Introduction

Industrial automation is no longer a futuristic concept—it’s here, running factories, optimizing warehouses, and keeping production lines humming around the clock. At the heart of this transformation are automation machines, purpose-built systems that perform tasks faster, safer, and more accurately than humans ever could. But what exactly qualifies as an automation machine, and why are they so vital in modern industry? Let’s break it down.

What Are Automation Machines in Industry?

Automation machines are mechanical or digital systems designed to perform repetitive, complex, or dangerous tasks with minimal human intervention. They combine hardware, sensors, controllers, and software to deliver consistent performance.

Think of them as the backbone of Industry 4.0—machines that don’t just follow instructions but increasingly make real-time decisions using AI and data analytics.

Types of Automation Machines for Industry

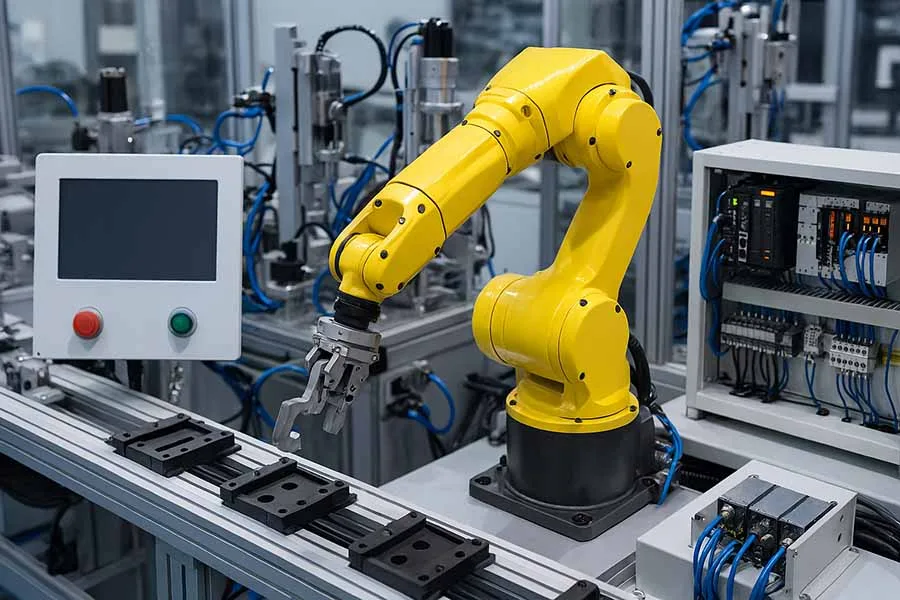

1. Robotic Arms

- Used in: automotive assembly, electronics, packaging

- Capabilities: welding, painting, material handling, pick-and-place tasks

2. CNC Machines (Computer Numerical Control)

- Used in: precision machining, aerospace, metalworking

- Capabilities: milling, turning, drilling with micron-level accuracy

3. Automated Guided Vehicles (AGVs)

- Used in: warehouses, logistics centers, automotive plants

- Capabilities: material transport, just-in-time delivery, integration with WMS/ERP

4. Packaging and Palletizing Systems

- Used in: food & beverage, pharmaceuticals, e-commerce

- Capabilities: high-speed packing, labeling, shrink-wrapping, robotic palletizing

5. Automated Inspection and Quality Control Systems

- Used in: electronics, automotive, medical devices

- Capabilities: vision systems, defect detection, non-contact measurements

6. 3D Printing and Additive Manufacturing Machines

- Used in: prototyping, aerospace, healthcare

- Capabilities: rapid production, design flexibility, waste reduction

Key Benefits of Automation Machines

- Productivity boost: operate 24/7 without breaks

- Consistency and accuracy: eliminate human error in repetitive tasks

- Safety improvements: reduce workplace accidents in hazardous environments

- Cost savings: lower labor costs and minimize waste

- Scalability: adapt production lines quickly to changing demands

Challenges and Considerations

While automation machines bring undeniable advantages, industries must navigate:

- High upfront investment costs

- Training requirements for workforce adaptation

- Integration with existing legacy systems

- Cybersecurity risks in connected environments

Future Trends in Automation Machines

- AI-powered robotics: machines that self-learn and adapt

- Collaborative robots (cobots): working side by side with humans

- Predictive maintenance: AI detecting failures before they happen

- Sustainable automation: energy-efficient machines with circular economy design

- Hyper-automation: integration of multiple automation technologies into a seamless ecosystem

Funny Fact

In one famous experiment, engineers programmed a robotic arm to make pancakes. The result? Perfect circles every time—except when the AI decided the pan was optional and flipped them straight onto the floor. Proof that even robots need cooking classes.

Lesser-Known Fact

The first automated machine tool dates back to 1801, when French inventor Joseph Marie Jacquard created the Jacquard loom. It used punch cards to automate weaving patterns—an early ancestor of today’s CNC and even computer programming.

Further Read

- Industrial Automation Solutions

- Industrial Automation Systems: The Backbone of Modern Industry

- Process Automation in Manufacturing: The Key to Smarter Production

- Automation Companies to Watch in 2025 and Beyond

- Automation Machines for Industry: Types, Benefits, and Future Trends

- Automated Material Handling Solutions: Benefits, Types & Future Trends

- Automated Control Systems

- Industrial Automation Solutions: Transforming Modern Manufacturing

- Warehouse Automation Tools: Boosting Efficiency in Modern Warehouses

- Intelligent Automation Technologies: The Future of Industry

- Automated Packaging Systems

- Automation Case Studies

- Automation Trends 2025: What’s Next for Industrial Innovation

Conclusion

Automation machines are more than just tools; they are reshaping the future of industry. From robotic arms to AI-driven quality control systems, they enable safer, faster, and more efficient production across virtually every sector.

Industries that adopt these machines aren’t just keeping up with technology—they’re future-proofing their operations.

👉 What automation machine fascinates you the most—robots, CNCs, or futuristic cobots? Share your thoughts in the comments below and let’s spark a discussion!