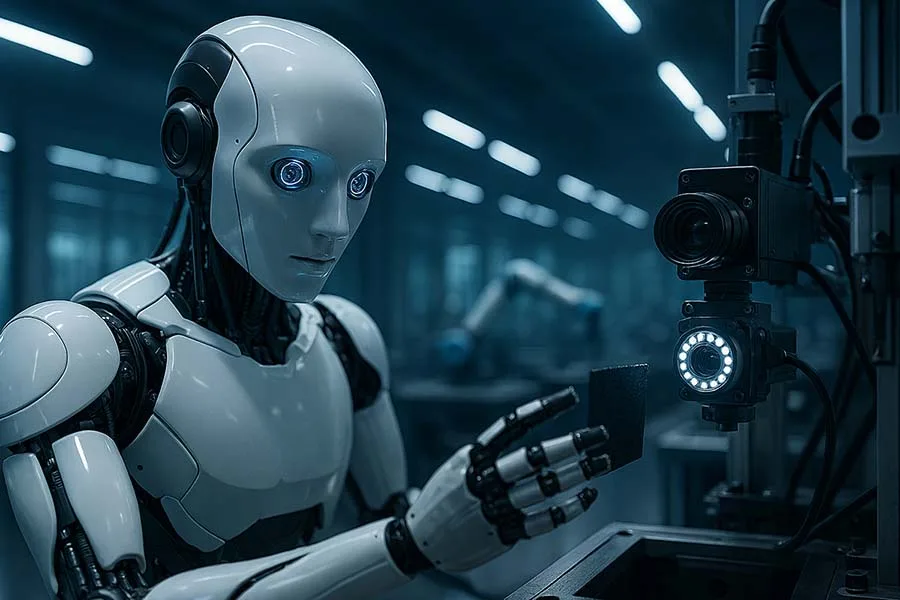

In today’s fast-paced industrial world, simply automating repetitive tasks isn’t enough anymore. Businesses are now turning to intelligent automation technologies, a powerful combination of artificial intelligence (AI), machine learning, robotics, and smart software that goes beyond routine operations. This evolution isn’t just about replacing human effort – it’s about transforming how industries operate, make decisions, and stay competitive.

What Is Intelligent Automation?

Intelligent automation (IA) is the next step beyond traditional automation. While standard automation handles predefined, rule-based tasks, intelligent automation adds decision-making capabilities powered by AI and machine learning.

Think of it this way:

- Traditional automation = “If this happens, do that.”

- Intelligent automation = “Analyze what’s happening, learn from it, and choose the best response.”

This distinction makes intelligent automation adaptable, scalable, and capable of handling complex processes that were once thought to require human judgment.

Core Technologies Behind Intelligent Automation

At the heart of intelligent automation are several key technologies working together:

Artificial Intelligence (AI) & Machine Learning (ML)

AI enables machines to simulate human intelligence, while ML allows them to continuously improve from data. In manufacturing, AI systems can predict machine failures before they happen or optimize production schedules in real-time.

Robotic Process Automation (RPA)

RPA automates repetitive digital tasks like data entry, reporting, and inventory updates. When combined with AI, RPA can adapt to exceptions, making it far more powerful than simple rule-based bots.

Industrial Internet of Things (IIoT)

Smart sensors and connected devices collect data across production lines, warehouses, and logistics. This data feeds into AI systems that analyze performance, detect anomalies, and enable predictive maintenance.

Cloud & Edge Computing

To process vast amounts of industrial data quickly, cloud computing provides scalable storage and computing power, while edge computing ensures fast, real-time responses on-site.

Applications in Industry

Intelligent automation is reshaping multiple sectors of industry. Some of the most impactful applications include:

Manufacturing & Assembly

- Automated robots that adjust operations based on sensor feedback.

- AI-driven production planning for efficiency and reduced waste.

Logistics & Supply Chains

- Smart warehouses with autonomous guided vehicles (AGVs).

- Real-time demand forecasting and inventory management.

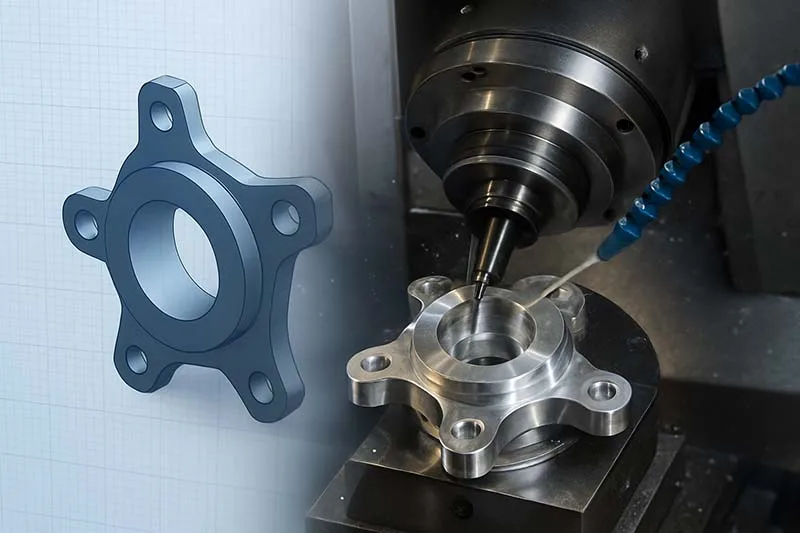

Quality Control & Predictive Maintenance

- Vision systems detecting micro-defects faster than the human eye.

- Predictive algorithms scheduling maintenance before breakdowns occur.

Energy Management

- Automated systems that balance energy loads.

- AI tools optimizing consumption for sustainability.

Benefits of Intelligent Automation

When implemented effectively, intelligent automation offers a range of business advantages:

- Efficiency & Cost Savings – Streamlined operations cut downtime and reduce costs.

- Error Reduction – AI-driven processes minimize human error and improve product quality.

- Scalability – Automated systems can scale up quickly to meet increased demand.

- Workforce Augmentation – Employees are freed from repetitive tasks, allowing them to focus on innovation and strategy.

Challenges and Considerations

Of course, no technology comes without hurdles. Companies adopting intelligent automation face challenges such as:

- High Upfront Costs – Initial investments in hardware, software, and integration.

- Cybersecurity Risks – More connected devices mean greater vulnerability.

- Workforce Adaptation & Training – Employees need to reskill for new roles.

- Integration with Legacy Systems – Many factories rely on outdated equipment that’s hard to connect.

Addressing these issues requires careful planning, strong leadership, and a commitment to ongoing training and security.

Future Outlook

The future of intelligent automation is both exciting and inevitable. We can expect:

- AI-driven Decision Making – Factories will increasingly rely on autonomous decision-making.

- Human-Machine Collaboration (Industry 5.0) – Robots and humans working side by side in harmony.

- Expansion Beyond Manufacturing – Healthcare, construction, and agriculture will adopt intelligent automation at scale.

In short, intelligent automation won’t just optimize industry – it will redefine it.

Intelligent Automation Technologies FAQ

Further Read

- Industrial Automation Solutions

- Industrial Automation Systems: The Backbone of Modern Industry

- Process Automation in Manufacturing: The Key to Smarter Production

- Automation Companies to Watch in 2025 and Beyond

- Automation Machines for Industry: Types, Benefits, and Future Trends

- Automated Material Handling Solutions: Benefits, Types & Future Trends

- Automated Control Systems

- Industrial Automation Solutions: Transforming Modern Manufacturing

- Warehouse Automation Tools: Boosting Efficiency in Modern Warehouses

- Intelligent Automation Technologies: The Future of Industry

- Automated Packaging Systems

- Automation Case Studies

- Automation Trends 2025: What’s Next for Industrial Innovation

Conclusion

Intelligent automation technologies are not just a trend – they are the backbone of the next industrial revolution. By combining AI, robotics, IoT, and smart data, industries can achieve unmatched efficiency, resilience, and innovation.

The companies that embrace this shift today will be tomorrow’s leaders. Those that delay may find themselves struggling to keep up.