Introduction

CNC (Computer Numerical Control) technology has come a long way—from humble punched-tape systems to the intelligent, sensor-driven machining centers we see today. In this journey, innovators, breakthroughs, and industry demands combined to shape modern manufacturing. Let’s explore how CNC evolved—from analog beginnings through digital revolutions to the frontier of smart automation.

1. Early Beginnings: Punched Tape and the Birth of NC (1940s–1950s)

- Origins in Aerospace Needs

The concept of Numerical Control (NC) began in the 1940s when John T. Parsons conceptualized automated machining using coded instructions—a radical move away from manual tool handling. - From Concept to Prototype

Parsons, working with Frank Stulen, developed experimental systems using punched-card or punched-tape codes to control movement, especially for helicopter and aircraft component production. - MIT & the First NC Machine

In 1952, MIT—with U.S. Air Force backing—demonstrated the first NC machine, a modified Cincinnati Hydrotel milling machine, operated via punch-tape instructions. - First Commercial Machines

By the late 1950s, companies like Giddings & Lewis began selling NC machinery, marking the start of commercial adoption.

2. Rise of CNC and Programming Languages (1960s–1970s)

- From NC to CNC

The shift from punched-tape NC to Computer Numerical Control (CNC) in the 1960s brought real-time computing into the picture, paving the way for responsive and flexible machine control. - Introduction of Programming Languages

Douglas T. Ross developed APT (Automatically Programmed Tool) in 1956—a high-level language for driving NC machines—a foundational milestone. - Commercial CNC Machines

Around this time, commercial CNC models such as Kearney & Trecker’s Milwaukee-Matic II emerged, featuring modular tooling and multi-axis capabilities. By 1967, over 35,000 NC/CNC machines operated in U.S. industry.

3. Digital Control & CAD/CAM Integration (1970s–1990s)

- Microprocessor Revolution

In the 1970s, microprocessors made CNC control systems more compact, cost-effective, and efficient—ushering in wider adoption. - User Interfaces Go Visual

The 1980s introduced GUIs—replacing archaic command-line interfaces with intuitive, icon-driven displays—making machines friendlier to operators. - CAD/CAM Synergy

Late 1980s–1990s saw seamless integration of CAD (Computer-Aided Design) and CAM (Computer-Aided Manufacturing). Designers could model parts digitally and directly generate G-code, streamlining the design-to-production flow.

4. Expansion & Standardization (1980s–Present)

- FANUC’s Ascendance

In 1955, Fujitsu’s venture into NC grew into FANUC by 1972. By 1982, FANUC held about half the global CNC market—highlighting how software and control systems became critical enablers of CNC growth. - Haas Automation’s Role

Founded in 1983, Haas Automation introduced programmable machine tools and, in 1988, its first vertical machining center (VF-1)—bringing CNC capabilities to broader markets.

5. The Era of Smart, Connected CNC (2000s–Now & Beyond)

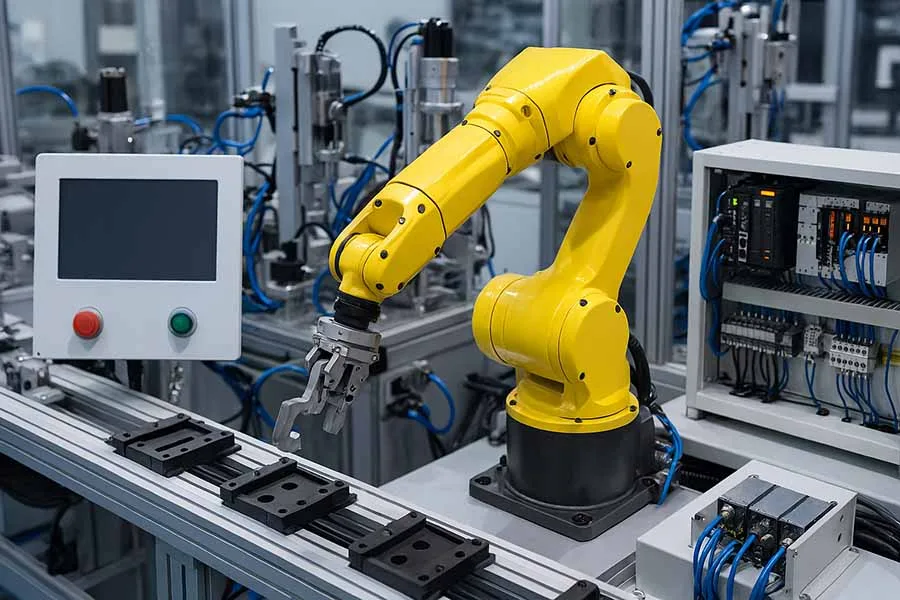

- IoT, Automation & Robotics

21st-century CNC systems now integrate IoT, robotics, and automation—enabling lights-out manufacturing, remote monitoring, and predictive maintenance. - Hybrid & AI-Enhanced Machining

CNC machines increasingly incorporate additive processes, sensors, and AI-driven optimization—culminating in adaptive, efficient, and smart machining operations.

Interesting Fact

- Power of APT Language

APT allowed tool paths to be defined with higher-level constructs—dramatically simplifying programming compared to raw G-code, yet still highly influential through the 1970s and beyond.

Lesser-Known Fact

- Early Commercial NC by Arma

Before MIT’s prototypes, Arma Corporation (a Bosch subsidiary) unveiled a numerically controlled lathe in 1950 (with automated “piano-roll” control)—an intriguing, often-overlooked milestone.

CNC Technology: From Punched Tape to Smart Machining FAQ

Want To Learn More?

- CNC Machining Fundamentals

- CNC Machining Explained: Precision, Process & Possibilities

- CNC Technology: From Punched Tape to Smart Machining

- Types of CNC Machines (Lathe, Mill, Router, Plasma, etc.)

- CNC Programming Languages (G-code, M-code)

- Most Common CNC Programming Errors

- CNC vs Manual Machining: Differences, Pros & Cons Explained

Conclusion

From punched tapes in MIT labs to AI-enhanced smart machining centers, CNC technology has undergone a remarkable journey. Each milestone—from NC prototypes, APT language, microprocessors, CAD/CAM, to modern automation—expanded CNC’s reach and impact. Today, CNC sits at the heart of precision manufacturing—efficient, adaptable, and ready to power the next industrial revolution.

Invitation to Readers:

What part of CNC history fascinates you most? Have you worked with legacy or modern CNC systems? Share your experiences in the comments, and don’t forget to share this post on social media to help others explore the evolution of CNC technology!