Introduction: The Modern Warehouse Revolution

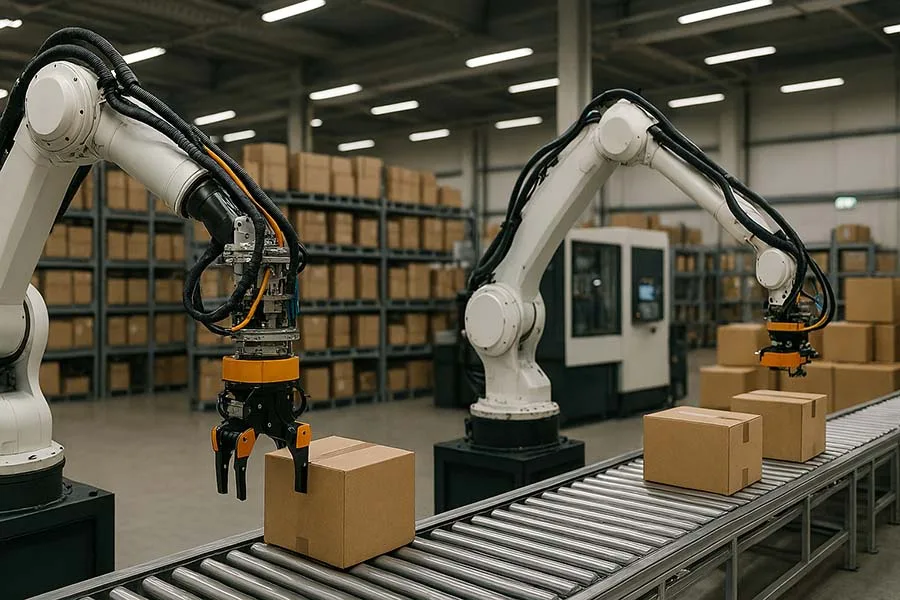

Warehouses are no longer just storage spaces – they are dynamic hubs of logistics, fulfillment, and distribution. In the age of e-commerce and rapid delivery expectations, manual operations can no longer keep pace. Warehouse automation tools are transforming these spaces, helping businesses reduce errors, increase throughput, and optimize labor costs.

From robotic picking systems to smart conveyors, modern warehouses are embracing automation to stay competitive and scalable.

What Are Warehouse Automation Tools?

Warehouse automation tools encompass hardware and software solutions designed to automate storage, retrieval, and handling of goods. They help warehouses operate efficiently by reducing manual tasks, streamlining workflows, and improving accuracy.

Common warehouse automation tools include:

- Automated Guided Vehicles (AGVs): Self-navigating vehicles that transport goods safely throughout the warehouse.

- Conveyor Systems: Efficiently move products between zones for packing, sorting, or shipping.

- Automated Storage and Retrieval Systems (AS/RS): Mechanized systems for storing and retrieving inventory with high precision.

- Robotic Picking Systems: Robots equipped with vision systems to pick, pack, and sort products.

- Warehouse Management Software (WMS): Tracks inventory, optimizes picking routes, and manages workflow.

- Barcode Scanners & RFID Systems: Ensure accurate tracking of inventory in real time.

Key Benefits of Warehouse Automation Tools

- Increased Efficiency: Automation speeds up picking, packing, and shipping processes.

- Reduced Errors: Robots and scanners ensure precise inventory handling.

- Labor Cost Savings: Fewer manual labor hours required for repetitive tasks.

- Enhanced Safety: Automated vehicles and conveyors reduce workplace accidents.

- Scalable Operations: Easily adapt to seasonal demand or business growth.

Lesser-Known Fact: Some warehouses now use AI-powered systems to predict stock shortages before they happen, ensuring continuous availability.

Funny Fact: In some automated warehouses, AGVs “race” each other for efficiency, making human supervisors joke that the robots are having more fun than the staff!

Popular Warehouse Automation Tools in Action

1. Automated Guided Vehicles (AGVs)

AGVs transport materials safely and efficiently across the warehouse, following pre-programmed paths. They reduce forklift traffic and prevent collisions.

2. Conveyor Systems

Conveyors move items between storage, packing, and shipping areas seamlessly. Modern systems include sorting mechanisms, allowing packages to reach the right destination automatically.

3. Robotic Picking Systems

Equipped with cameras and AI, robotic arms can pick items of different shapes and sizes, pack them into boxes, and prepare them for shipment—all without human intervention.

4. Automated Storage and Retrieval Systems (AS/RS)

AS/RS systems store products in dense configurations, maximizing storage space. They can automatically retrieve items on-demand, speeding up fulfillment processes.

5. Warehouse Management Software (WMS)

WMS platforms integrate all warehouse operations, optimizing workflows, tracking inventory, and providing real-time analytics for smarter decision-making.

Challenges in Warehouse Automation

While the benefits are significant, warehouse automation comes with challenges:

- High Initial Investment: Automation systems require upfront capital.

- Integration Complexity: Existing warehouse setups may need upgrades for compatibility.

- Workforce Adaptation: Employees need training to work alongside automated systems.

- Maintenance Requirements: Robotics and conveyors require regular maintenance to avoid downtime.

Future Trends in Warehouse Automation

- AI-Powered Optimization: Advanced algorithms for dynamic picking and routing.

- Collaborative Robots (Cobots): Human-friendly robots working safely alongside staff.

- IoT Integration: Real-time monitoring of inventory, equipment, and warehouse conditions.

- Sustainable Warehousing: Energy-efficient conveyors, electric AGVs, and smart lighting reduce environmental impact.

Warehouse Automation Tools FAQ

Further Read

- Industrial Automation Solutions

- Industrial Automation Systems: The Backbone of Modern Industry

- Process Automation in Manufacturing: The Key to Smarter Production

- Automation Companies to Watch in 2025 and Beyond

- Automation Machines for Industry: Types, Benefits, and Future Trends

- Automated Material Handling Solutions: Benefits, Types & Future Trends

- Automated Control Systems

- Industrial Automation Solutions: Transforming Modern Manufacturing

- Warehouse Automation Tools: Boosting Efficiency in Modern Warehouses

- Intelligent Automation Technologies: The Future of Industry

- Automated Packaging Systems

- Automation Case Studies

- Automation Trends 2025: What’s Next for Industrial Innovation

Conclusion

Warehouse automation tools are revolutionizing how modern logistics operate. By integrating robots, conveyors, automated storage systems, and advanced software, warehouses can improve efficiency, reduce errors, and enhance safety.

Call to Action: Are you planning to implement automation in your warehouse? Share your experiences, questions, or challenges in the comments below and be part of the discussion on modern warehouse efficiency!