Your go-to reference for mastering CNC terminology

Whether you’re evaluating machines, reading spec sheets, or training new operators, CNC terminology can feel like a foreign language. This glossary breaks down the most essential terms so you can speak CNC with confidence—whether you’re on the shop floor or making strategic decisions.

A–C

- Axis A direction along which the CNC machine moves—typically X (left/right), Y (forward/back), and Z (up/down).

- Backlash The small amount of lost motion due to gaps between mechanical parts, often corrected in software.

- Ball Screw A precision screw mechanism that converts rotary motion into linear motion with minimal friction.

- CAM (Computer-Aided Manufacturing) Software used to generate toolpaths and instructions for CNC machines.

- CNC (Computer Numerical Control) A system that automates machine tools using programmed commands.

- Coolant Liquid or gas used to reduce heat and friction during machining.

- Cycle Time The total time required to complete one machining operation or part.

D–H

- Datum A reference point or surface from which measurements are taken.

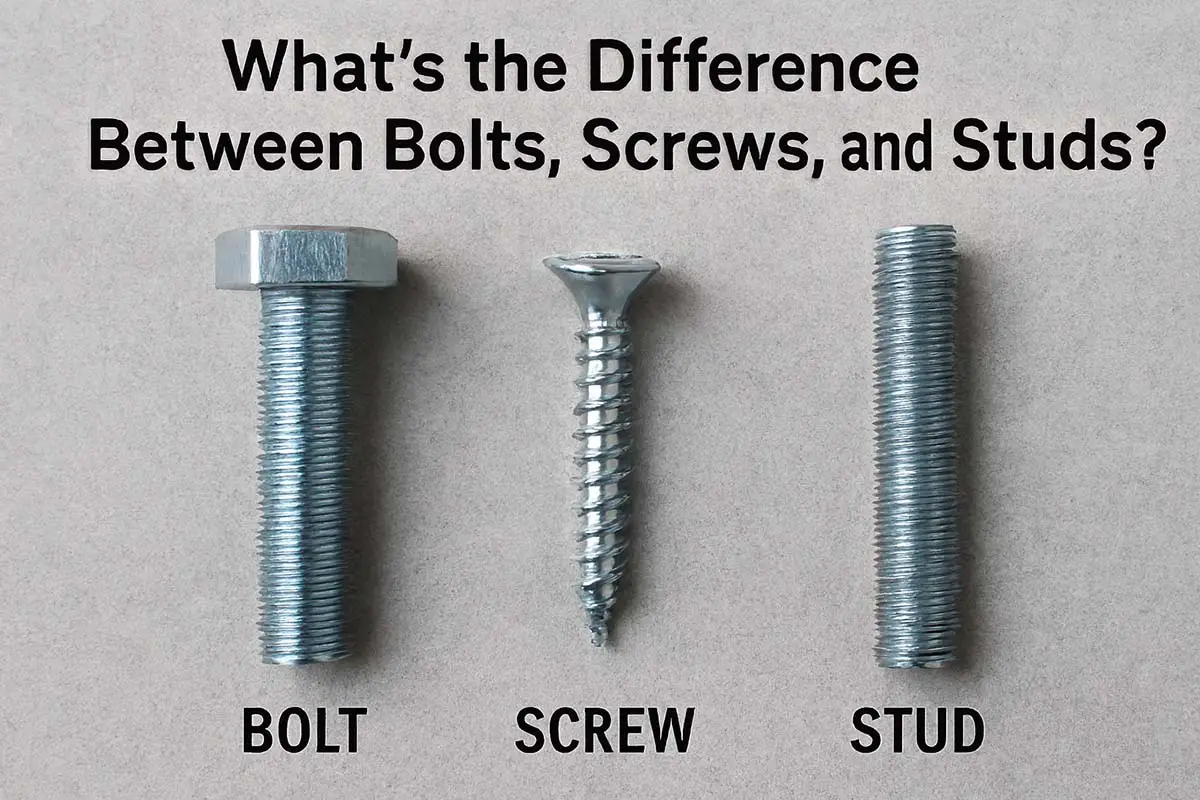

- Drill Bit A cutting tool used to create cylindrical holes.

- End Mill A cutting tool used for milling operations, typically with cutting edges on the sides and bottom.

- Feed Rate The speed at which the cutting tool moves through the material.

- Fixture A device used to securely hold a workpiece during machining.

- G-Code The programming language used to control CNC machines, specifying movements and operations.

- HMI (Human-Machine Interface) The control panel or screen used by operators to interact with the CNC system.

I–M

- Interpolation The process of calculating intermediate points to create smooth toolpaths.

- Jogging Manually moving the machine along its axes using the control panel.

- Kerf The width of material removed by a cutting process.

- Lead-In / Lead-Out The path the tool takes before entering and after exiting the cut to ensure smooth transitions.

- Machine Zero The fixed origin point of the machine’s coordinate system.

- M-Code Commands used to control machine functions like coolant, spindle on/off, or tool changes.

- Mill A machine tool used to remove material by rotating a cutting tool.

O–S

- Offset A value used to adjust the position of tools or workpieces for accurate machining.

- Post-Processor Software that converts CAM data into machine-specific G-code.

- RPM (Revolutions Per Minute) The speed at which the spindle or cutting tool rotates.

- Spindle The rotating component that holds and drives the cutting tool.

- Step-Over The lateral distance between passes of the cutting tool during milling.

- Surface Finish The texture and smoothness of a machined surface.

T–Z

- Taper A gradual decrease in diameter along the length of a tool or hole.

- Toolpath The programmed route the cutting tool follows during machining.

- Tool Wear The gradual degradation of a cutting tool due to use.

- Tolerance The allowable deviation from a specified dimension.

- Work Coordinate System (WCS) A user-defined coordinate system used to position the workpiece.

- Workholding Devices used to secure the workpiece during machining.

- Zero Point The starting point for machining operations, often set by the operator.

Further Read

- CNC Machining Training & Support: Your Complete Resource

- Glossary of CNC Terms

- FAQs About CNC Machining – Answers to the Most Common Questions

- Best Practices for CNC Safety: Protecting Operators & Machines

- CNC Operator Certification Paths: Which One Is Right for You?