CNC (Computer Numerical Control) machining has revolutionized modern manufacturing across industries. From aerospace and automotive to medical devices and energy equipment, CNC enables high-precision, repeatable, and efficient production.

This guide explores the materials used in CNC machining, how they are applied across industries, key processes, and best practices. It also links to in-depth articles in our CNC cluster for readers who want to dive deeper into each application.

Why CNC Machining Matters Across Industries

CNC machining offers a combination of precision, efficiency, and versatility that is unmatched by traditional methods:

- Extreme Precision: Critical for aerospace turbines, medical implants, and automotive engine components.

- Repeatability: Identical parts can be produced across hundreds or thousands of units.

- Complex Geometries: CNC handles shapes and designs that are impossible to achieve manually.

- Material Versatility: Metals, plastics, and composites can all be machined to tight tolerances.

Fun Fact: CNC machines are used to produce components with tolerances less than 0.01 mm, crucial in industries like aerospace and medical devices.

Materials Used in CNC Machining

Different materials are chosen based on their mechanical properties, weight, cost, and application requirements.

1. Metals

| Metal | Properties | Typical Industries | Common Components |

|---|---|---|---|

| Aluminum | Lightweight, corrosion-resistant | Automotive, Aerospace | Body panels, engine blocks, fuselage panels |

| Steel | High strength, durable | Automotive, Energy | Chassis, valves, pump housings |

| Stainless Steel | Corrosion-resistant, biocompatible | Medical, Energy | Surgical instruments, valves, fasteners |

| Titanium | Lightweight, strong, corrosion-resistant | Aerospace, Medical | Engine parts, implants, landing gear |

| Nickel-based Superalloys | Heat-resistant, wear-resistant | Aerospace, Energy | Turbine blades, high-temperature components |

Tip: Material selection balances weight, strength, machinability, and regulatory requirements.

2. Plastics

| Plastic | Properties | Typical Industries | Common Components |

|---|---|---|---|

| ABS | Lightweight, impact-resistant | Automotive, Medical | Dashboards, housings, instrument panels |

| PEEK | High strength, biocompatible | Medical | Implants, surgical tools |

| Polycarbonate | Transparent, durable | Automotive, Medical | Instrument covers, housings |

| Nylon (PA) | Low friction, wear-resistant | Automotive, Medical | Gears, bushings, connectors |

Lesser-Known Fact: Some automotive and medical devices use reinforced polymers for high performance under load.

3. Composites

| Composite | Properties | Typical Industries | Common Components |

|---|---|---|---|

| Carbon Fiber | Lightweight, strong | Aerospace, Automotive, Medical | Fuselage panels, body panels, prosthetics |

| Fiberglass | Durable, corrosion-resistant | Automotive, Energy | Structural panels, protective covers |

| Reinforced Polymers | Tough, stable | Medical, Automotive | Instrument housings, trims |

CNC Machining: The Backbone of Modern Manufacturing

Explore the full CNC Machining knowledge hub—where each subcluster dives deep into a specific area of expertise. From buying guides and brand comparisons to training, safety, and troubleshooting, this is your complete resource for mastering CNC. Navigate seamlessly between topics and build your understanding with precision.

CNC Applications Across Industries

CNC technology is applied differently depending on industry demands, part geometry, and material.

Aerospace Manufacturing

- Produces turbine blades, engine components, and fuselage panels.

- Requires high precision and multi-axis machining.

Automotive Production

- Engine blocks, transmission parts, chassis components, interior panels.

- Multi-axis machining enables efficient production at scale.

Medical Devices

- Surgical instruments, implants, prosthetics, and diagnostic equipment.

- Requires biocompatible materials and ultra-high precision.

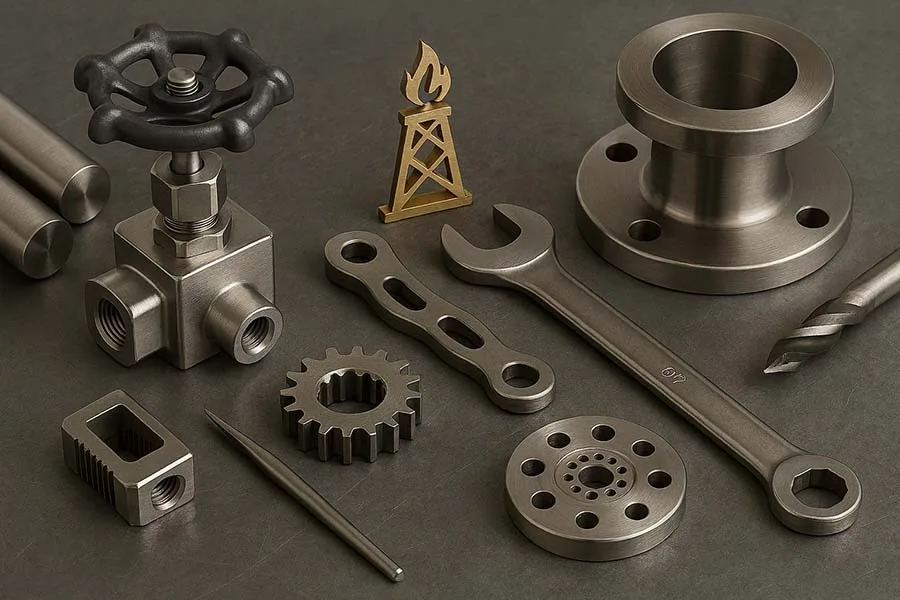

Energy & Oil Equipment

- Turbines, pumps, valves, offshore components.

- Tolerances are critical for durability and safety.

Key CNC Machining Processes

CNC machining processes are similar across industries but adapted for materials and geometry:

- Milling: Produces complex 3D parts like engine blocks or turbine blades.

- Turning: Cylindrical components, shafts, and pins.

- Drilling & Boring: Holes for fasteners, fluid channels, or precision assembly.

- Multi-Axis Machining: 4–5 axis CNC enables complex shapes and contours.

- Micro-CNC: Essential for medical devices and small electronic components.

Quality, Safety, and Compliance

Across all industries, CNC machining supports traceability, documentation, and inspection, ensuring:

- ISO 9001 / AS9100 / ISO 13485 quality standards

- Regulatory compliance: FAA, FDA, API standards

- Inspection techniques: CMM, laser scanning, non-destructive testing

Tip: CNC inherently improves reproducibility, reduces errors, and allows easy audit compliance.

Emerging Trends in CNC Materials & Applications

- Hybrid Manufacturing: CNC combined with additive manufacturing for complex geometries.

- Automation & AI Monitoring: Real-time tool wear detection and process optimization.

- Sustainability: Material efficiency, scrap reduction, and energy-efficient machining.

- Advanced Materials: High-performance alloys, reinforced polymers, and biocompatible composites.

CNC Materials & Applications FAQ

Conclusion

CNC machining is the foundation of modern industrial manufacturing, enabling precision, efficiency, and versatility across aerospace, automotive, medical, and energy sectors. Understanding materials, machining processes, and applications is essential for engineers, manufacturers, and decision-makers.

By exploring our CNC cluster, you can dive deeper into each application: