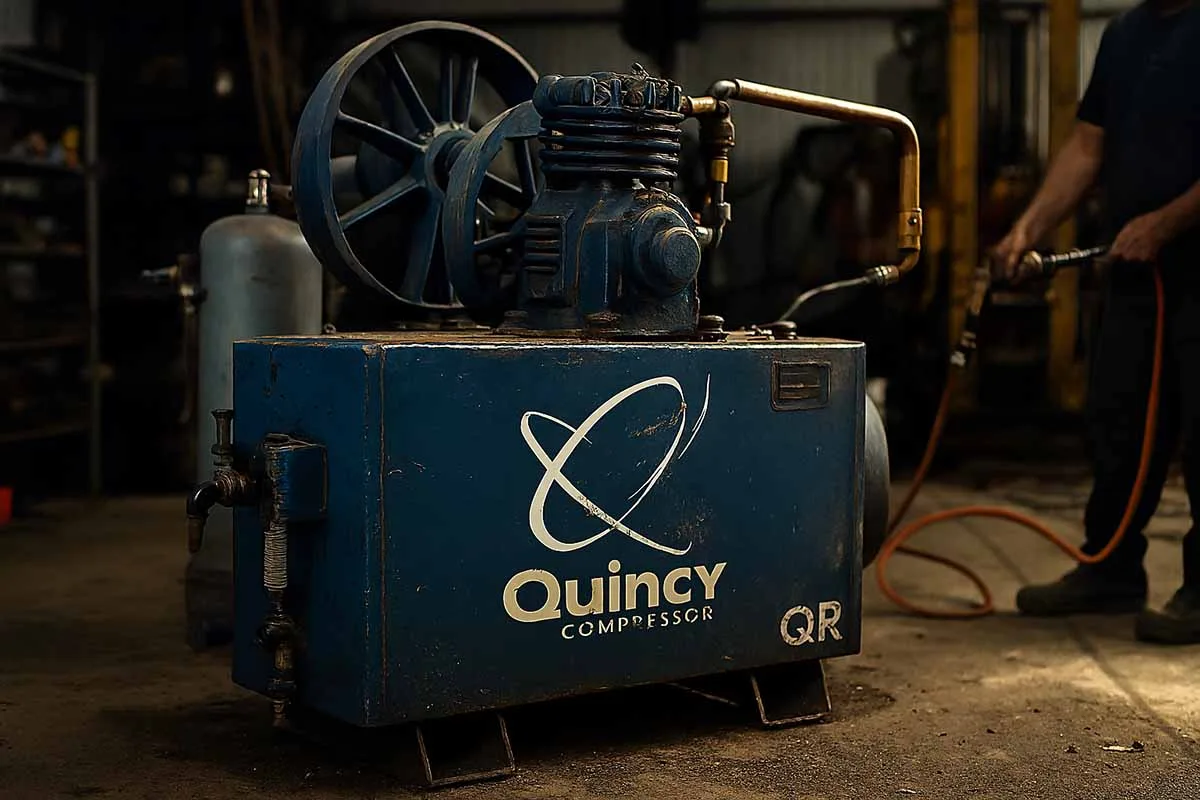

Quincy QR-25 Review: Heavy-Duty Reciprocating Compressor for Industrial Reliability

Introduction

The Quincy QR-25 is a two-stage, pressure-lubricated reciprocating air compressor designed for demanding industrial applications. With horsepower ranging from 1 to 25 HP and pressure ratings up to 500 psig, it’s engineered for durability, efficiency, and minimal downtime. Known for its cast-iron construction and rebuildable components, the QR-25 is a legacy product that continues to outperform in harsh environments.

If you’re running a manufacturing line, a maintenance bay, or a facility that demands consistent high-pressure air, the QR-25 is a proven workhorse. In this review, we’ll explore its features, compare it to alternatives, and help you decide if it’s the right fit for your operation.

Key Features & Technical Specifications

| Feature | Details |

|---|---|

| Horsepower Range | 1–25 HP |

| Max Pressure | Up to 500 psig |

| Duty Cycle | 100% continuous |

| Lubrication | Pressure-lubricated with positive displacement oil pump |

| Construction | Cast-iron cylinders, crankcase, valve seats |

| Startup | Loadless starting via intake unloaders |

| Cooling | Intercooler with large circular fins |

| Maintenance | Spin-on oil filters, easy-access valve pockets |

| Warranty | 5-Year True Blue Warranty (with authorized startup) |

The QR-25 runs at slower speeds to reduce wear and increase CFM per horsepower. Its oversized roller bearings, rifle-drilled crankshaft, and aluminum connecting rods with full-flow lubrication ensure long-term reliability.

Pros & Cons

| Pros | Cons |

|---|---|

| Extremely durable cast-iron build | Higher noise level than rotary screw models |

| Rebuildable components | Larger footprint for lower HP models |

| High pressure output (up to 500 psig) | Requires regular oil checks and filter changes |

| Loadless starting reduces motor wear | Not ideal for mobile or space-constrained setups |

| Long service life—often decades | Higher upfront cost vs splash-lubricated units |

Comparisons to Alternatives

| Model | Type | Max Pressure | Maintenance | Ideal For |

|---|---|---|---|---|

| Quincy QR-25 | Reciprocating | 500 psig | Moderate | Heavy-duty industrial use |

| Quincy QT Series | Reciprocating | ~175 psig | Frequent | Light-duty shops |

| Ingersoll Rand T30 | Reciprocating | ~250 psig | Moderate | General industrial use |

| Atlas Copco G-Series | Rotary screw | ~150 psig | Minimal | Quiet, continuous-duty environments |

The QR-25 stands apart for its pressure-lubricated design and rebuildability. While rotary screw models offer quieter operation, they lack the raw durability and pressure range of the QR-25.

Use Cases: Who Should Buy It (and Who Shouldn’t)

Ideal Buyers:

- Industrial plants needing high-pressure air for pneumatic tools

- Maintenance bays with long runtime cycles

- Facilities in harsh environments (dust, heat, vibration)

- Buyers seeking long-term ROI and rebuildable equipment

Not Ideal For:

- Small workshops with intermittent use

- Mobile setups or space-limited environments

- Users prioritizing ultra-quiet operation

Quincy Compressor QR-25 FAQ

Interesting Fact

The QR-25’s crankshaft is rifle-drilled and counter-weighted to reduce vibration and extend bearing life—a design rarely seen in standard piston compressors.

Lesser-Known Fact

Unlike many competitors, the QR-25 uses lapped cast-iron valve seats for complete sealing, reducing air loss and improving efficiency over time.

Read More

- Quincy QGS Series Review: Rotary Screw Compressors

- Quincy QR-25 Review: Heavy-Duty Reciprocating Compressor

- Quincy QGS Series Review: Quiet Rotary Screw Compressors

- Quincy Compressor Maintenance Guide: Keep Your QGS and QR-25 Running at Peak Performance

- Quincy QR-25 vs Ingersoll Rand 2475

- Atlas Copco GX vs Quincy QGS: Rotary Screw Compressors Compared

- Atlas Copco

- How to Troubleshoot Common Compressor Problems

- How to Improve Energy Efficiency of Your Compressor

Conclusion: Should You Buy the Quincy QR-25?

If your operation demands high-pressure, long-lasting compressed air with minimal downtime, the Quincy QR-25 is a legacy-grade solution. It’s not just built to perform—it’s built to last. With rebuildable components, pressure lubrication, and a reputation for reliability, it’s a smart investment for serious industrial buyers.

Have experience with the QR-25? Drop a comment below or share your setup on LinkedIn or Reddit. Your insights help others make informed decisions—and spotlight the tools that keep industry moving.