are no longer just passive instruments waiting for human hands. In a robotic world, tools are becoming smarter, adaptive, and interconnected.

Think of torque wrenches that talk to robots, drills that self-correct based on sensor feedback, or inspection tools guided by AI vision. The future of industrial tools isn’t about replacement—it’s about integration.

The Convergence: Tools and Robotics as One

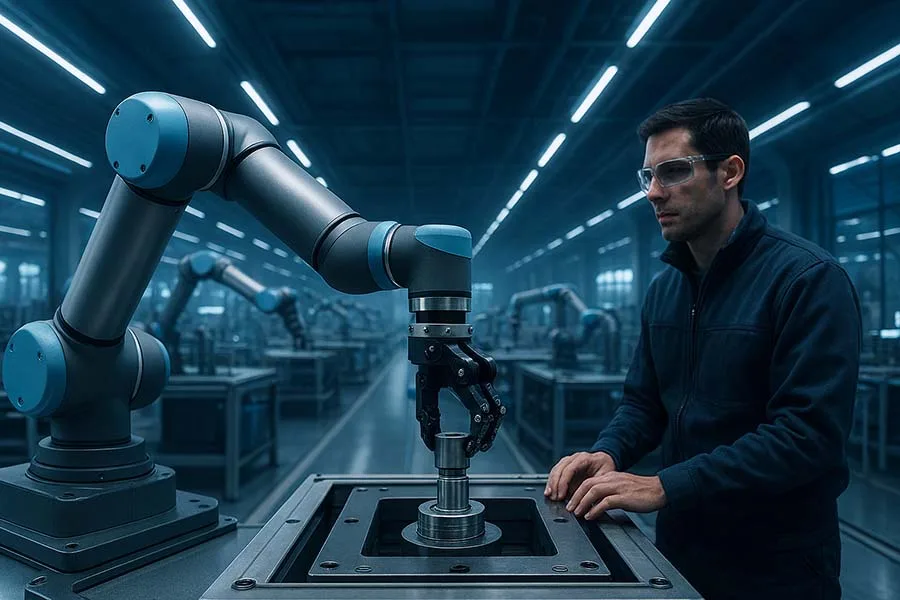

Traditionally, tools were designed for humans, and machines were designed for production. But now, the boundary is blurring:

- Smart Tools: Equipped with IoT sensors, they track performance and detect wear.

- Adaptive Interfaces: Robots can swap end-effectors like wrenches, grippers, and cutters within seconds.

- Collaborative Precision: Tools are designed not just for strength but for data capture—feeding robots with real-time feedback.

This convergence creates a new manufacturing ecosystem where tools aren’t just used—they communicate, optimize, and evolve.

Key Trends in Robotic Tooling

| Trend | Description | Real-World Example |

|---|---|---|

| IoT-enabled tools | Tools with built-in sensors for data tracking and predictive maintenance | Smart torque wrenches logging every bolt tightening |

| AI-driven inspection | Cameras and scanners that integrate with robots for automatic quality control | Vision-guided robotic arms in automotive lines |

| Modular tooling systems | Quick-change systems allow robots to adapt multiple tasks | Cobots swapping between screwdrivers and polishers |

| Digital twins | Virtual replicas simulate tool performance before production | Aerospace industry tool path optimization |

| Wearable robotics | Tools enhanced with exoskeletons for human workers | Exosuits assisting heavy tool handling |

Funny Fact

In one German factory, a cobot equipped with a screwdriver was nicknamed “Bob the Builder” by workers—because it tirelessly tightened screws with perfect torque, while employees joked that Bob “never asked for a coffee break.”

Lesser-Known Fact

Some cutting-edge robotic welding torches now include built-in AI that analyzes the arc in real-time, adjusting speed and angle to maintain weld quality—something even the most skilled human welder can’t consistently achieve.

Challenges on the Horizon

Even with innovation, hurdles remain:

- Cost barriers for smaller manufacturers adopting smart robotic tools.

- Compatibility issues between legacy machines and new robotic tooling systems.

- Skill gaps—operators must learn how to manage software-driven tools.

Yet, history shows us that tools always evolve. The plow gave way to tractors. The wrench is giving way to smart torque systems. And tomorrow, perhaps, robots will not just use tools—they’ll design them.

The Future of Industrial Tools in a Robotic World FAQ

Read more about Robotics & Intelligent Automation in Industry

- Robotics & Intelligent Automation in Industry

- Collaborative Robots (Cobots)

- AI & Machine Vision: How Smart Robots See, Think, and Adapt

- Precision Engineering Meets Robotics

- The Economics of Robotics: Cost, ROI, and When to Automate

- Robotics Safety Standards Every Manufacturer Should Know

- Humans and Robots: The Reality of Shop Floor Collaboration

- Mobile Robotics and AGVs: The Silent Workforce of Logistics

- Robotics in Small and Medium Manufacturing

- The Future of Industrial Tools in a Robotic World

- Disruptive Trends: AI, 5G, and Digital Twins in Robotics

- Best Smart Tightening Tools for Industrial Assembly (2025 Guide)

Conclusion: Tools That Think, Robots That Build

The future of industrial tools isn’t about losing the human touch—it’s about amplifying it. As robotics and AI evolve, tools will no longer be simple extensions of human hands, but partners in precision manufacturing.

In a robotic world, tools don’t just work.

They think.

They adapt.

And together with robots, they build the future of industry.