What Is CNC Machining?

CNC machining—short for Computer Numerical Control machining—is a subtractive manufacturing process where computer-guided tools remove material from a solid block (metal, plastic, wood, composites) to create precise, custom-designed parts. The process uses G-code and M-code—programming languages that instruct machines on movement, feed, speed, and tool changes.

In a typical workflow:

- A CAD model is designed.

- CAM software converts it into G-code.

- The machine is prepared (tools, stock material set up).

- The CNC machine executes the code—machine moves along axes, shaping the part.

- Post-processing and inspection follow.

Specialized features like canned cycles automate repetitive tasks (e.g., drilling, threading), enhancing efficiency. Some CNC systems even include automatic tool changers (ATCs), reducing downtime and enabling complex tool sequences.

Advantages – What CNC Machining Excels At

- Exceptionally High Precision & Consistency

Achieves tolerances as tight as 0.001 mm, delivering uniform quality across batches. - Versatile & Complex Geometries

Capable of machining intricate contours in materials from metals to composites. - Efficiency & Repeatability

Once programmed, machines can run with minimal human intervention—ideal for prototyping to medium-volume runs. - Design Retention & Reproducibility

Programs can be saved and reused, ensuring identical output regardless of operator. - Adaptability & Cost Flexibility

CAM software allows quick reprogramming for new parts; smart design choices can reduce costs.

Limitations – What to Watch Out For

- High Initial Cost & Setup Overhead

CNC machines demand significant capital investment, plus time and expertise to program and set up. - Material Waste

Subtractive nature means removed material often becomes scrap—less sustainable than additive methods. - Size & Accessibility Constraints

Machine enclosures limit working volume; hidden or internal features may need multiple setups or 5-axis milling. - Specialized Training Required

Operators need CAD/CAM proficiency and machining know-how. Automation may lead to erosion of manual machining skills. - Operational Costs & Maintenance

Tool wear, calibration, maintenance—plus, program errors can ruin parts—add ongoing costs.

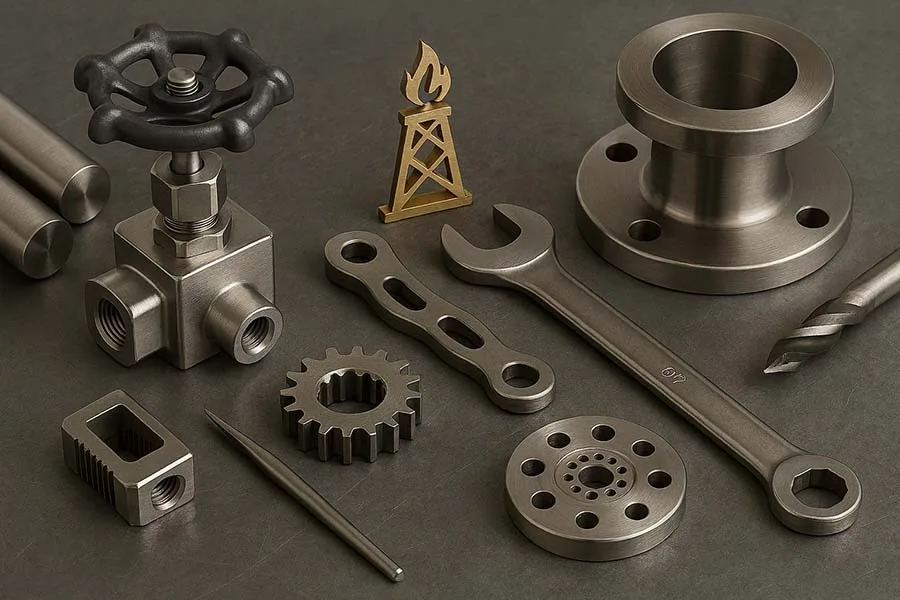

Applications & Industries

- Aerospace & Defense: High-tolerance parts like airfoils, landing gear, titanium components.

- Medical Devices: Implants, surgical instruments with tight specs.

- Rapid Prototyping & Molds: Quick iterations, injection mold tooling.

- General Manufacturing: Automotive, electronics, agriculture, construction, and more.

Interesting Fact

The CNC revolution began in the 1940s with punched-card NC machines; by the 1970s, CNC with computerized controls took over, leading to today’s digital manufacturing era.

Lesser-Known Tip

Some CNC systems support sophisticated Bayesian-optimized operations, balancing feed rate, spindle speed, and depth of cut for both energy efficiency and surface finish—pushing green and precision goals simultaneously.

CNC Machining Explained FAQ

Want To Learn More?

- CNC Machining Fundamentals

- CNC Machining Explained: Precision, Process & Possibilities

- CNC Technology: From Punched Tape to Smart Machining

- Types of CNC Machines (Lathe, Mill, Router, Plasma, etc.)

- CNC Programming Languages (G-code, M-code)

- Most Common CNC Programming Errors

- CNC vs Manual Machining: Differences, Pros & Cons Explained

Wrap-Up

CNC machining is a powerful, precise, and adaptable manufacturing process that has transformed industries. It comes with challenges—costs, waste, training—but those are outweighed by its precision, speed, and scalability. As automation and optimization continue to evolve, CNC remains at the core of modern production.