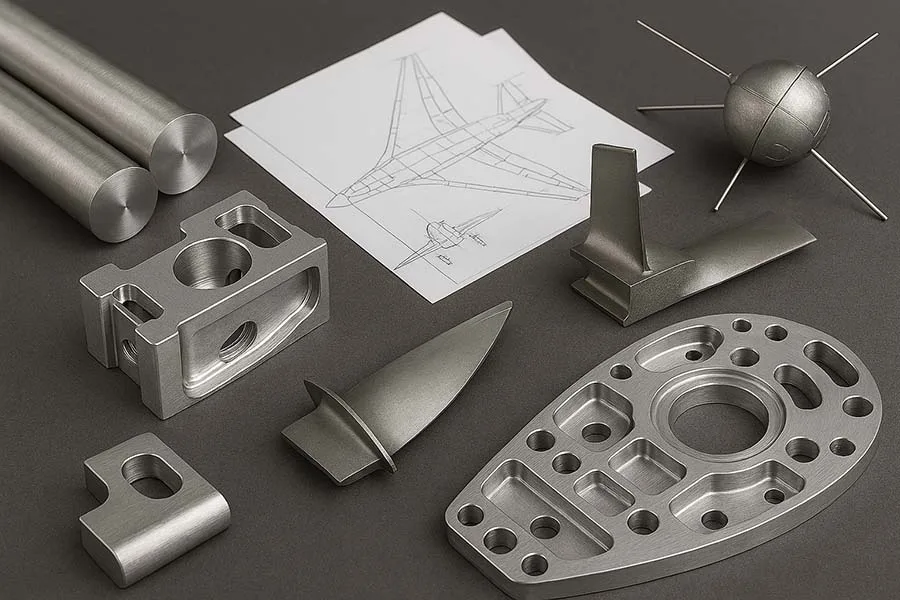

CNC machining is the backbone of modern aerospace manufacturing, allowing engineers to produce high-precision, reliable components for aircraft, spacecraft, and satellites. With tolerances often under 0.01 mm and complex geometries that traditional methods cannot achieve, CNC technology ensures that safety, performance, and efficiency standards are met.

In this guide, we’ll explore how CNC is applied in aerospace, the materials involved, key machining processes, quality standards, emerging trends, and practical considerations for manufacturers.

Why CNC is Critical in Aerospace

CNC machining is essential for aerospace due to the high stakes of precision, repeatability, and safety. Key reasons include:

- High Precision: Critical components like turbine blades, landing gear, and engine parts require extreme accuracy.

- Repeatability: Every component must meet exact specifications to ensure safety and performance.

- Complex Geometries: Aircraft and spacecraft parts often have intricate shapes impossible with conventional machining.

- Efficiency: CNC reduces production time and ensures uniformity in both prototyping and final production.

Fun Fact: Some aerospace CNC machines operate 24/7, producing parts for hundreds of airplanes each year.

Materials Used in Aerospace CNC Machining

Material selection is crucial in aerospace because every gram counts and parts must withstand extreme conditions. The most common materials include metals, superalloys, and composites.

1. Metals

| Metal | Properties | Machinability | Typical Aerospace Use |

|---|---|---|---|

| Aluminum | Lightweight, corrosion-resistant, excellent thermal conductivity | Excellent | Fuselage panels, structural components |

| Titanium | Extremely strong, lightweight, corrosion-resistant | Challenging | Engine parts, landing gear, airframes |

| Stainless Steel | High strength, durable, corrosion-resistant | Moderate | Structural supports, fasteners, mechanical assemblies |

| Nickel-based Superalloys | Heat-resistant, extremely strong | Difficult | Jet engine turbine blades, high-temperature components |

Tip: Aluminum is often used for fuselage and wing panels due to its lightweight nature, while titanium is reserved for critical structural components that require both strength and corrosion resistance.

2. Composites

| Composite | Properties | Machinability | Typical Use |

|---|---|---|---|

| Carbon Fiber | High strength-to-weight, rigid | Requires specialized tooling | Fuselage, wing components, satellite panels |

| Fiberglass | Durable, corrosion-resistant | Easier than carbon fiber | Interior panels, secondary structures |

| Reinforced Plastics | Lightweight, tough | Moderate | Instrument housings, interior components |

Lesser-Known Fact: Some modern aerospace parts use hybrid composite-metal structures, combining carbon fiber layers with aluminum or titanium for optimized performance.

CNC Machining Processes in Aerospace

Aerospace parts often require multiple machining processes. CNC allows multi-axis, high-precision operations that traditional methods cannot achieve.

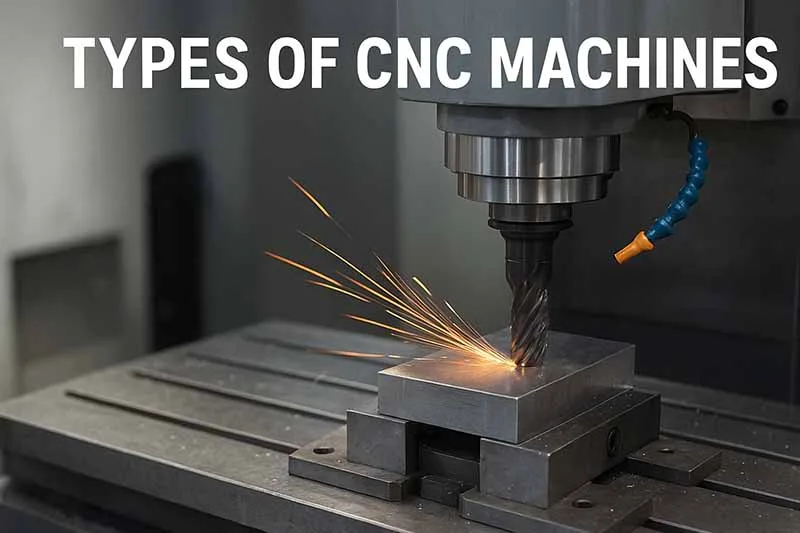

1. Milling

- Produces 3D shapes for structural components and engine parts.

- Can be done on 3, 4, or 5-axis machines depending on complexity.

2. Turning

- Used for cylindrical components like shafts, landing gear rods, and engine spindles.

- High-precision turning ensures dimensional accuracy.

3. Drilling & Boring

- Creates holes for fasteners, fuel lines, or assemblies.

- CNC ensures perfect alignment and depth across multiple parts.

4. Multi-Axis Machining

- 5-axis CNC machines allow simultaneous machining from multiple angles, critical for complex aerospace parts like turbine blades.

Tip: Multi-axis machines reduce setup times and allow more intricate parts without sacrificing precision.

Quality and Safety Standards

Aerospace components must comply with strict regulations:

- FAA (Federal Aviation Administration) and EASA (European Union Aviation Safety Agency) standards.

- ISO 9001 and AS9100 quality management systems.

- Inspection methods include:

- CMM (Coordinate Measuring Machines) for dimensional accuracy

- Laser scanning for surface verification

- X-ray or CT scans for internal defects

Practical Tip: CNC machining inherently supports traceability and repeatability, which is critical for compliance and auditing in aerospace manufacturing.

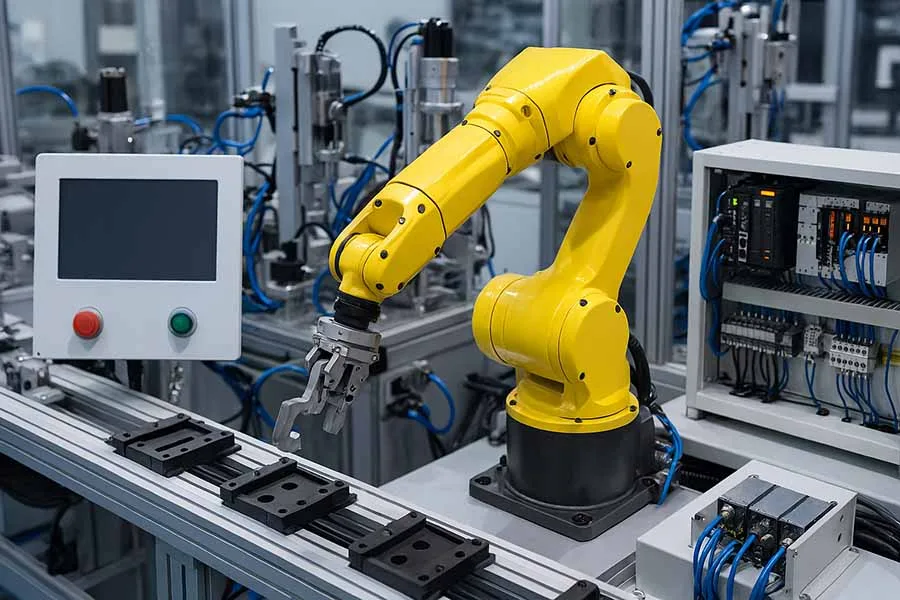

Emerging Trends in Aerospace CNC

- Additive-CNC Hybrid Manufacturing: Combines 3D printing and CNC milling to produce complex, lightweight components.

- Automation & AI Integration: Real-time monitoring detects tool wear, prevents defects, and improves efficiency.

- Sustainable Manufacturing: Optimizing material usage, recycling scrap, and reducing energy consumption.

Fun Fact: Some aerospace manufacturers now integrate AI-driven simulations to predict tool wear before cutting a single part, saving thousands in wasted materials.

Choosing the Right CNC Solution for Aerospace

When selecting a CNC solution for aerospace applications:

- Machine Type: Multi-axis machines (4–5 axes) are preferred for complex geometries.

- Tooling: Must handle hard alloys and composites without excessive wear.

- Material Expertise: Engineers and machinists must understand material-specific cutting parameters.

- Collaboration: Designers, material scientists, and CNC programmers work together to optimize performance.

CNC in Aerospace Manufacturing FAQ

Read more about CNC Materials & Applications

- CNC Materials & Applications

- CNC in Energy & Oil Equipment

- Materials Used in CNC Machining

- CNC in Aerospace Manufacturing: Precision, Materials, and Technology

- CNC in Automotive Production

- CNC in Medical Devices

Conclusion

CNC machining is essential for the aerospace industry, enabling manufacturers to produce complex, high-precision components with unmatched consistency. From lightweight alloys to advanced composites, understanding materials, processes, and emerging trends ensures safer, more efficient, and innovative aerospace designs.

CTA: Explore our Industrial Tools Academy courses to learn more about CNC machining and aerospace applications.