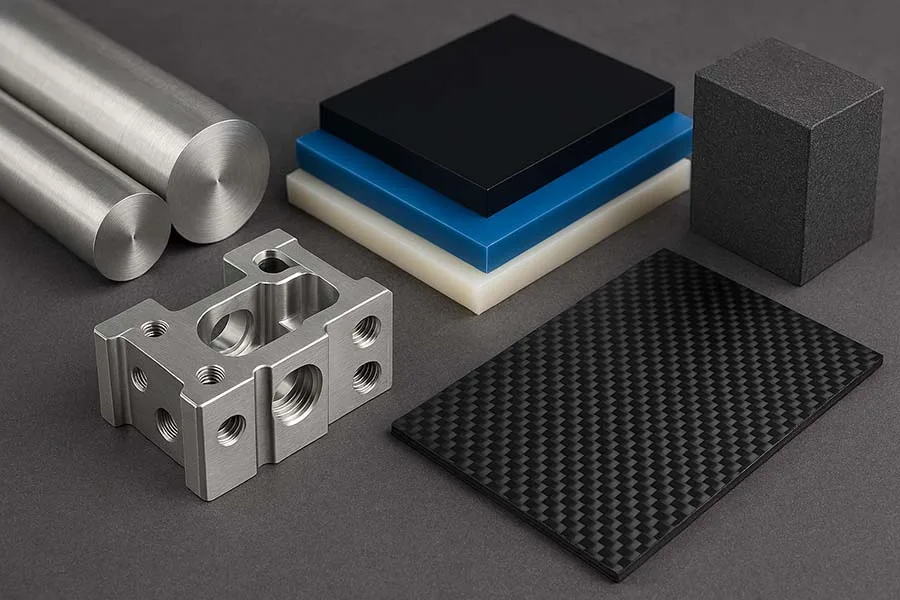

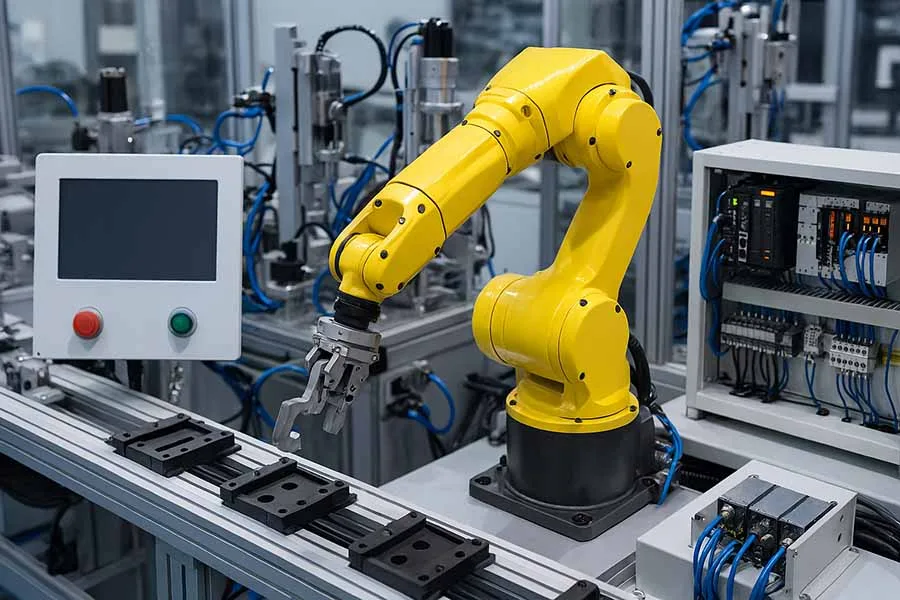

CNC machining is at the heart of modern manufacturing, from automotive components to aerospace parts and precise prototyping. But no matter how advanced your machine is, choosing the right material is critical. The material affects machinability, tool wear, cost, and ultimately the performance of the final part.

In this guide, we’ll explore the most commonly used materials in CNC machining—metals, plastics, and composites—highlighting their properties, applications, and key considerations to help you make informed decisions.

Metals in CNC Machining

Metals remain the most popular choice for CNC machined parts, offering durability, precision, and a wide range of mechanical properties. Here’s a closer look at the top metals used in machining:

Aluminum

- Properties: Lightweight, corrosion-resistant, excellent thermal and electrical conductivity.

- Machinability: Very good; easy on tools, allows high-speed cutting.

- Applications: Aerospace components, automotive parts, electronics housings.

Fun Fact: Aluminum is used in aerospace not just for its light weight, but also because it maintains strength at high altitudes.

Steel

- Types: Mild steel, stainless steel, tool steel.

- Properties: Strong, durable, high wear resistance.

- Machinability: Varies by type—mild steel is easy, tool steel is harder and can wear tools faster.

- Applications: Heavy machinery parts, industrial tools, structural components.

Titanium

- Properties: Extremely strong, corrosion-resistant, excellent strength-to-weight ratio.

- Machinability: More difficult than aluminum or steel; requires specialized tooling.

- Applications: Aerospace, medical implants, high-performance automotive components.

Lesser-Known Fact: Machining titanium generates heat quickly, so cooling and tool material selection are crucial to avoid part deformation.

Copper and Brass

- Properties: Excellent electrical and thermal conductivity, corrosion-resistant.

- Machinability: Brass machines very easily, copper slightly more challenging.

- Applications: Electrical connectors, plumbing components, decorative hardware.

| Metal | Density | Hardness | Machinability | Common Use |

|---|---|---|---|---|

| Aluminum | 2.7 g/cm³ | Medium | Excellent | Aerospace, automotive |

| Steel | 7.8 g/cm³ | High | Moderate | Industrial machinery |

| Titanium | 4.5 g/cm³ | High | Challenging | Aerospace, medical |

| Brass | 8.5 g/cm³ | Medium | Excellent | Electrical, decorative |

| Copper | 8.9 g/cm³ | Medium | Moderate | Electrical, plumbing |

Plastics in CNC Machining

Plastics are increasingly popular for prototyping, tooling, and lightweight industrial components. Their properties vary widely, but they generally offer ease of machining, corrosion resistance, and flexibility.

Common Plastics

- ABS (Acrylonitrile Butadiene Styrene): Durable, impact-resistant, widely used for prototyping.

- Nylon: Flexible, wear-resistant, ideal for gears and mechanical parts.

- POM/Delrin: Excellent dimensional stability, low friction, used in precision components.

- Polycarbonate: Tough and transparent, commonly used for safety guards and housings.

Applications: Prototyping, automotive interior parts, tooling jigs, industrial components.

Tip: Plastics machine faster and produce less tool wear than metals, but overheating can cause melting or surface defects.

Composite Materials

Composite materials combine fibers and resins to produce lightweight yet strong components. They are widely used in high-performance industries but can be more challenging to machine.

Popular Composites

- Carbon Fiber: Extremely strong and light; can wear down cutting tools quickly.

- Fiberglass: Durable, resistant to corrosion, slightly easier to machine than carbon fiber.

- Reinforced Plastics: Combine plastics with fibers for enhanced strength and stability.

Applications: Aerospace, sporting equipment, automotive panels, specialized industrial parts.

Practical Tip: Always use sharp, high-quality tools and proper dust collection when machining composites to maintain part quality and safety.

Choosing the Right Material for Your Project

Selecting the right CNC material is about balancing properties with project requirements:

- Strength vs Weight: Titanium and composites are strong and light, steel is heavy but very durable.

- Machinability: Aluminum and plastics are easier to machine, saving time and tool wear.

- Cost: Metals like steel are cost-effective for high-volume production; specialty alloys and composites are more expensive.

- Application Environment: Consider corrosion, temperature, and chemical exposure.

Internal Link Opportunity: For a deeper dive into the CNC process itself and how material choice affects cutting parameters, check out our CNC Machining Processes & Technologies guide.

Read more about CNC Materials & Applications

- CNC Materials & Applications

- CNC in Energy & Oil Equipment

- Materials Used in CNC Machining

- CNC in Aerospace Manufacturing: Precision, Materials, and Technology

- CNC in Automotive Production

- CNC in Medical Devices

Conclusion

From metals like aluminum, steel, and titanium, to plastics and composites, every material brings its own advantages and challenges to CNC machining. By understanding properties, machinability, and applications, you can make smarter choices that save time, reduce costs, and ensure high-quality results.

CTA: Ready to take your CNC skills further? Explore our full NC Machining Processes & Technologies or check out our Industrial Tools Academy to start learning today.