Introduction

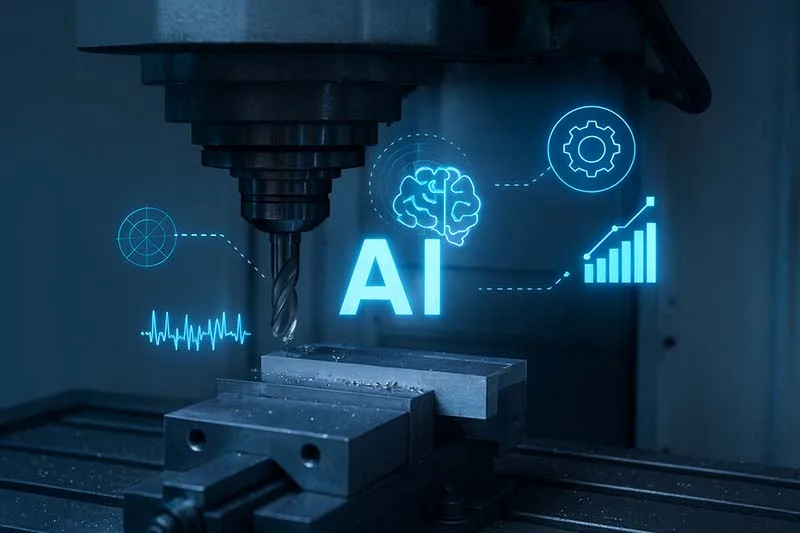

The CNC industry isn’t just about precision cutting and tooling anymore—it’s about intelligence. With AI (Artificial Intelligence) and machine learning now entering the shop floor, CNC machines are becoming smarter, faster, and more autonomous than ever before.

In this article, we’ll explore how AI and machine learning are changing the face of CNC machining, the benefits they bring, and what it means for the future of manufacturing.

What Is AI in CNC?

AI in CNC refers to integrating algorithms and learning models into machining processes. Instead of simply following pre-programmed instructions, the CNC system can:

- Learn from data

- Predict problems before they occur

- Adapt machining strategies in real time

This shift is what transforms a CNC machine from being just “computer-controlled” to becoming intelligent and adaptive.

Key Applications of AI and Machine Learning in CNC

1. Predictive Maintenance

AI can monitor sensors inside the machine to detect early signs of wear, vibration, or overheating. Instead of shutting down for scheduled maintenance, the system tells operators exactly when intervention is needed, saving both downtime and money.

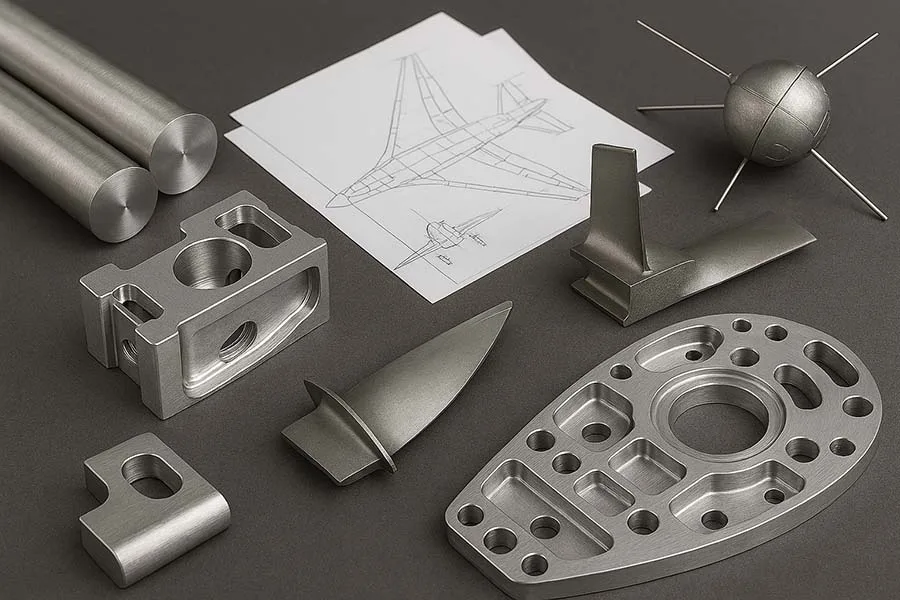

2. Adaptive Machining

Traditional CNCs follow fixed tool paths. AI-driven systems analyze cutting forces, tool wear, and material inconsistencies, then adjust in real time for maximum precision.

3. Quality Control with Computer Vision

Machine learning models paired with cameras can automatically inspect parts for defects, catching errors before they reach customers.

4. Energy Efficiency

Smart algorithms reduce unnecessary tool movement and optimize spindle speed, making machining more sustainable and cost-effective.

5. Autonomous Decision-Making

Some advanced CNC setups can now self-correct mid-operation, reducing human intervention and boosting reliability.

Advantages of AI in CNC

- Reduced downtime through predictive maintenance

- Increased efficiency and speed

- Improved product quality with fewer defects

- Lower energy costs

- Scalability for Industry 4.0

Challenges and Limitations

While the benefits are huge, AI integration isn’t without hurdles:

- High upfront cost for AI-enabled systems

- Need for skilled operators trained in both CNC and data science

- Data quality issues, since bad data can lead to poor predictions

- Cybersecurity risks in connected smart factories

The Future of AI in CNC Machining

Expect to see CNC machines become fully connected, self-learning systems. As machine learning models evolve, they’ll handle more complex parts, faster setups, and even automated problem-solving—bringing us closer to lights-out manufacturing (factories that run 24/7 without human supervision).

Funny Fact

Some engineers joke that future CNC machines will be so smart, they’ll ask for a “coffee break” after finishing a high-volume run. Luckily, AI hasn’t developed caffeine cravings—yet.

Lesser-Known Fact

AI-driven CNC systems are already being tested for multi-sensor fusion—where vibration, sound, and even tool temperature data are combined for ultra-accurate machine learning predictions.

Want To Read More?

- CNC Machining Processes & Technologies

- CNC Workflow: From CAD to Finished Part

- Tooling and Fixtures in CNC

- Multi-Axis Machining: 3-Axis vs 5-Axis

- AI and Machine Learning in CNC: The Future of Smart Manufacturing

- Predictive Maintenance and IoT in CNC

- Digital Twins in CNC Systems

Conclusion

AI and machine learning are more than just buzzwords—they are becoming the new backbone of CNC machining. From predictive maintenance to adaptive cutting, these technologies are reshaping how factories operate.

Manufacturers that embrace AI today will gain a strong competitive edge tomorrow.

👉 What do you think—will AI replace machinists, or simply make their work more powerful? Share your thoughts in the comments below!