Introduction: Why CNC Training & Support Matters

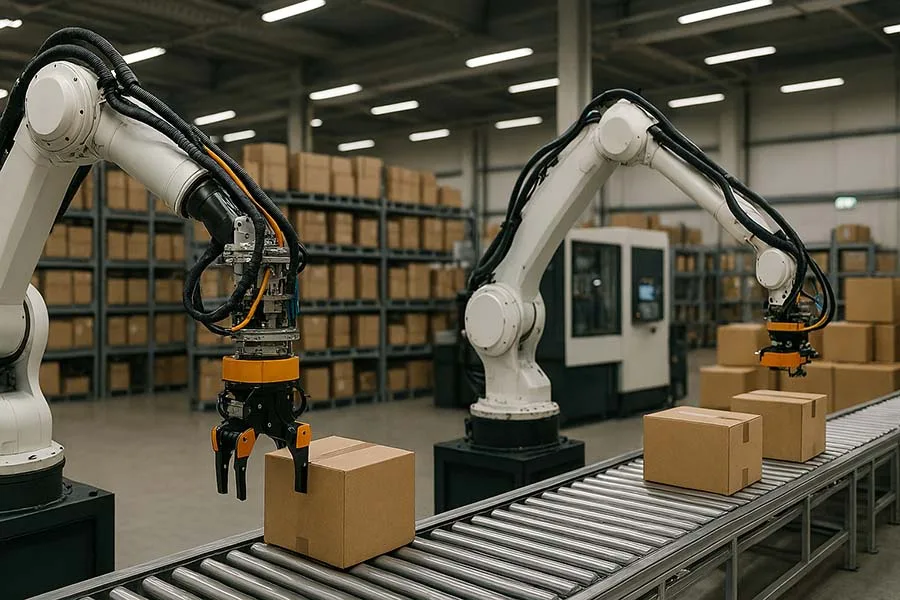

CNC machining is at the heart of modern manufacturing, delivering unmatched precision and productivity. But even the best machines are only as effective as the people operating them. Training and support in CNC machining are crucial for ensuring skilled operators, safe work environments, and efficient production workflows.

This subcluster hub brings together essential guides, from operator certifications and safety practices to FAQs and a comprehensive glossary of CNC terms. Whether you’re a beginner or an experienced professional, this resource ensures you stay confident, knowledgeable, and productive in a CNC shop.

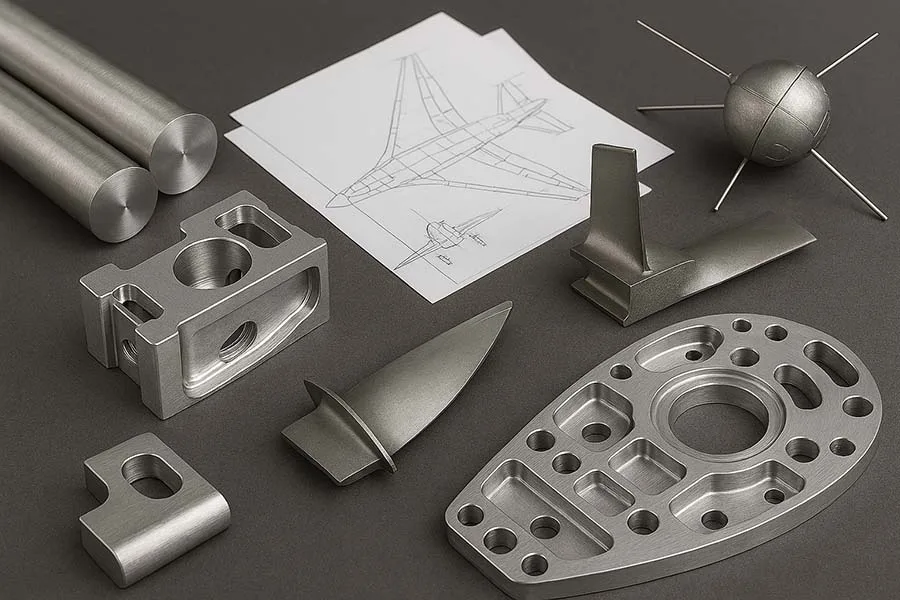

CNC Machining: The Backbone of Modern Manufacturing

Explore the full CNC Machining knowledge hub—where each subcluster dives deep into a specific area of expertise. From buying guides and brand comparisons to training, safety, and troubleshooting, this is your complete resource for mastering CNC. Navigate seamlessly between topics and build your understanding with precision.

1. CNC Operator Certification Paths

Certifications are the gold standard for validating CNC skills. This guide covers the most recognized certification programs, including NIMS, OEM-specific training, and apprenticeship pathways. Certification benefits include higher job security, career advancement, and enhanced technical competence.

2. Best Practices for CNC Safety

Safety is a non-negotiable part of CNC operations. This guide outlines best practices for PPE, machine maintenance, proper setup, and emergency procedures to minimize risks and protect both operators and machines. Following these practices not only prevents accidents but also boosts productivity.

3. FAQs About CNC Machining

Even experienced machinists have questions about accuracy, materials, software, and industry applications. This FAQ guide provides clear answers to the most common CNC-related questions, from costs and tolerances to 3D printing vs. CNC machining, helping operators make informed decisions.

4. Glossary of CNC Terms

The CNC world has its own language — from G-code to multi-axis machining. This glossary defines essential terms and acronyms, ensuring that operators, engineers, and managers can communicate effectively and avoid costly mistakes.

Why CNC Training & Support Is Important

- Improves Operator Efficiency – Skilled operators can run machines faster and more accurately.

- Reduces Downtime and Errors – Proper training prevents crashes, scrap parts, and costly repairs.

- Enhances Workplace Safety – Knowledgeable operators follow safety protocols, protecting themselves and coworkers.

- Supports Career Growth – Certifications and technical knowledge boost employability and salary potential.

- Keeps Your Shop Competitive – Well-trained staff can adapt to new machines, software, and industry trends.

Conclusion

CNC machining is more than machines — it’s people, knowledge, and best practices combined. The CNC Training & Support hub provides everything you need to stay informed, safe, and effective on the shop floor. From certifications to safety, FAQs, and terminology, these resources empower operators and managers to maximize the value of their CNC investments.

Call to Engagement

Which CNC training resource do you rely on most — certifications, safety guides, or reference materials? Share your experiences in the comments and help others level up their CNC skills!