🔧 Introduction: Why Terminology Matters in Fastening

Let’s be honest—many people use “bolt” and “screw” interchangeably. Some even throw in “stud” just to sound technical. But in industrial settings, knowing the exact difference isn’t just about semantics—it’s about safety, performance, and compliance.

This guide breaks down the differences between bolts, screws, and studs—with examples, use cases, and visual comparisons—so your assemblies stay strong, safe, and spec-compliant.

🆚 The Fastener Face-Off: Bolt vs Screw vs Stud

| Feature | Bolt | Screw | Stud |

|---|---|---|---|

| Threading | External | External | External on both ends (or full) |

| Head | Yes | Yes | No |

| Requires Nut | Yes (usually) | No (usually) | Yes (both ends) |

| Installs Into | Unthreaded hole + nut | Pre-threaded or self-threading | Threaded hole + nut |

| Common Use | Machine assembly, structures | Panels, enclosures, plastics | Engine blocks, flanges |

🔩 What Is a Bolt?

A bolt is a threaded fastener with a head, designed to pass through an unthreaded hole and be secured on the other side with a nut.

🔹 Key Features:

- Tightened by turning the nut

- Designed for shear and tensile strength

- Often used with washers

🔹 Best Used For:

- Structural frames

- Equipment assemblies

- High-load joints

🔹 Example:

A hex bolt securing a steel beam to a structural bracket using a flange nut and washer.

✅ Pro Tip: Use bolts when the clamping force is more important than thread engagement in the base material.

🔩 What Is a Screw?

A screw is a threaded fastener that usually doesn’t require a nut. It is typically driven directly into the material, either by forming its own thread (self-tapping) or engaging a pre-tapped hole.

🔹 Key Features:

- Tightened by turning the head

- Holds by thread friction or form

- Often used for ease of assembly/disassembly

🔹 Best Used For:

- Electronics

- Sheet metal

- Wood and plastic components

🔹 Example:

A self-tapping screw joining two aluminum panels in an HVAC system.

✅ Use Tip: Choose screws when the joint needs to be opened frequently, or where a nut can’t be accessed on the backside.

🔩 What Is a Stud?

A stud is a threaded rod—usually with no head—that screws into a tapped hole on one end and is fastened with a nut on the other end.

🔹 Key Features:

- Permanent thread engagement in base material

- Ideal for repeated disassembly

- Allows precise preload

🔹 Types of Studs:

| Stud Type | Description | Use Case |

|---|---|---|

| Fully Threaded | Threads along the entire length | Threaded rods, general purpose |

| Double-End Stud | Threads on both ends, unthreaded middle | Engine cylinder heads |

| Tap-End Stud | One end with longer thread | Flanges, pressure vessels |

🔹 Best Used For:

- Automotive engines

- Pressure vessels

- Flanged pipe joints

✅ Engineer’s Tip: Use studs when the base material is soft or the fastener will be installed and removed multiple times. It reduces wear on the tapped hole.

🧠 Interesting Fact

In engines, studs are often preferred over bolts because they reduce the risk of stripping the threads in the engine block during repeated maintenance!

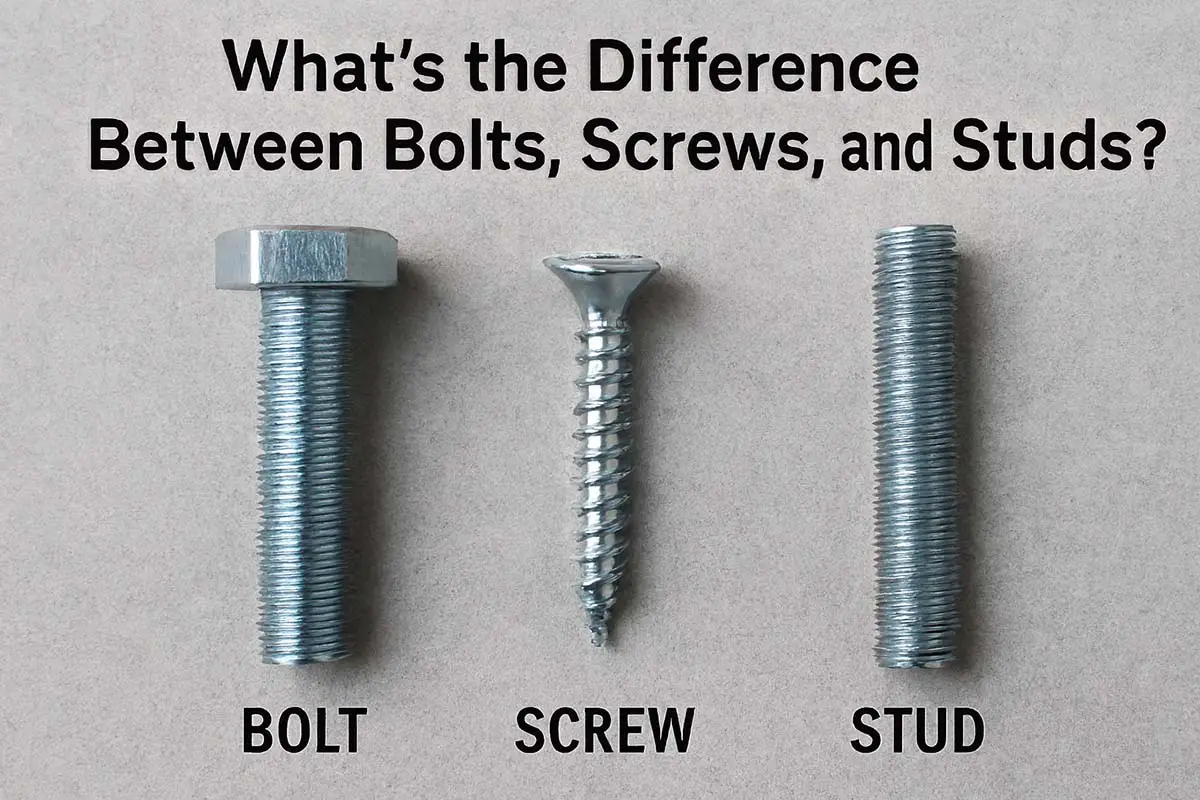

🛠️ Visual Comparison: Bolt vs Screw vs Stud

| Fastener | Head? | Nut? | Installed Into | Reusability | Ideal For |

|---|---|---|---|---|---|

| Bolt | Yes | Yes | Unthreaded hole | High | High-strength assemblies |

| Screw | Yes | No | Tapped hole or soft material | Moderate | Light-to-medium duty |

| Stud | No | Yes (both ends) | Tapped hole + nut | Very high | Engines, flanges, vibration zones |

💡 Choosing the Right Fastener

Ask These 5 Questions:

- Is one or both sides of the joint accessible?

- Will the joint be disassembled often?

- Is thread strength in the base material a concern?

- Do you need a high clamp load or preload?

- Is vibration a factor?

| Situation | Use This |

|---|---|

| You can’t reach the back side | Screw |

| You need max strength and a nut | Bolt |

| You’ll assemble/disassemble many times | Stud |

🔗 Related Reads

- Understanding Bolt Grades and Strength Classes (Metric & SAE)

- Common Types of Industrial Fasteners and When to Use Them

- What’s the Difference Between Bolts, Screws, and Studs?

- Fastener Materials and Coatings Explained

- How to Prevent Fastener Failure in the Field

- How to Read Bolt Head Markings: Grade, Manufacturer & More

- Explained: Coarse vs Fine Threads in Industrial Fastening

- What’s the Difference Between Bolts, Screws, and Studs?

- Should You Buy Fasteners in Bulk or Kits?

🧯 Safety & Mistake to Avoid

🚫 Don’t confuse bolts with screws in specs. A screw may strip a plain hole not meant for thread engagement. A bolt may fail without a nut if torque is applied incorrectly.

✅ Conclusion: A Small Difference That Makes a Big Impact

Bolts, screws, and studs may look similar at a glance—but their roles, strengths, and installation methods are radically different. In industrial environments, understanding these differences means better performance, less failure, and smoother assembly.

💬 What’s Your Go-To Fastener?

Are you a “stud guy” when it comes to high-performance builds, or do you stick to hex bolts for everything?

Comment below with your favorite fastener and why—and don’t forget to share this article with fellow engineers, fabricators, and industrial problem-solvers.