Introduction

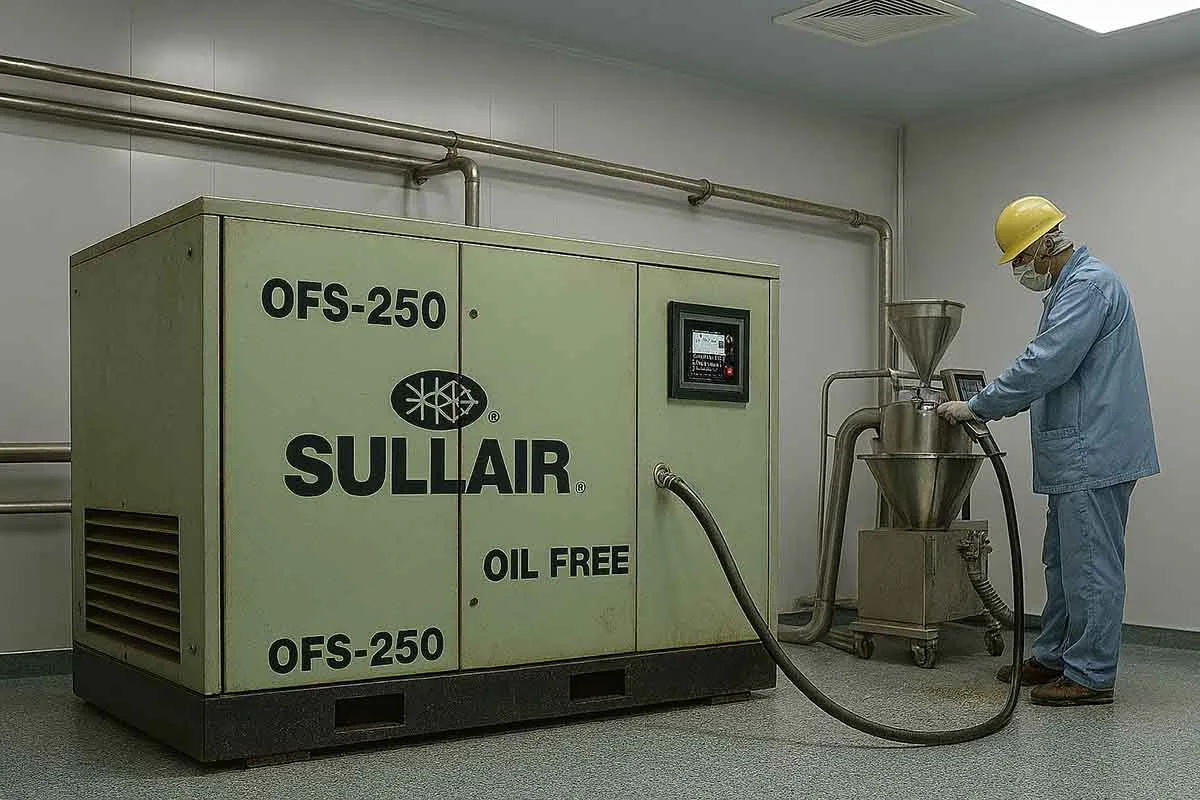

The Sullair OFS Series is a line of oil-free rotary screw compressors engineered for industries where air purity is mission-critical. Certified to ISO 8573-1 Class 0 standards, these machines deliver 100% oil-free air—essential for pharmaceuticals, food and beverage, electronics, and automotive painting. With horsepower ranging from 100 to 350 hp, the OFS Series combines precision engineering, corrosion-resistant components, and advanced controls in a compact footprint.

If your operation can’t afford contamination, the OFS Series is your safeguard.

Key Features & Technical Specifications

- Horsepower Range: 100–350 hp (75–261 kW)

- Air End:

- Asymmetrical rotors with FDA-approved PTFE coating

- Anti-friction bearings rated for 100,000+ hours

- Compression Stages: Two-stage rotary screw for optimal efficiency

- Air Quality: ISO 8573-1 Class 0 certified—no oil aerosols, vapors, or particulates

- Controller:

- WS Input/Output module

- Backlit LCD panel with built-in sequencing and alarms

- Variable Speed Drive (Optional): Up to 60% turndown for energy savings

- Thermal Stability: Jacketed rotor housings and coated air passages

- Footprint: Compact design for cleanroom or tight-space installations

Pros and Cons

| Pros | Cons |

|---|---|

| 100% oil-free air—ideal for contamination-sensitive environments | Higher initial cost than lubricated compressors |

| FDA-approved corrosion-resistant coatings | Requires stricter maintenance protocols |

| Compact footprint for cleanrooms | Not suitable for heavy-duty outdoor use |

| Built-in sequencing and smart controls | Limited to specific industries |

| Optional VSD for energy savings | May require specialized installation expertise |

Comparisons to Alternatives

- Atlas Copco ZR Series: Also Class 0 certified, but Sullair’s PTFE-coated rotors offer longer corrosion resistance.

- Ingersoll Rand Nirvana Oil-Free: Strong on energy efficiency, but OFS wins on rotor durability and control interface.

- Kaeser CSG Series: Excellent for pharma, but OFS offers more compact installation options and easier service access.

Use Cases: Who Should Buy It?

Ideal for:

- Pharmaceutical cleanrooms

- Food and beverage packaging lines

- Electronics and semiconductor manufacturing

- Automotive paint shops

- Textile production requiring contaminant-free air

Not ideal for:

- General-purpose workshops or construction sites

- Applications where oil carryover is acceptable

- Outdoor or mobile setups

Real-Life User Cases

- Czech Republic: A pharmaceutical lab installed two OFS250 units to meet EU GMP standards—reported zero contamination events over 18 months.

- Italy: A pasta manufacturer in Bologna uses OFS Series compressors to maintain hygiene during packaging—praised for quiet operation and compact footprint.

- Netherlands: A semiconductor plant in Eindhoven integrated OFS units with VSD, achieving 22% energy savings during variable load cycles.

Sullair OFS Series Review FAQ

Interesting Fact

The OFS Series uses FDA-approved PTFE coatings not just on rotors, but also on internal air passages—ensuring corrosion resistance throughout the entire compression path.

Lesser-Known Fact

Its anti-friction bearings are designed for an L10 life of over 100,000 hours—meaning 90% of bearings will last that long or longer under rated conditions.

Further Read

- Sullair LS Series Compressor Review

- Sullair 185 Portable Compressor Review

- Sullair OFS Series Review

- How to Maintain Sullair Compressors

- Kaeser CSD vs. Sullair LS Series

- Sullair 185 vs. Kaeser M Series

- How to Troubleshoot Common Compressor Problems

- How to Improve Energy Efficiency of Your Compressor

Conclusion

The Sullair OFS Series is a precision instrument for industries where air purity isn’t optional—it’s essential. If your operation demands Class 0 air, this compressor delivers it with durability, intelligence, and efficiency. Have you worked with the OFS Series in your facility? Share your experience in the comments and help others navigate the world of oil-free air. And if this review helped you, pass it along to your network—especially those in pharma, food, or electronics.