Introduction: The Industrial Automation Revolution

In today’s fast-paced manufacturing world, efficiency isn’t just a goal—it’s a necessity. Industrial automation solutions are transforming how factories operate, from simple assembly lines to complex robotic systems. These solutions reduce human error, enhance productivity, and help manufacturers stay competitive in a global market.

Whether you are in automotive, electronics, or general manufacturing, understanding the types and benefits of industrial automation is essential for staying ahead.

What Are Industrial Automation Solutions?

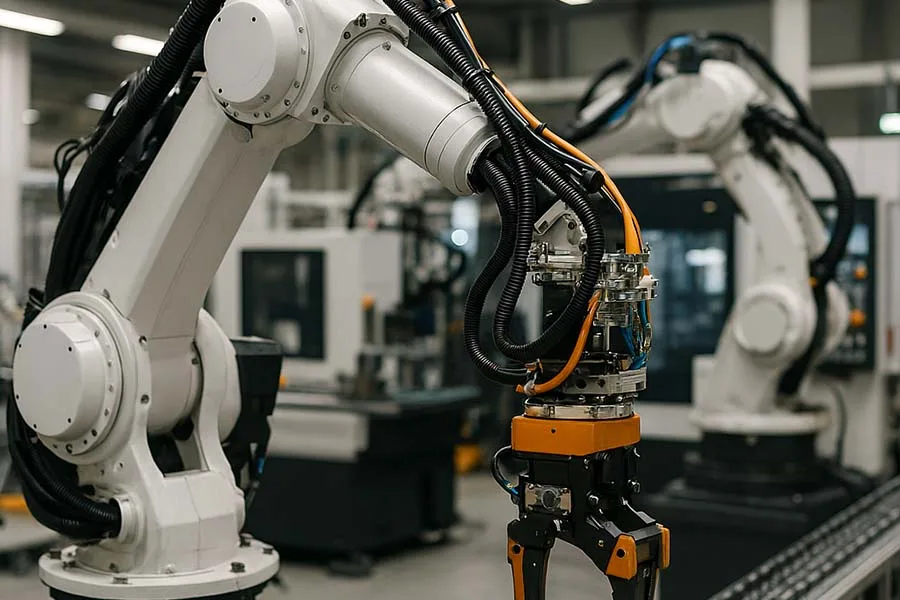

Industrial automation solutions refer to systems and technologies designed to automate manufacturing processes, minimizing manual intervention. They often combine hardware (robots, sensors, actuators) with software (control systems, analytics, AI) to optimize operations.

Key components include:

- Robotics – Automated machines performing tasks from welding to packaging.

- Programmable Logic Controllers (PLCs) – Brain of industrial machines, controlling operations efficiently.

- Human-Machine Interfaces (HMIs) – User-friendly interfaces that allow operators to monitor and control machines.

- Sensors and Actuators – Detect environmental changes and trigger precise machine responses.

- Industrial Software – Data analytics, process control, and predictive maintenance platforms.

Types of Industrial Automation

1. Fixed Automation

Ideal for high-volume production with repetitive tasks. Once configured, machines perform the same operation repeatedly with minimal flexibility. Example: Automotive assembly line robots.

2. Programmable Automation

Designed for batch production, allowing machines to switch tasks with reprogramming. Example: CNC machines in metal fabrication.

3. Flexible Automation

Highly adaptable systems that can handle multiple product variations without significant downtime. Example: Electronics assembly lines producing different devices on the same system.

4. Integrated Automation

Entire factory systems are networked, enabling Industry 4.0-level operations, including predictive maintenance, real-time analytics, and interconnected machines.

Benefits of Industrial Automation Solutions

- Increased Productivity: Machines can run 24/7, accelerating production.

- Improved Quality: Consistent, precise operations reduce defects.

- Cost Reduction: Lower labor costs and minimized waste.

- Safety Enhancement: Dangerous tasks can be automated, reducing workplace accidents.

- Data-Driven Decisions: Analytics platforms provide insights for process optimization.

Lesser-Known Fact: Some factories use AI-driven automation to predict equipment failures weeks in advance, saving millions in downtime.

Funny Fact: In some fully automated factories, robots now joke that humans are the “manual error factor” in the system!

Real-World Applications

- Automotive Industry: Robotic arms for welding, painting, and assembling car components.

- Food & Beverage: Automated filling, packaging, and quality control.

- Pharmaceuticals: Precision dosing, bottling, and lab automation.

- Electronics: Component assembly and soldering with extreme accuracy.

Challenges in Industrial Automation

While automation offers immense benefits, it’s not without challenges:

- High Initial Investment: Advanced machinery and software can be costly.

- Skilled Workforce Required: Engineers and technicians must operate and maintain complex systems.

- Integration Issues: Older equipment may not be compatible with new automation solutions.

- Cybersecurity Risks: Networked systems are vulnerable to cyber threats.

Future Trends in Industrial Automation

- AI and Machine Learning: Smarter machines capable of self-optimization.

- Collaborative Robots (Cobots): Robots working safely alongside human operators.

- IoT Integration: Real-time monitoring and predictive maintenance.

- Sustainability Focus: Energy-efficient automated systems reducing carbon footprint.

Industrial Automation Solutions FAQ

Further Read

- Industrial Automation Solutions

- Industrial Automation Systems: The Backbone of Modern Industry

- Process Automation in Manufacturing: The Key to Smarter Production

- Automation Companies to Watch in 2025 and Beyond

- Automation Machines for Industry: Types, Benefits, and Future Trends

- Automated Material Handling Solutions: Benefits, Types & Future Trends

- Automated Control Systems

- Industrial Automation Solutions: Transforming Modern Manufacturing

- Warehouse Automation Tools: Boosting Efficiency in Modern Warehouses

- Intelligent Automation Technologies: The Future of Industry

- Automated Packaging Systems

- Automation Case Studies

- Automation Trends 2025: What’s Next for Industrial Innovation

Conclusion

Industrial automation solutions are no longer optional—they are essential for modern manufacturing competitiveness. By combining robotics, intelligent software, and connected systems, manufacturers can improve productivity, safety, and quality while staying ahead of the competition.

Have you implemented automation in your facility? Share your experiences or questions in the comments below and join the conversation on how automation is reshaping industry!